4 - 11

4 System Design

G5-series Linear Motors/Servo Drives With Built-in EtherCAT Communications

4-1 Installation Conditions

4

4-1-3 Ironless Linear Motor Installation Conditions

z Cooling of Motor Coil Unit

• The Motor Coil Unit becomes hot during operation. For the Motor Coil Unit, install a moving table

(radiator plate) of the recommended dimensions or larger to provide sufficient heat dissipation into

the air.

• To provide good heat dissipation, reduce the thermal resistance by applying thermal conductive

silicon between the Motor Coil Unit and the moving table.

• Provide adequate ventilation as required to prevent an excessive rise of the ambient temperature

because heat is dissipated in the air.

• If the rise of the ambient temperature must be suppressed for a certain application, or if the size of

the moving table is smaller, configure a separate cooling system to cool the Motor Coil Unit.

z Rigidity of Linear System

The response performance of a linear system is affected by the rigidity of the Linear Slider. Ensure

that the rigidity is appropriate for the required performance. If a gain is set to higher than the

machine rigidity, the vibration occurs.

Take the following measures to improve rigidity.

• Use preloaded linear guides. This makes the Linear Slider highly rigid with less play in the

mechanical system.

• Ensure the rigidity of the base material to which the Linear Slider is secured.

The materials in descending order of rigidity: granite, steel, and aluminum.

• The moving table must have a sufficient thickness to prevent deformation and vibration.

• Install the Magnet Track and external encoder in a straight and parallel line.

• Install the external encoder as close to the Motor Coil Unit as possible.

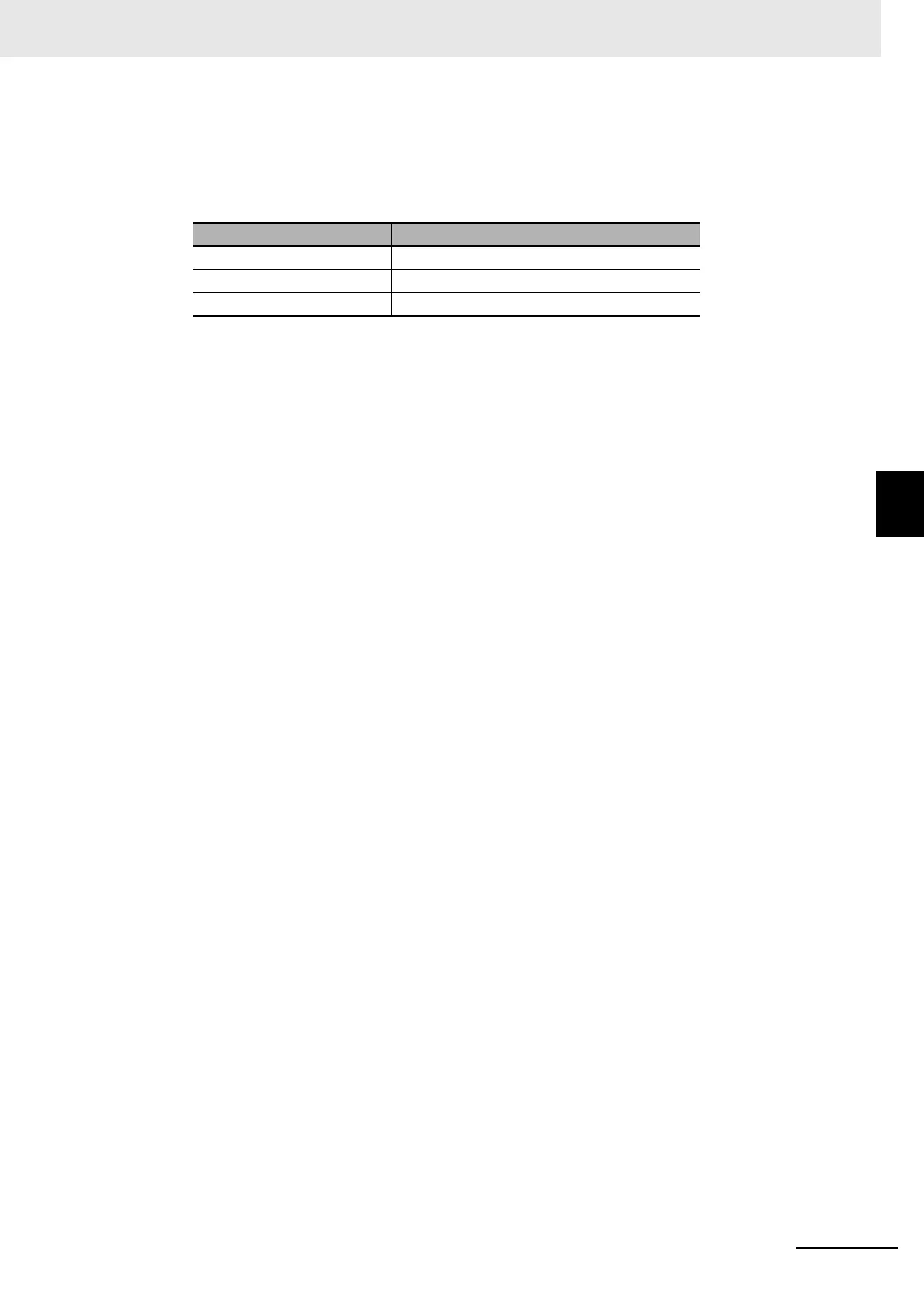

Motor Coil Unit model

Moving table (radiator plate) dimensions

R88L-EC-GW-03 254 × 120 × 12

R88L-EC-GW-05 330 × 120 × 12

R88L-EC-GW-07 460 × 180 × 12

Loading...

Loading...