7

4 Safety

NTS vibrators work with

compressed air or nitrogen.

Make sure the compressed air or

nitrogen supply is switched off

during installation.

Disconnect the supply lines (quick

coupling) before starting other work

on vibrators and supply lines.

Before starting operation all hoses

must be tightly connected.

A pressurized hose coming loose

can cause severe injury.

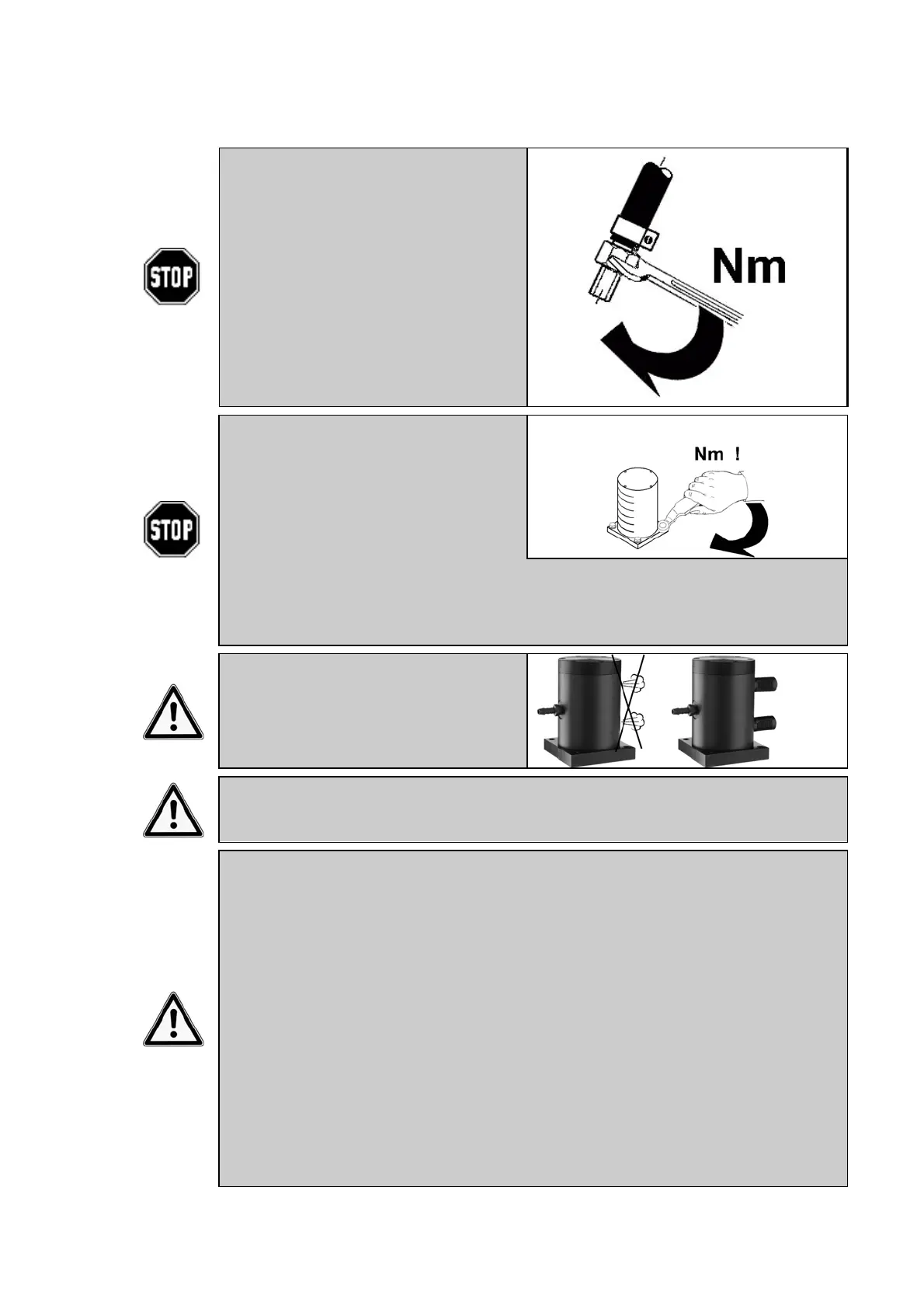

Vibrator as well as part of the

structure can detach because of

vibration. Falling parts can cause

damage to persons and material.

Screw retention components and/or

Loctite or similar must be used.

Jan. / Feb. / ...

Screw connections must be checked and, if necessary, retightened after 1

hour of operation and then controlled at regular intervals (normally each

month).

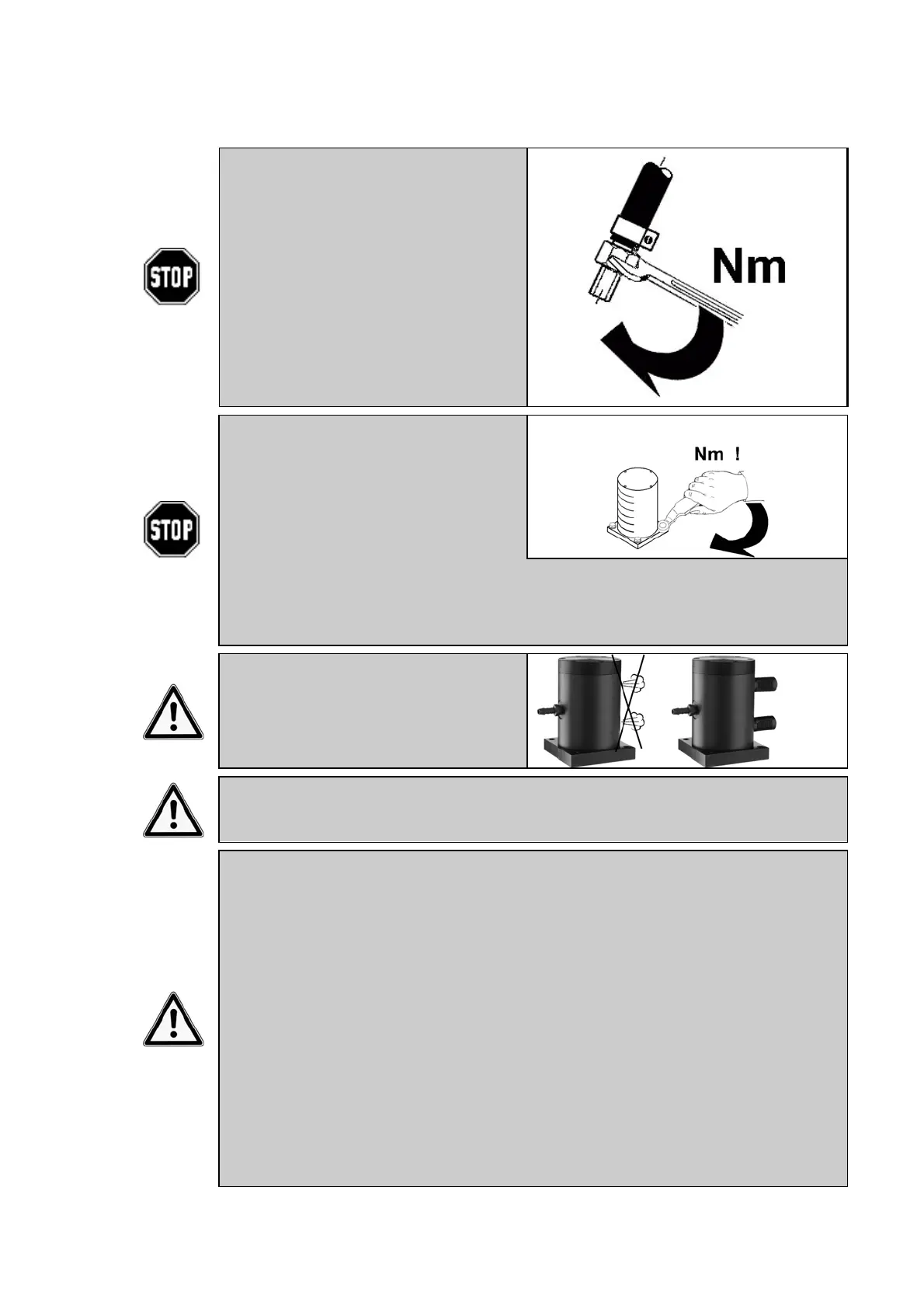

In critical installation situations the unit must be secured with a steel rope.

Silencer:

Operation without silencer should

be avoided in order to protect the

environment against high noise

values.

Technical changes to the equipment may effect the characteristics of the

vibrators or even damage the units and cause the rejection of any

warranty claims.

Permissible operating conditions:

Operating pressure:

2 bar to 6 bar*

Operating pressures must not be exceeded or fallen short of.

Ambient temperature:

5°C to 60° C*

Operating temperatures must not be exceeded or fallen short of.

Lubrication:

If advised by application engineers of Netter GmbH and in compliance with

locally specified conditions, vibrators of group 1 may be operated without

oil. (Exception 1: In case of freeze-dried air and under extreme ambient

conditions, Exception 2: NTS 21/04).

Units of group 2 and the NTS 21/04 must only be operated with lubricated

compressed air or lubricated nitrogen.

*) Higher operating pressures and temperatures are only permitted after consultation and written confirmation by

application engineers of Netter GmbH.

Loading...

Loading...