Motion sequence and axes Section 1-8

23

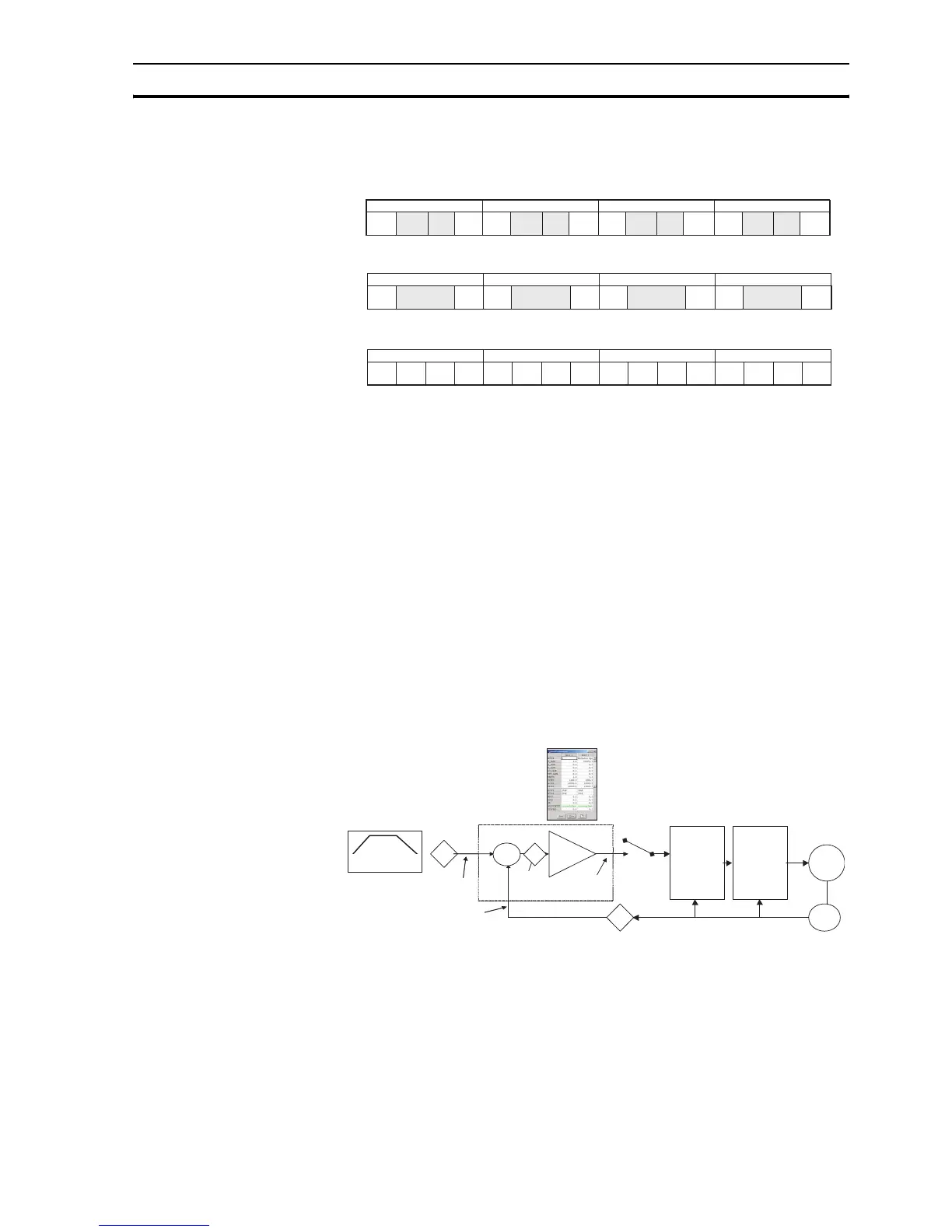

1-7-4 Multi-tasking example

In the example 1, there are two high-priority processes, 13 and 14. The two HT

periods are reserved for these processes, one for processes 13 and one for

processes 14. The low-priority processes 3, 2, 1 and 0 are executed in the LT

period, one process per Cycle time here set to 1.0ms.

In the middle example, there is only one high-priority process, 14. Both HT

periods are reserved for this process. The low-priority processes, 3, 2, 1 and 0

are executed in the LT period, one process per cycle time.

In the lower example, there are no high-priority processes. Therefore, the HT

periods can be used for the low-priority processes. The LT period is also used

for the low-priority processes.

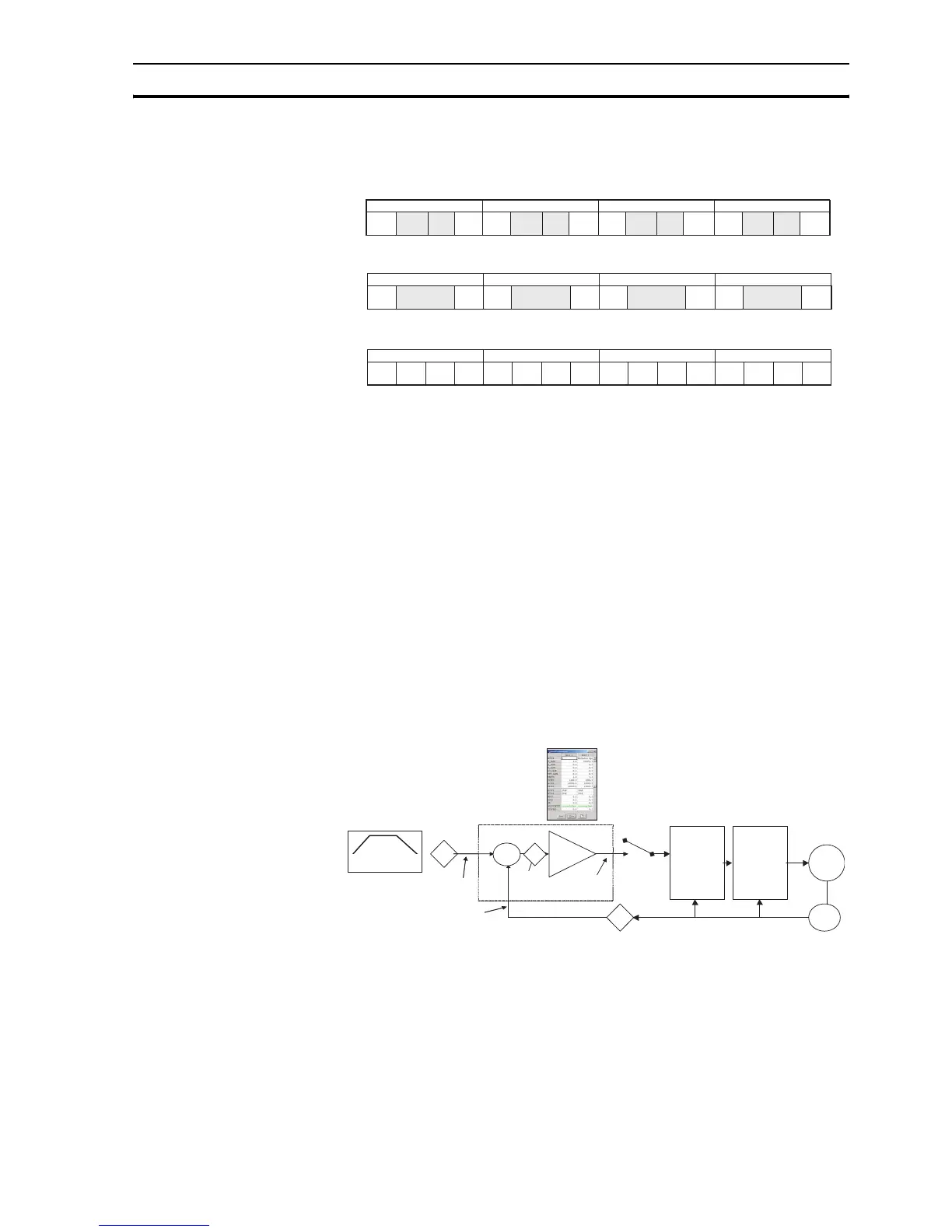

1-8 Motion sequence and axes

Motion sequence is the part of the CJ1W-MCH72 that controls the axes. The

actual way that the motion sequence operates depends on the axis type. The

axis type can be set and read by the parameter ATYPE. At start-up the

Trajexia system automatically detects the configuration of the axes.

• The default value for the parameter ATYPE for MECHATROLINK-II axes is

40 (MECHATROLINK-II position).

• The default value for the parameter ATYPE for the Encoder Interface is 44

(incremental encoder).

2

3

14

13

14

13

143

COMS.

1ms

142

COMS. COMS.

1ms

141

1ms

140

(c/l)

1ms

COMS.

321

COMS.

1ms

0

(c/l)

32

COMS. COMS.

1ms

10

(c/l)

3

COMS.

1ms

210

(c/l)

1ms

1

3

COMS.

1ms

2

COMS. COMS.

1ms

1

1ms

0

(c/l)

1ms

COMS.

14

13

14

13

• block

•

Profile generatorProfile generator

+

-

Position loop

Demanded

position

Measured

position

Following

error

Speed

command

+

-

Position loop

Demanded

position

Measured

position

Following

error

Speed

command

Speed loop

ON

OFF

Torq ue

loop

M

E

AXIS PARAMETER

Servo Drive

Loading...

Loading...