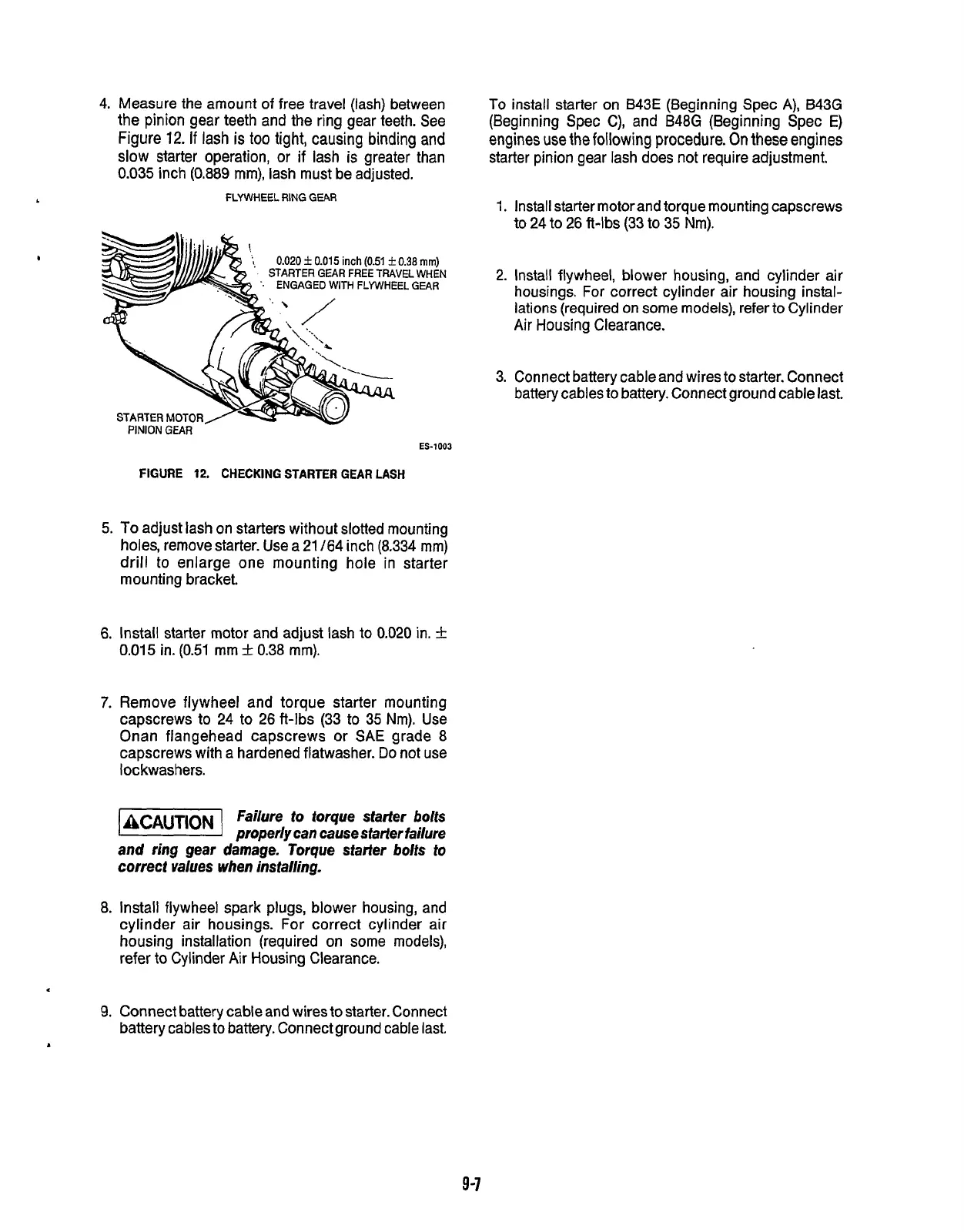

4. Measure the amount

of

free travel (lash) between

the pinion gear teeth and the ring gear teeth. See

Figure

12.

If

lash

is

too

tight, causing binding

and

slow starter operation, or if lash is greater than

0.035

inch (0.889 mm), lash must be adjusted.

FLYWHEEL

RING

GEAR

STARTER

GEAR

FREE

TRAVEL WHEN

STARTER MOTOR

-

PINION

GEAR

ES-1003

FIGURE

12.

CHECKING

STARTER

GEAR

LASH

5.

To

adjust lash on starters without slotted mounting

holes, remove starter. Use a

21

164

inch (8.334 mm)

drill to enlarge one mounting hole in starter

mounting bracket.

6.

Install starter motor and adjust lash to 0.020 in.

3.

0.015

in.

(0.51

mm

k

0.38 mm).

7.

Remove flywheel and torque starter mounting

capscrews to 24 to

26

ft-lbs (33 to 35 Nm). Use

Onan flangehead capscrews or

SAE

grade

8

capscrews with a hardened flatwasher.

Do

not use

lockwashers.

-1

Failure

io

torque starter bolts

properly can

cause

starter failure

and ring gear

damage.

-Torque starter bolts to

correct values when installing.

8.

Install flywheel spark plugs, blower housing, and

cylinder air housings. For correct cylinder air

housing installation (required on some models),

refer

to

Cylinder Air Housing Clearance.

To

install starter on B43E (Beginning Spec A), B43G

(Beginning Spec

C),

and B48G (Beginning Spec

E)

engines

use

the following procedure.

On

these engines

starter pinion gear lash does not require adjustment.

1.

Install starter motor and torque mounting capscrews

to 24

to

26

ft-lbs

(33

to 35 Nm).

2.

Install flywheel, blower housing, and cylinder air

housings. For correct cylinder air housing instal-

lations (required on some models), refer to Cylinder

Air Housing Clearance.

3. Connect battery cable and wires to starter. Connect

battery cables

to

battery. Connect ground cable last.

9.

Connect battery cable and wiresto starter. Connect

battery cables to battery. Connect ground cable last.

.

9-1

Redistribution or publication of this document,

by any means, is strictly prohibited.

Loading...

Loading...