2.

Assemble brushes

so

that the chamfered side is

away from the brush springs. Make sure brush

wires

do

not rub against the commutator or end cap.

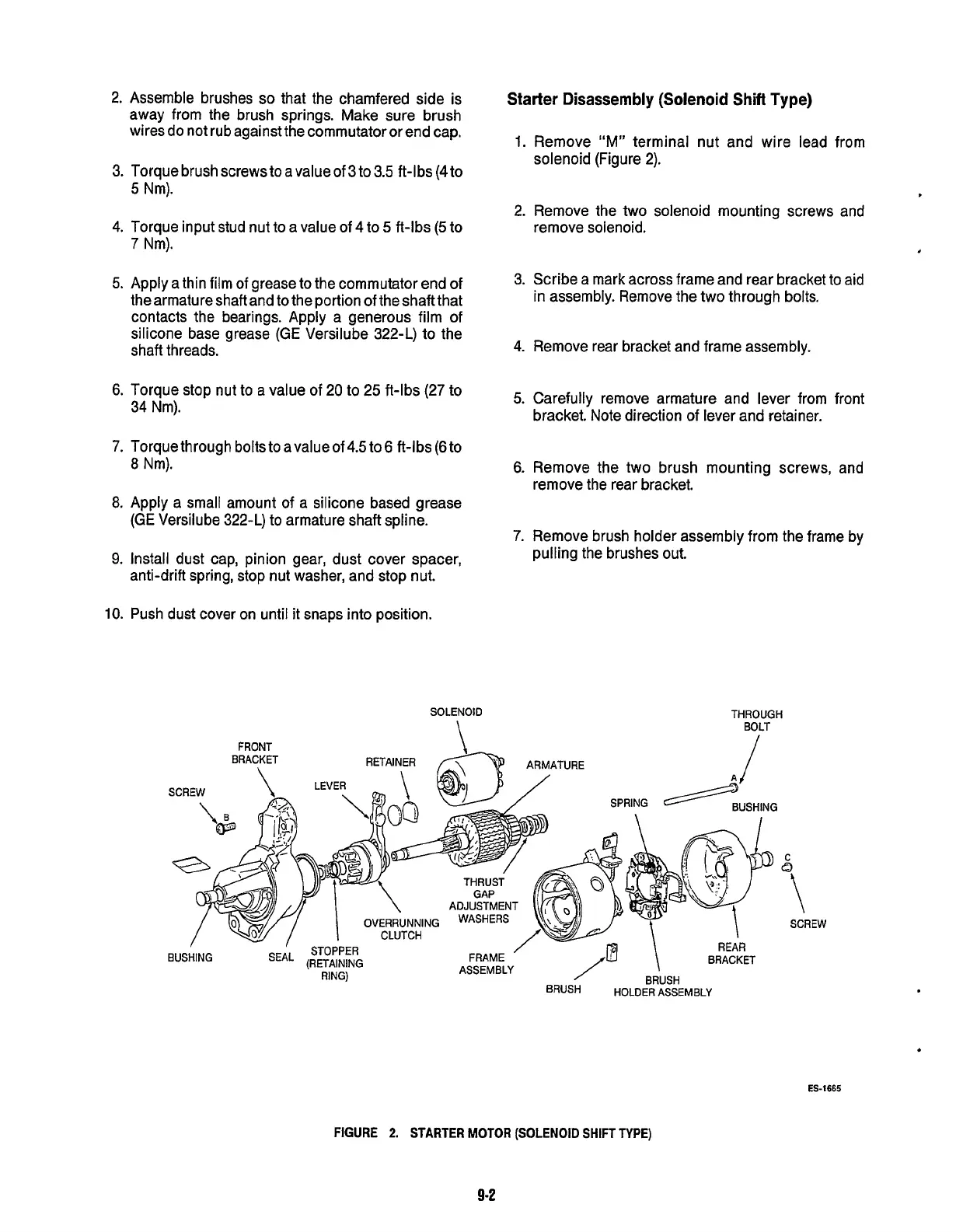

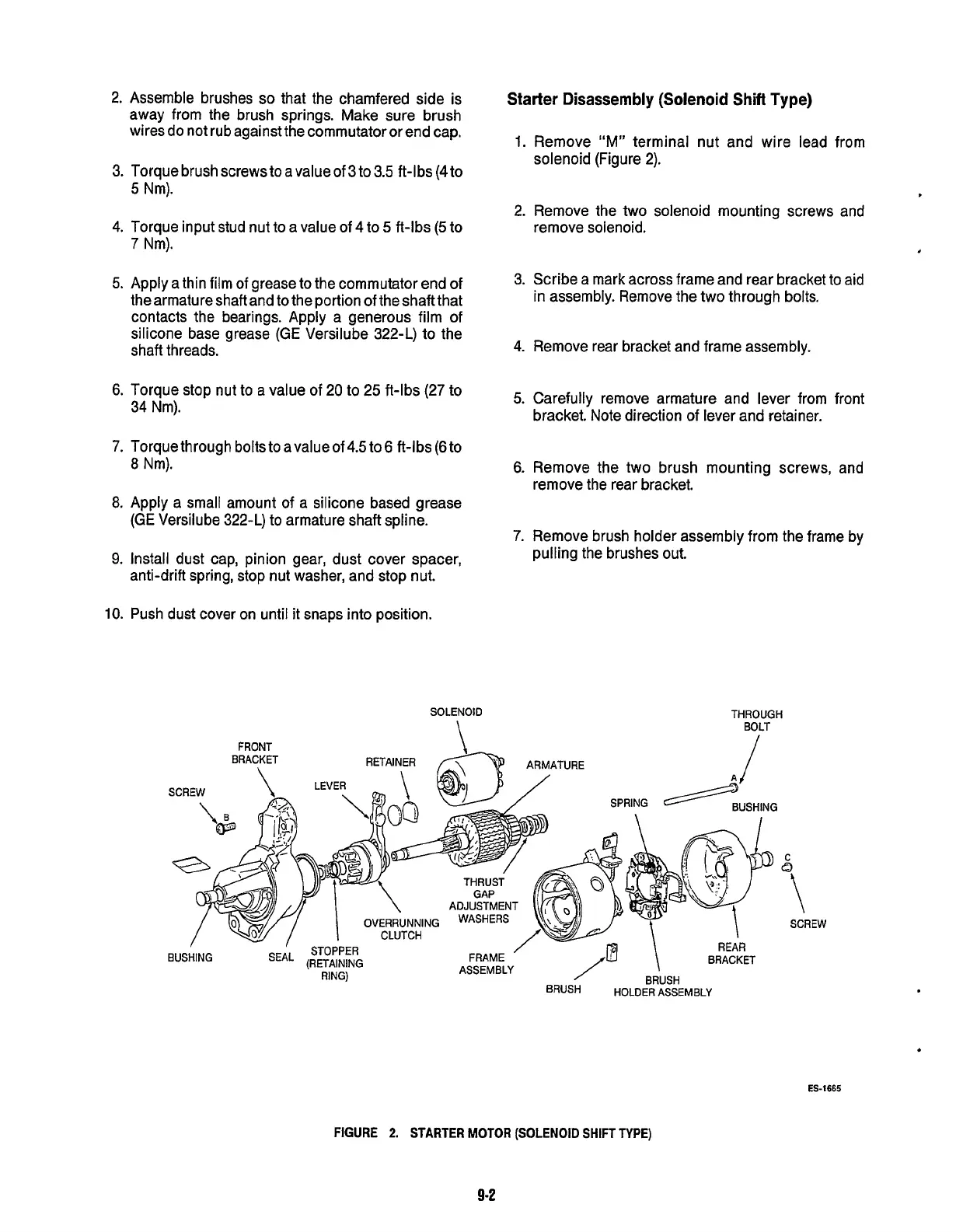

Starter

Disassembly (Solenoid

Shifl

Type)

1.

Remove "M" terminal nut and wire lead from

solenoid (Figure 2).

3. Torque brush screws to a value

of

3

to

3.5 ft-lbs

(4tO

5

Nm).

2. Remove the

two

solenoid mounting screws and

remove solenoid.

4.

Torque input stud nut

to

a value of 4 to

5

ft-lbs

(5

to

7

Nm).

3. Scribe a mark across frame and rear bracket to aid

in assembly. Remove the two through bolts.

5.

Apply a thin film of grease to the commutator end of

the armature shaft and

to

the portion of the shaft that

contacts the bearings. Apply a generous film of

silicone base grease

(GE

Versilube 322-L) to the

shaft threads.

4.

Remove rear bracket and frame assembly.

6.

Torque stop nut

to

a

value of 20

to

25

ft-lbs

(27

to

34 Nm).

5.

Carefully remove armature and lever from front

bracket. Note direction of lever and retainer.

7.

Torque through bolts to avalueof

4.5

to

6

ft-lbs

(6

to

8

Nm).

6.

Remove the two brush mounting screws, and

remove the rear bracket.

8.

Apply a small amount of a silicone based grease

(GE

Versilube 322-L) to armature shaft spline.

7.

Remove brush holder assembly from the frame by

pulling the brushes out.

9.

Install dust cap, pinion gear, dust cover spacer,

anti-drift spring, stop nut washer, and stop nut.

10.

Push dust cover on until

it

snaps into position.

SOLENOID

\

THROUGH

BOLT

FRONT

/

BRACKET

RETAINFR

SCREW

\

LEVEF

mn

C

I

\

GAP

OVERRUNNING

WASHERS

CLUTCH

.nn"T"

-.

..

\

ADJUSTMENT

SCREW

\

RFAR

C.T

.

.

-.

..

.

BRACKET

FRAME

ASSEMBLY

31

urrcn

RING)

SEAL

(RETAINING

BUSHING

BRUSH

HOLDER

ASSEMBLY

ES-1665

FIGURE

2.

STARTER MOTOR

(SOLENOID

SHIFT TYPE)

9-2

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...