Subject to alterations Page 11 of 33

Duct connection

Ducting and fittings with rubber seals of tightness class B are recommended. It is also advisable

that all duct connections to Compact S be made with approx. 1m of soundproofed flex tube in order

to dampen sound emission.

D

ucting should be cut to length using a hacksaw or angle grinder and laid in accordance with the

design drawing. Ducting is usually either attached to rafter feet using perforated strip or suspended

in fitting strip. Avoid pinching the ducting in any way and any unnecessary bends.

T

he ducting must be insulated. Sometimes, standard loft insulation can be used for the purpose.

All ducting should be insulated with 100mm mineral wool to prevent heat loss and condensation.

Such insulation requirements also apply to soundproofed flex tubing. It is recommended that two

layers of 50mm insulating material be used. If ducting is installed in an unheated room, it is inad-

visable to switch the system off for prolonged periods as air from heated rooms will rise into the

ducting and condensate, thus possibly causing moisture problems.

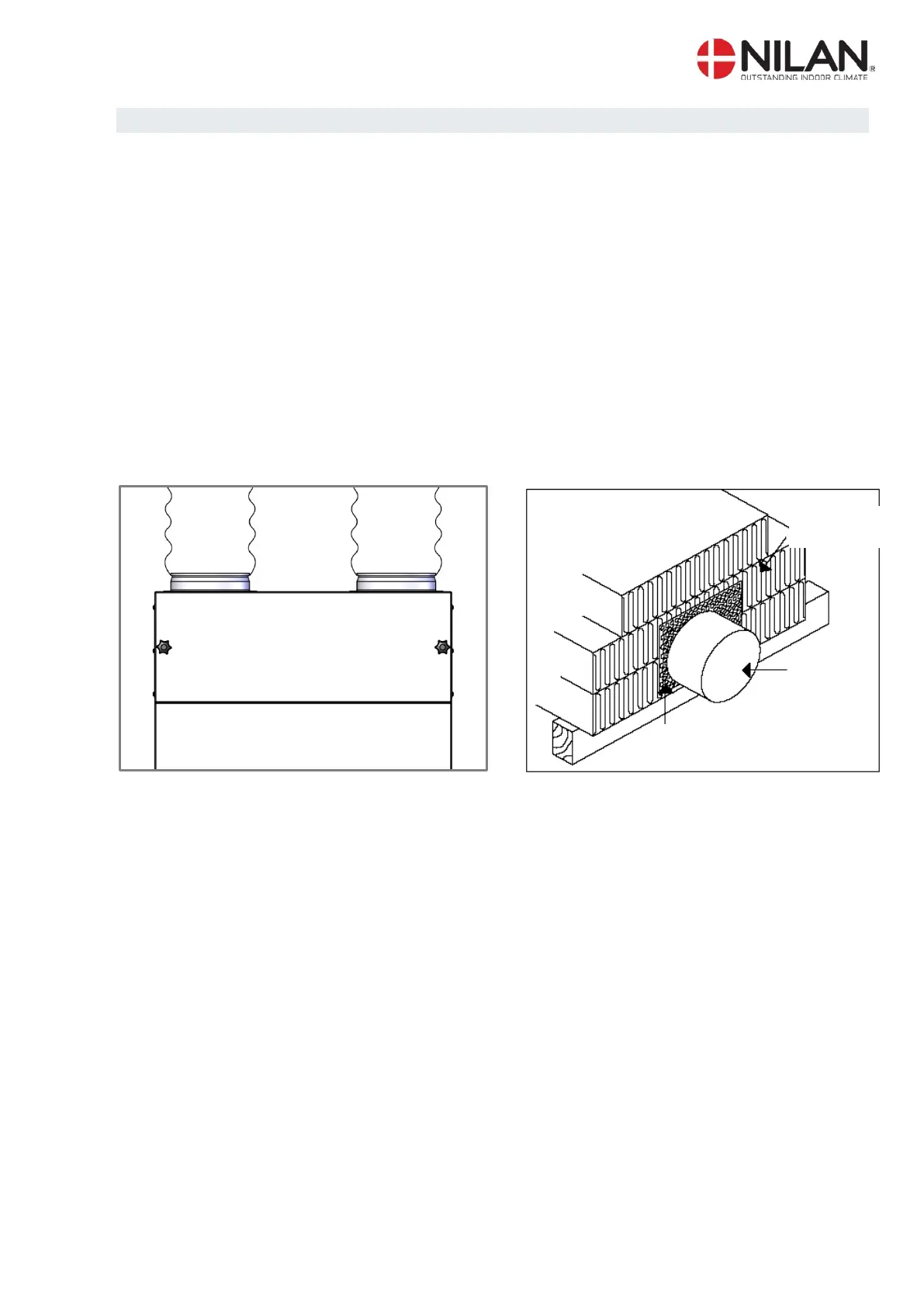

Figur 7: Flexible connection Figur 8: Insulation of ducting

T

he discharge duct leads the exhaust air (from which the system has recovered the energy it con-

tained) to the outside through the roof or outer wall. It is important that the roof stack or wall grille

has at least the same area as the duct immediately ahead of the stack or grille. Any contraction will

cause unnecessary pressure drop, which may reduce ventilation capacity.

Holes for inlet and exhaust valves should be cut to fit the frame of the valve concerned. Secure the

valve frame in position using screws and then attach the valve. Where the valves should be posi-

tioned depends on room design and use. It is, for example, inadvisable to install inlet valves

immediately above where people usually sit as inlet air may sometimes be perceived as a draught.

material

cm connec-

tion is

recommended.

Loading...

Loading...