3-1

SECTION 3

LUBRICATION

Adequate lubrication and maintenance on a regular

schedule is vital to maintaining your equipment. To

ensure long service and efficient operation, follow the

lubrication and maintenance schedules outlined in

this manual. The use of proper fuels, oils, grease and

filters, as well as keeping the systems clean, will also

extend machine and component life.

IMPORTANT: Always use genuine New Holland

replacement parts, oils and filters to ensure proper

operation, filtration of engine and hydraulic systems.

See your New Holland dealer for additional oil

quantities.

GENERAL INFORMATION

Regular lubrication is the best insurance against

delays and repairs. Proper lubrication will extend

machine life. Refer to the following charts for

lubricants and service intervals.

IMPORTANT: Failure to complete the required

maintenance at the recommended intervals can

cause unnecessary downtime and premature wear

of components.

The intervals listed in the Lubrication Chart are

guidelines to be used when operating in normal

conditions. Adjust the intervals for operating in

adverse environmental and working conditions. The

intervals should be shortened for sandy, dusty and

extremely hot operating conditions.

WARNING

Observe these safety precautions before per-

forming lubrication and maintenance.

1. Shut off engine.

2. Disengage all drives.

3. Lower all attachments to the ground or raise

and engage all locks.

4. Close all shields opened and reinstall any

shields removed for lubrication and mainte-

nance proposes.

Failure to comply could result in death or serious

injury.

WARNING

Some illustrations in this manual show shields

opened or removed to show areas being

serviced. Replace all shields before operating

this machine. Failure to comply could result in

death or serious injury.

Always clean the area around dipsticks, fill caps, and

check plugs when checking fluid levels. Failure to

clean these areas may allow contamination to enter

the system. Drain, flush and refill the system anytime

you suspect it is contaminated.

Grease Fittings

Wipe dirt from fittings before greasing.

Pump fresh grease into fitting to adequately lubricate

the component and force out any contamination from

the grease passage.

Wipe off excess grease.

Use a grease gun containing clean high grade of

multipurpose grease.

Chains

Stop all drives before lubricating chains.

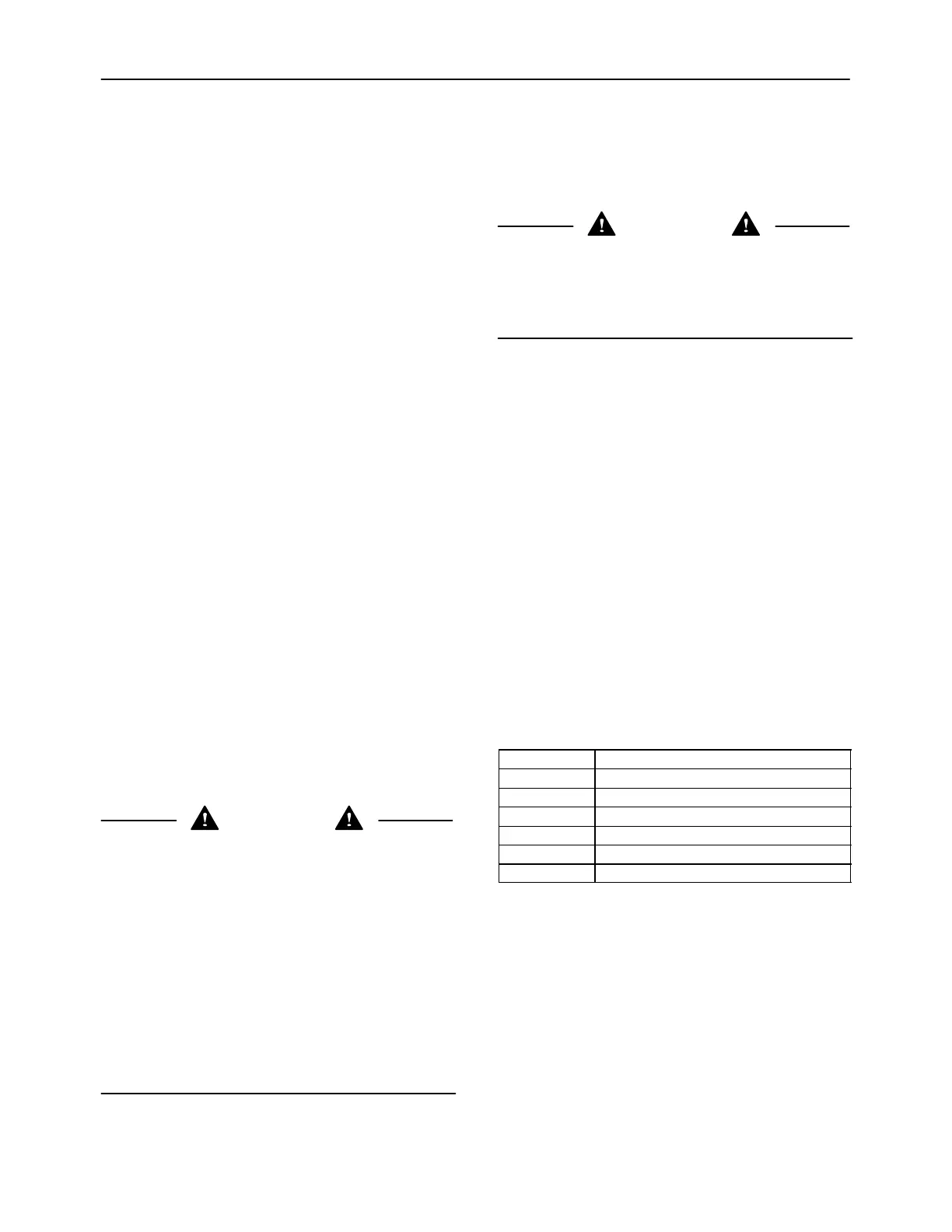

Lubricant Type and Description

Hydraulic Oil MULTI G 134

MULTI G

Gear Oil HYPOIDE 90 GEAR LUBE

HYPOIDE SSL GEAR LUBE (SYNTHETIC)

Grease GR--9 MULTI--PURPOSE GREASE

HI--TEMP GREASE

Loading...

Loading...