14

8 Service, Maintenance

When servicing the unit please observe the safety regulations in

chapter 4.

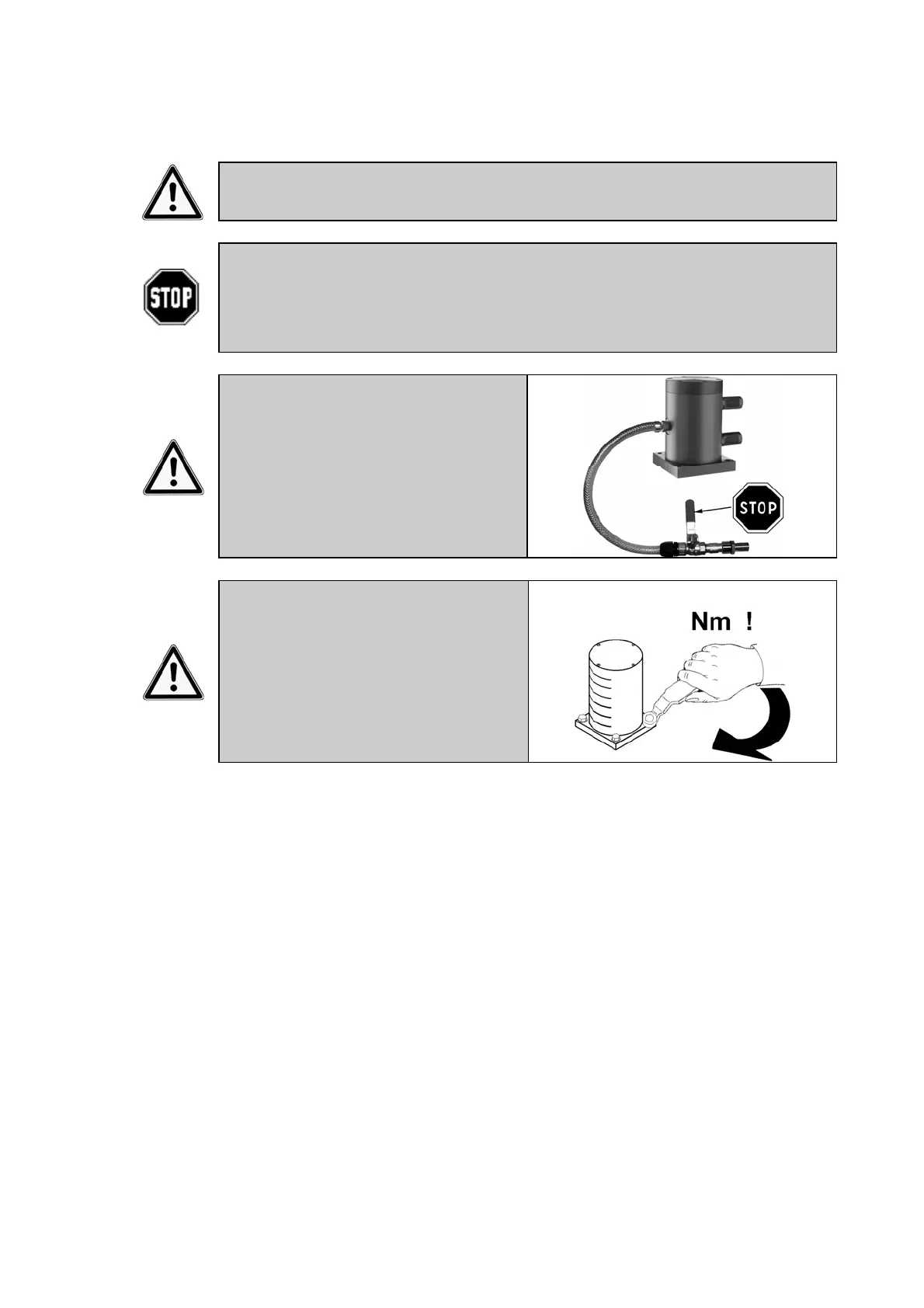

Retightening:

Screw connections must be checked and, if necessary, retightened after

1 hour of operation (after initial start-up) and then at regular intervals

(normally each month). On this occasion the specified torque must be

observed (see chapter 6).

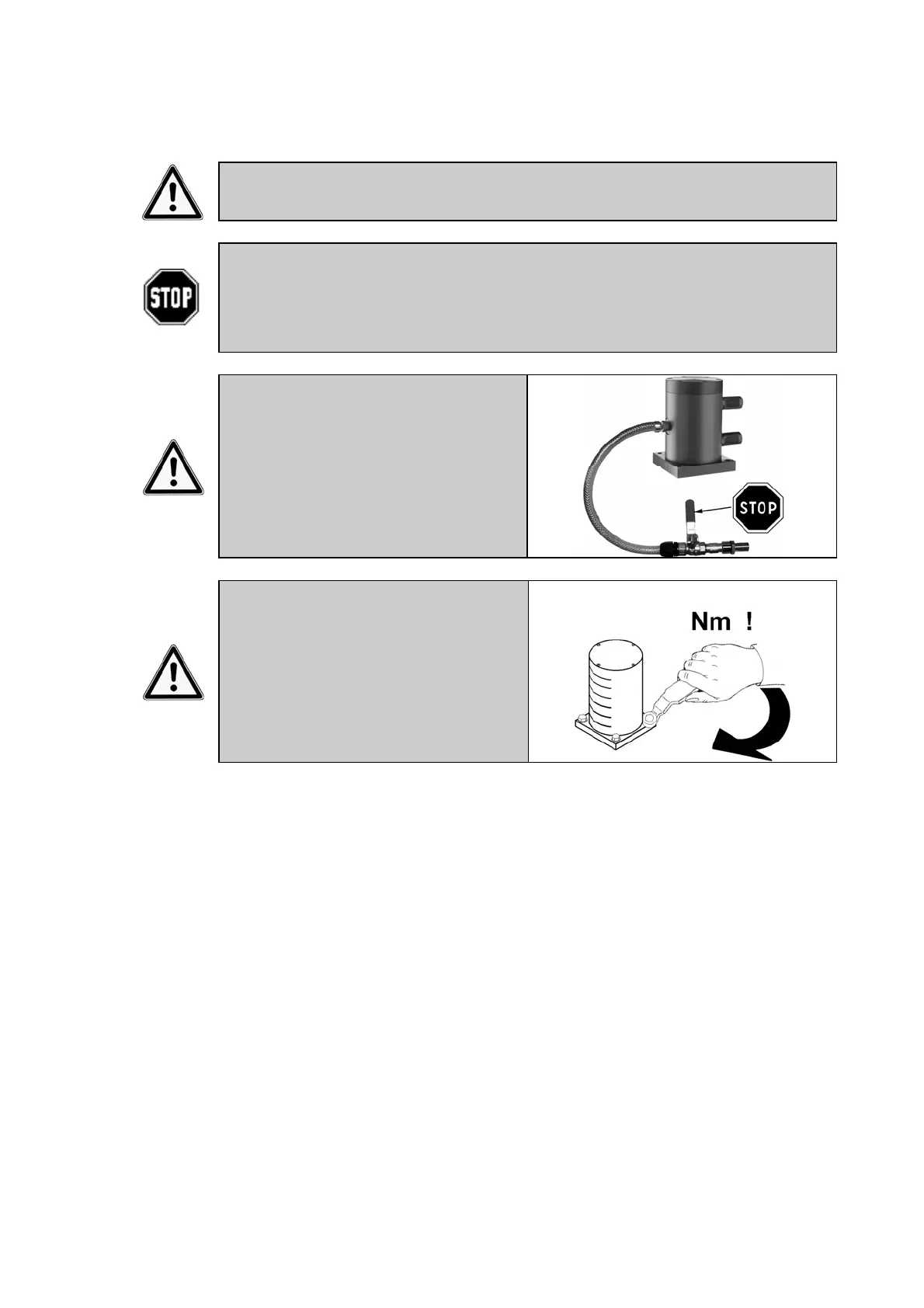

Before starting inspection or service

work shut off the compressed air or

nitrogen supply and secure it

against unintended activation!

Check fastening of vibrator, air

connection incl. upstream service

unit and silencer – preferably at

monthly intervals.

Jan. / Feb. / ...

Mist lubricator:

With a lubricator connected in series

make sure that it works as specified

(contents diminishing? number of

drops/h?). Top up oil.

Filter:

Empty the filter when required, clean

the filter insert (wash out).

Cleaning

All NTS vibrators can be externally

cleaned with pressure water, as long

as the exhaust air is discharged

through a hose or the exhaust opening

is closed. Pressure water must not

enter through the silencer into the

piston chamber.

Contamination

Especially on oil free operated units

(NTS of group 1) a film may form,

which slows the vibrator down.

If this is noticed (power drop, possible

stand-still) the unit must be opened

and cleaned inside. The film must be

cleaned off with an oiled cloth from the

inside of the housing and from the

piston.

Further notes can be found in chapter

9 „Troubleshooting“.

The maintenance intervals mainly

depend on the purity of the

compressed air or nitrogen.

Loading...

Loading...