Ignition

and

Battery

Charging

I

G

N

IT1

0

N

SYSTEM

D

ESCRl PTI

ON

The engine is equipped with an automotive type battery

ignition system. Both spark plugs fire simultaneously,

thus

the need for

a

distributor

is

eliminated.

I

IGNITION

TIMING

Thetiming is preset at thefactory. Slight timing changes

can be made by adjusting the point gap.

BREAKER

POINTS

The timing is adjusted

to

specification during initial

engine assembly and is fixed by the point gap adjust-

ment.

To

maintain maximum engine efficiency, change

the breaker points as recommended in the Periodic

Maintenance Schedule.

Replacement and Adjustment

1.

Remove spark plugs.

2.

Remove breaker box cover. Rotatecrankshaftclock-

wise (facing flywheel) until points are fully open.

3.

Remove condenser (screw A) and detach condenser

lead and coil lead (screw

6).

Engines with con-

densers mounted on the air cleaner bracket

do

not

need

to

be removed unless being replaced.

4.

Remove two Allen screws (C) and lift breaker

assembly from engine.

5.

Replace condenser and point assembly with new

parts and reinstall using above procedure in reverse

order of removal.

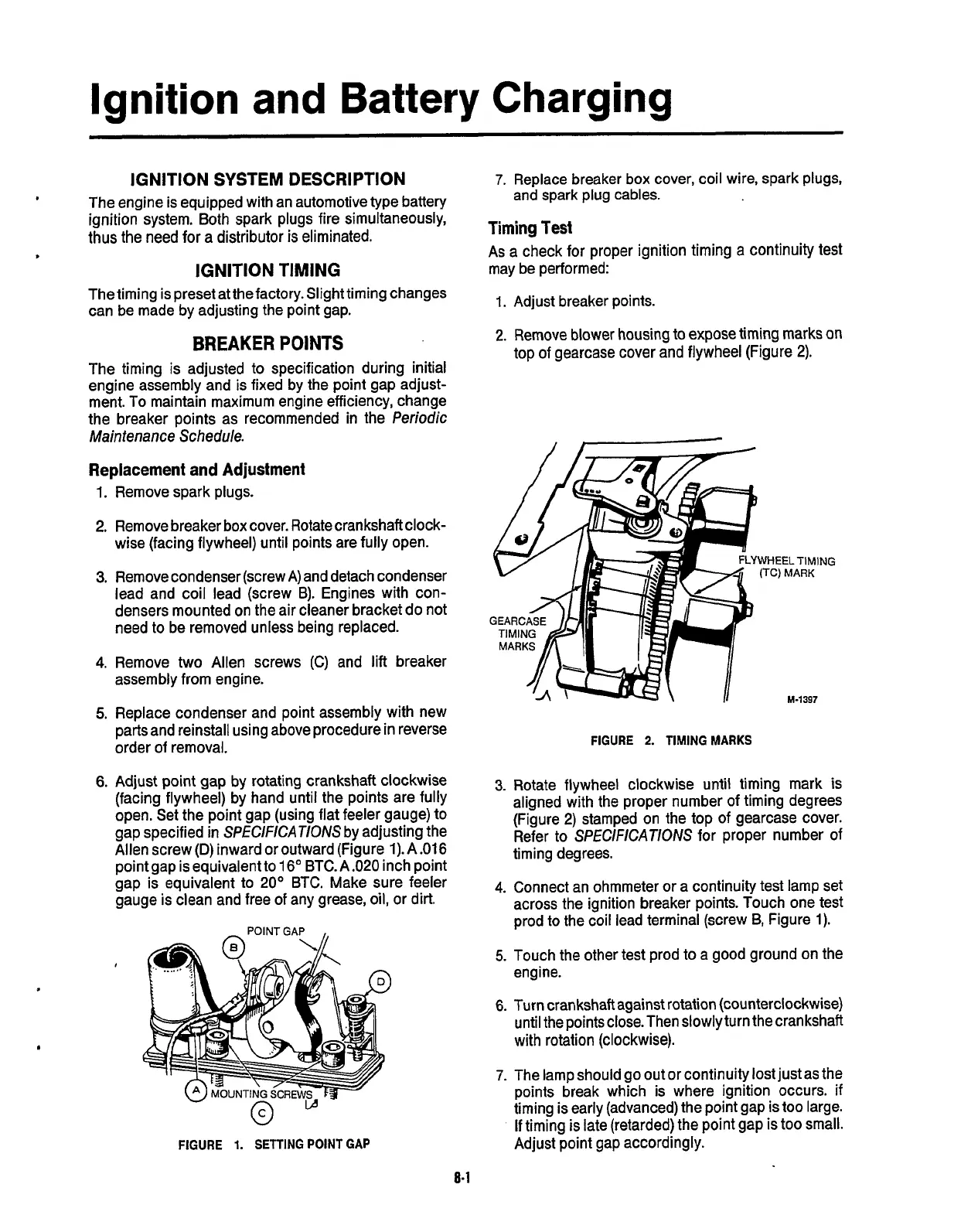

6.

Adjust point gap by rotating crankshaft clockwise

(facing flywheel) by hand until the points are fully

open. Set the point gap (using flat feeler gauge)

to

gap specified in

Sf€ClFlCATlONS

by adjusting the

Allen screw (D) inward or outward (Figure

1).

A.016

point gap is equivalent to 16" BTC.A.020 inch point

gap is equivalent to 20" BTC. Make sure feeler

gauge

is

clean and free

of

any grease, oil, or dirt.

POINTGAP

,.

W

FIGURE

1.

SETTING

POINT

GAP

7.

Replace breaker box cover, coil wire, spark plugs,

and spark plug cables.

Timing Test

As a check for proper ignition timing

a

continuity test

may be performed:

1.

Adjust breaker points.

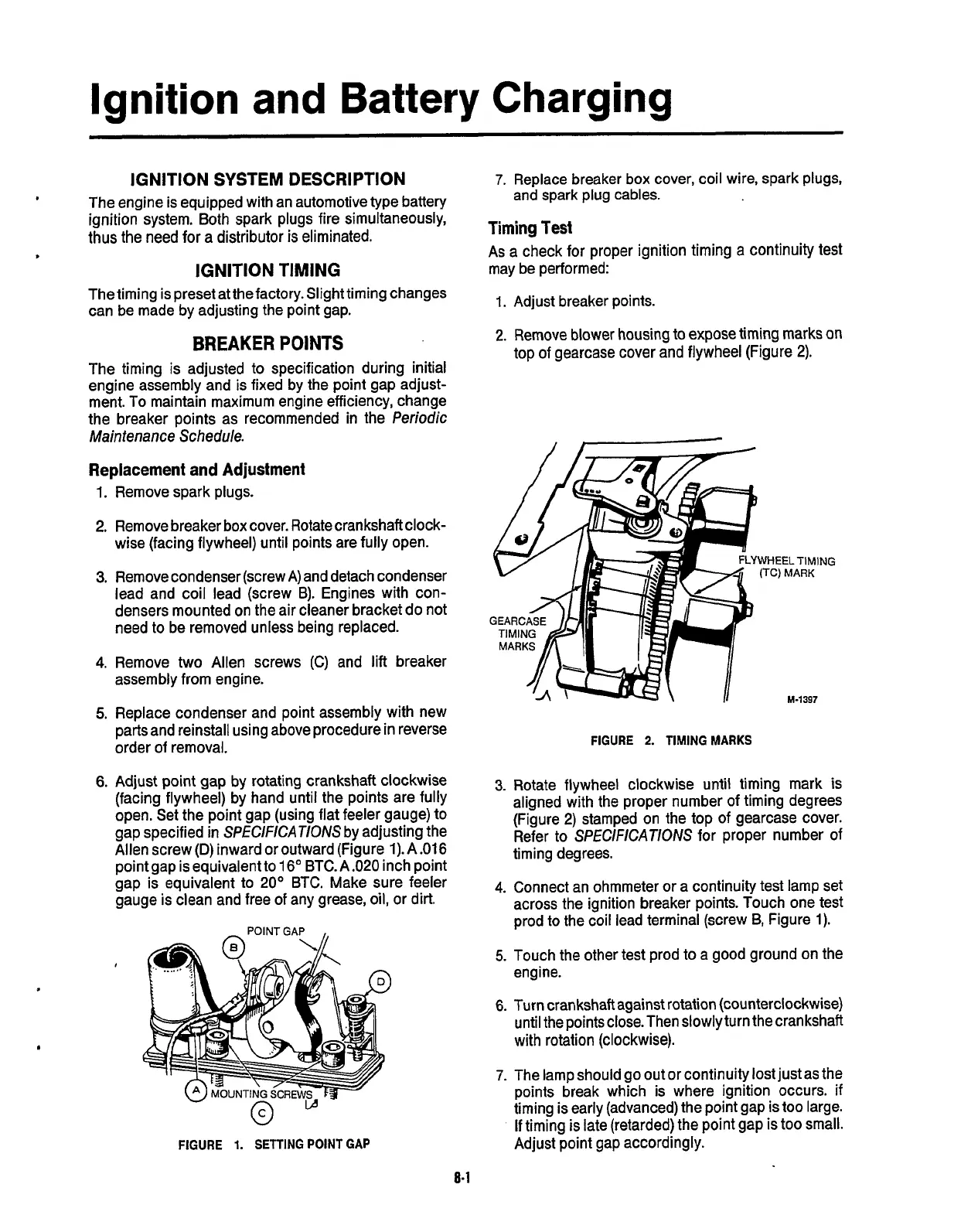

2.

Remove blower housing

to

expose timing marks on

top

of

gearcase cover and flywheel (Figure

2).

YWHEELTIMING

(TC)

MARK

M-1397

FIGURE

2.

TIMING

MARKS

3.

Rotate flywheel clockwise until timing mark

is

aligned with the proper number of timing degrees

(Figure

2)

stamped on the top of gearcase cover.

Refer to

SPEClFlCATlONS

for proper number

of

timing degrees.

4.

Connect an ohmmeter or a continuity test lamp set

across the ignition breaker points. Touch one test

prod to the coil lead terminal (screw

B,

Figure

1).

5.

Touch the other test prod to a good ground on the

engine.

6.

Turn crankshaft against rotation (counterclockwise)

until the points close. Then slowly turn the crankshaft

with rotation (clockwise).

7.

The lamp should go out or continuity lost just as the

points break which is where ignition occurs.

if

timing is early (advanced) the point gap is

too

large.

If

timing is late (retarded) the point gap is

too

small.

Adjust point gap accordingly.

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...