Section

5.

Cooling

System

GENERAL

Throughout this manual, flotation water drawn into the

boat for engine cooling iscalled sea water. Water recircu-

lated through the engine closed system is called captive

water. Thus, confusion is avoided with other generic

terms describing water use.

The

two

types of marine cooling systems covered in this

manual are

heat exchanger

and

sea wafer

cooling. An

explanation

of

each system, and the advantages and

disadvantages of each are covered in separate chapter

headings. The heat exchanger system is ordered most

often and is standard on the

MCE

generator set Sea

water cooling is an available option.

System

Plumbing

To adequately cool the generator set under all conditions,

the plumbing system must be properly planned and

installed. Excess lengths of plumbing increases flow

resistance and results in reduced cooling. An air leak in

the sea water intake will reduce cooling, cause corrosion,

and can even destroy the neoprene impeller in the

sea

water pump. The neoprene impeller must never be run

dry, and should be primed before initial start

The water line should have a minimum inside diameter of

0.75

inch

(1

9

mm). For runs over

20

feet

(5.2

m), increase

the line one pipe size for each additional

10

feet

(2.6

m) of

length. Water lines can be either copper tubing or flexible

hose. Be sure a length of flexible hose is used at the

generator set connection to allow set movement and for

noise abatement

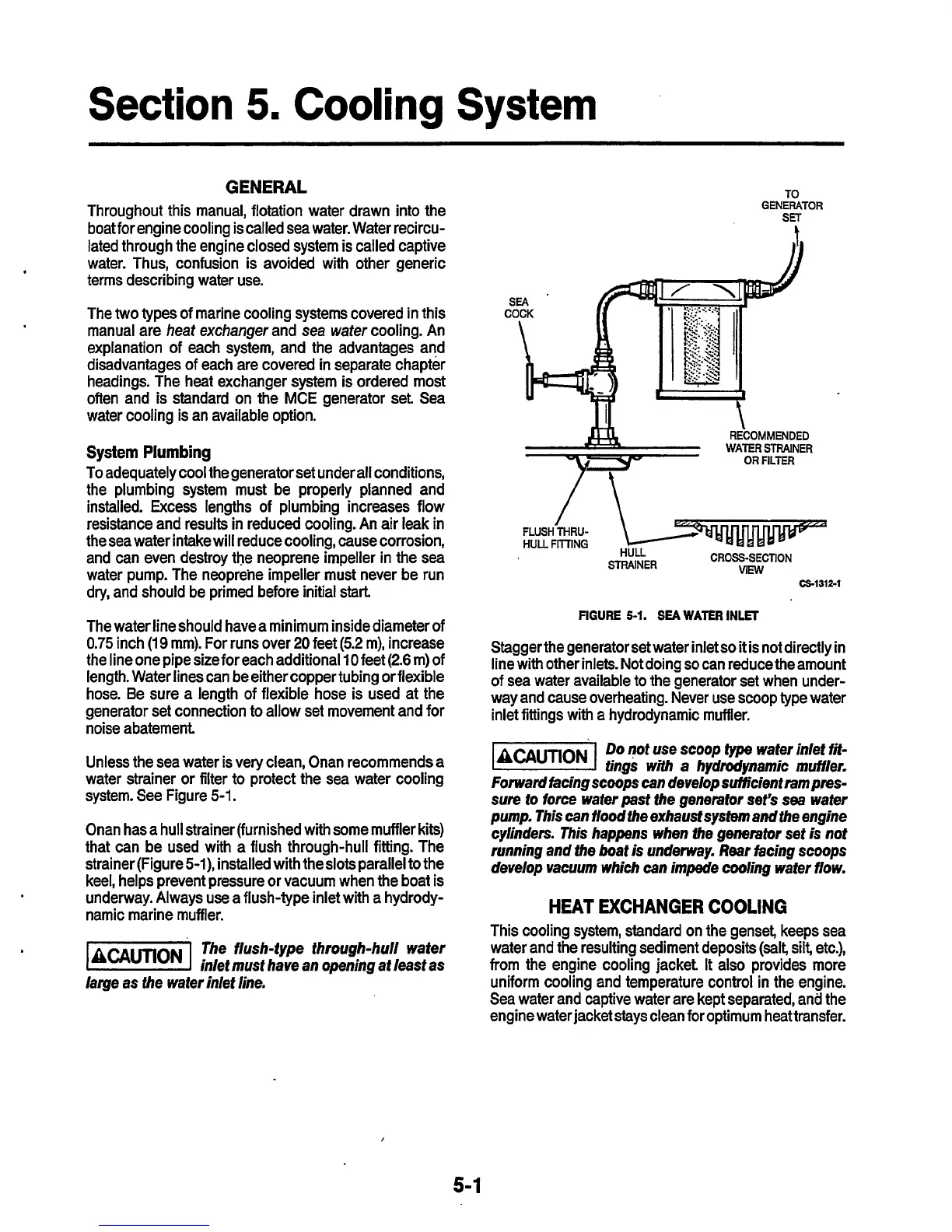

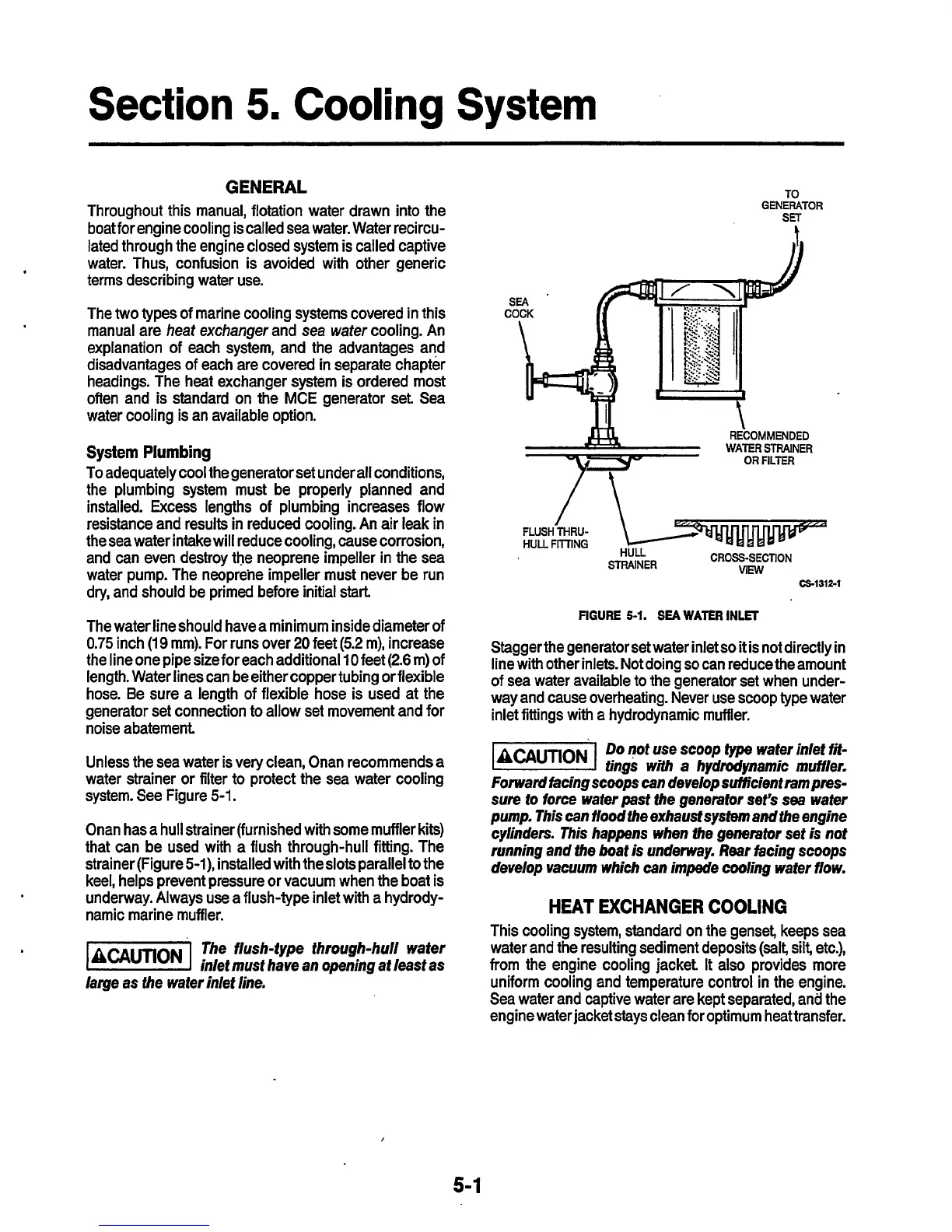

Unless the sea water is very clean, Onan recommends a

water strainer or filter to protect the sea water cooling

system. See Figure

5-1.

Onan has a hull strainer (furnished with some muffler kits)

that can be used with a flush through-hull fitting. The

strainer (Figure

!SI),

installed with theslots parallel to the

keel, helps prevent pressure or vacuum when the boat is

underway. Always use a flush-type inlet with a hydrody-

namic marine muffler.

The flush-fype through-hull wafer

inlef must have

an

opening at least as

lame as fhe wafer inlef line.

TO

GENERATOR

SET

RECOMMENDED

WATER

STRAINER

OR

FILTER

FLUSH

THRU-

HULL

FllllNG

STF

CROSS-SECTION

VlMl

HULL.

--WNER

CS-1312-1

FIGURE

5-1.

SEA

WATER

INLET

Stagger the generator set water inlet

so

it is not directly in

line with other inlets. Not doing

so

can reduce the amount

of sea water available to the generator set when under-

way and cause overheating. Never use scoop type water

inlet fittings with a hydrodynamic muffler.

-1

Do

not use scoop

fype

wafer inlet

fit-

tings with

a

hydrodynamic muifler.

Forward

facing

scoops can develop suiiicienf

rampres-

sure

to force wafer

past

the

generator

sefs

sea

wafer

pump. This can floodfhe exhausfsystemandfhe engine

cylinders. This

happens

when the generator set

is

not

running and the boat

is

underway.

Rear

iacing scoops

develop vacuum which can impede

ding

wafer flow.

HEAT EXCHANGER COOLING

This cooling system, standard on the genset, keeps sea

water and the resulting sediment deposits

(salt,

silt, etc.),

from the engine cooling jacket It also provides more

uniform cooling and temperature control in the engine.

Sea water and captive water are kept separated, and the

engine water jacket stays clean for optimum heat transfer.

5-1

Loading...

Loading...