15

9 Troubleshooting

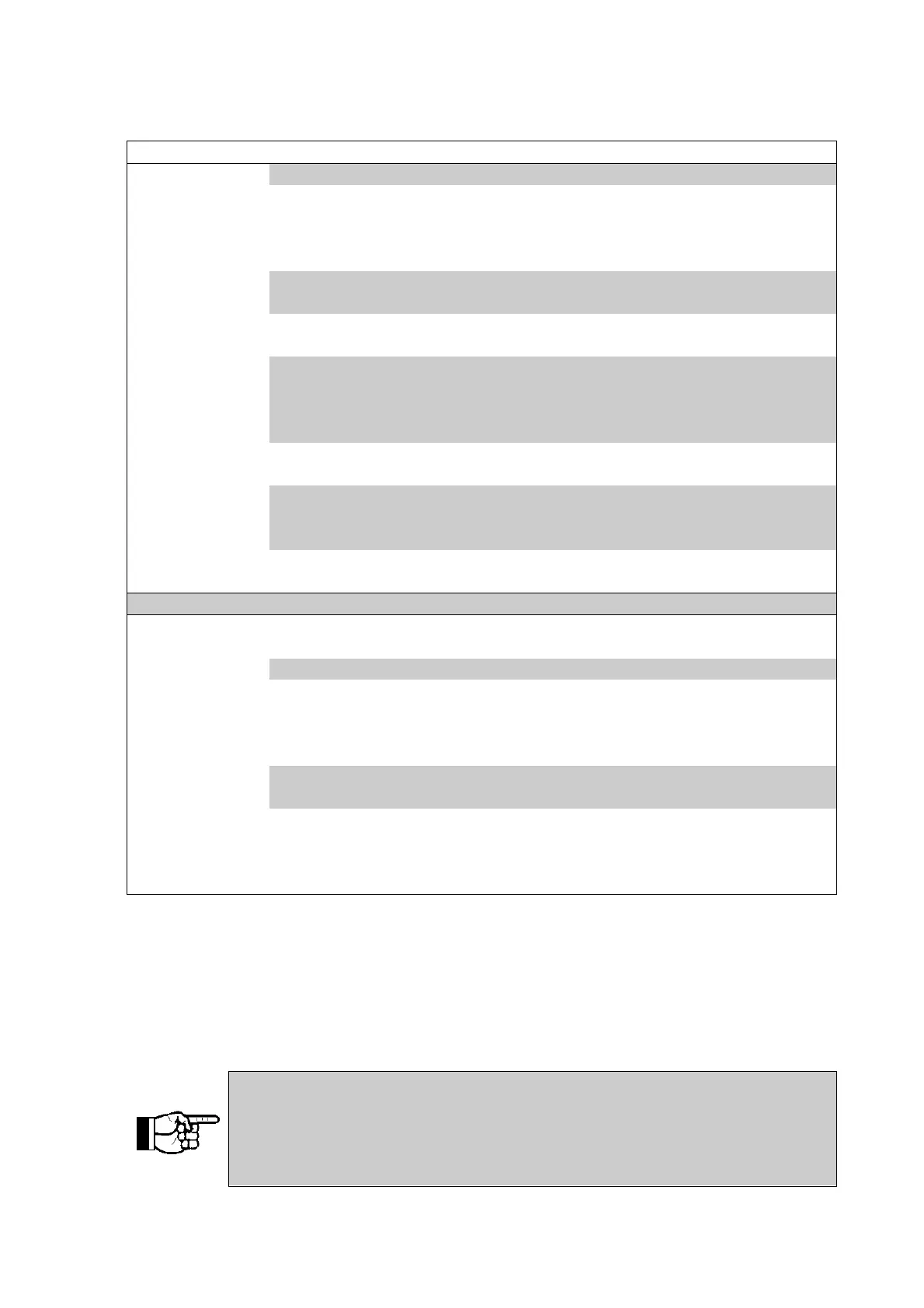

Fault Possible cause Remedy

No starting Silencer Clean the silencer

Air supply Check pressure on unit! Pressure high

enough? Check valve. A 3/2-way valve

is strictly required, so that the supply

line to the unit is ventilated.

Cover loose

leaking cover will cause standstill of

the vibrator Tighten the screws.

Line cross-sections too

small

Observe minimum cross-sections, see

specifications under „Installation“

Line between valve and

NTS too long

Causes slow starting and possible

standstill of piston in central position.

If necessary, install a pilot-controlled

3/2-way air valve in front of the vibrator

Exhaust air excessively

throttled

Open the throttle further. Check

silencer (sufficient air flow?).

Grommet has too long

thread

This may deform the housing (if this

has already happened, return the unit

to Netter GmbH!).

Spanning due to

installation

Check whether the contact surface is

even.

Rattling Screws loose Check the fastening screws

Power drop No lubrication Check function of lubricator if

lubricated compressed air is specified.

Unit soiled Dismantle, remove dirt film.

Wear Check unit and piston for visible wear

(if wear is found return the unit to

Netter GmbH!). See also note in

chapter 10 „Spare parts“.

Design: Check size of unit. Has the size been

chosen correctly?

Pressure too low Check the pressure at the inlet of the

unit (!) during operation. If necessary

increase the pressure. Line cross-

sections OK?

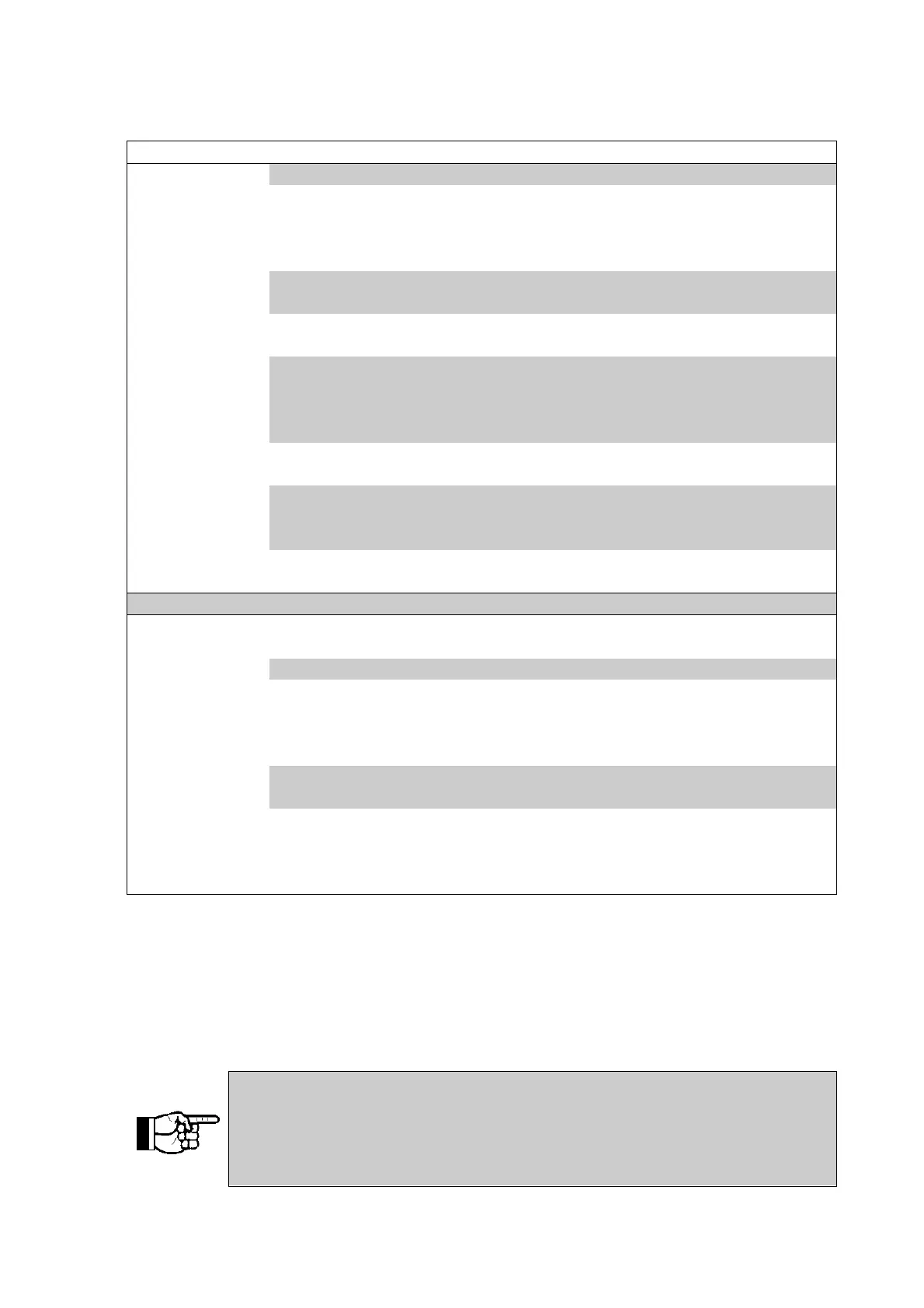

10 Spare Parts

When ordering spare parts please give the following details:

1. Type of unit

2. Description of spare part

3. Required quantity

Please note: Piston and housing are matched to each other and can

only be delivered together.

In order to assure compliance with the technical performance data

synchronously operated vibrators should always be replaced together. If this

is neglected, the new vibrator will adapt its power to the weaker vibrator.

Loading...

Loading...