Exhaust

Cooling

Water

Injection

The neoprene impeller pump moves the

sea

water

through the

cooling

system and into the exhaust manifold.

The injected water cools the exhaust and prevents

exhaust system damage from heat

A

temperature oper-

ated switch on theexhaust manifold shu tsthe unit down if

overheating occurs. The switch closes if temperature

reaches

175'

to

185°F

(79'

to

85'C)

and actuates the

Fault Reset breaker on the control panel.

If

high exhaust

temperature shutdown occurs, the entire exhaust system

should be checked for any signs

of

overheating, espe-

cially the exhaust hoses. Replace defective components

immediately, and do not operate the generator set until

Inhalation of exhaust gas

can

cause

jawnR"Gl

severe personal

injury

or

death.

Do

not operate the generator set after a high exhaust

temperature shufdown until the entire exhaust system

has been checked

and

serviced as mquimd.

.

system is repaired.

DO

NOT

USE

SCOOP

TYPE

WATER

-1

INLET FITTINGS. Forward

facing

scoops

can

develop suificient ram

pressure

to

torce

wafer

past

the

generator set's

sea

waferpump. Thiscan

flood

the

exhaust system and the engine cylinders. This

happens when the generafor set

is

not running and the

boat

is

underway. Rear facing scoops develop vacuum

which

can

impede

cooling

water flow.

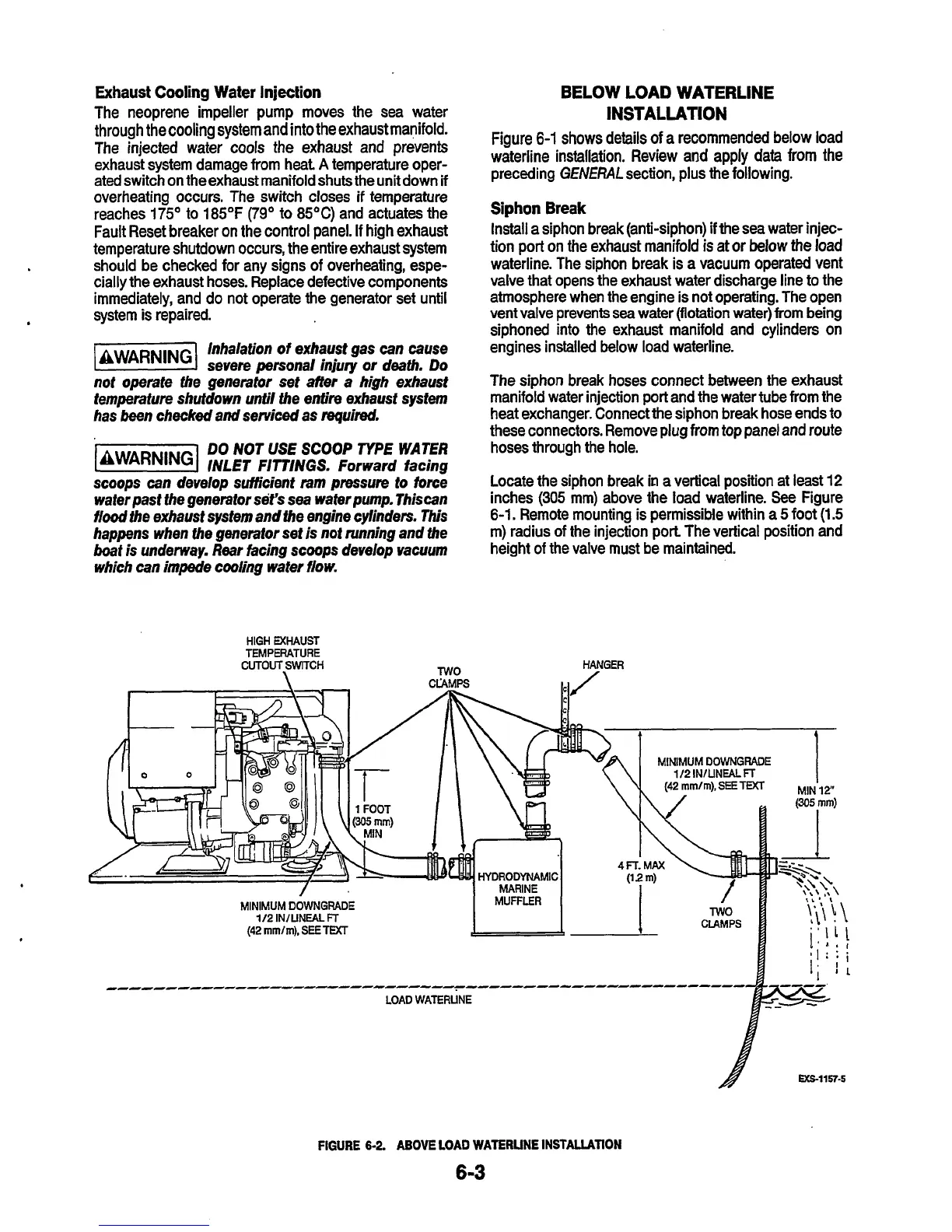

BELOW

LOAD

WATERLINE

INSTALLATION

Figure

6-1

shows details

of

a

recommended below load

waterline installation. Review and apply

data

from

the

preceding

G€N€ML

section, plus the following.

Siphon

Break

Install a siphon break (anti-siphon)

if

the

sea

water injec-

tion port on

the

exhaust manifold

is

at or below

the

load

waterline. The siphon break is a vacuum operated vent

valve that opens the exhaust water discharge line to the

atmosphere when the engine

is

not operating. The open

vent valve prevents

sea

water (flotation water) from being

siphoned into the exhaust manifold and cylinders on

engines installed below load waterline.

The siphon break hoses connect between the exhaust

manifold water injection port and the water tube from the

heat exchanger. Connect the siphon break hose ends to

these connectors. Remove plug from top panel and route

hoses through the hole.

Locate the siphon break in a vertical position at least

12

inches

(305

mm) above the load waterline.

See

Figure

6-1.

Remote mounting is permissible within a

5

foot

(1.5

m) radius

of

the injection port The vertical position and

height of the valve must be maintained.

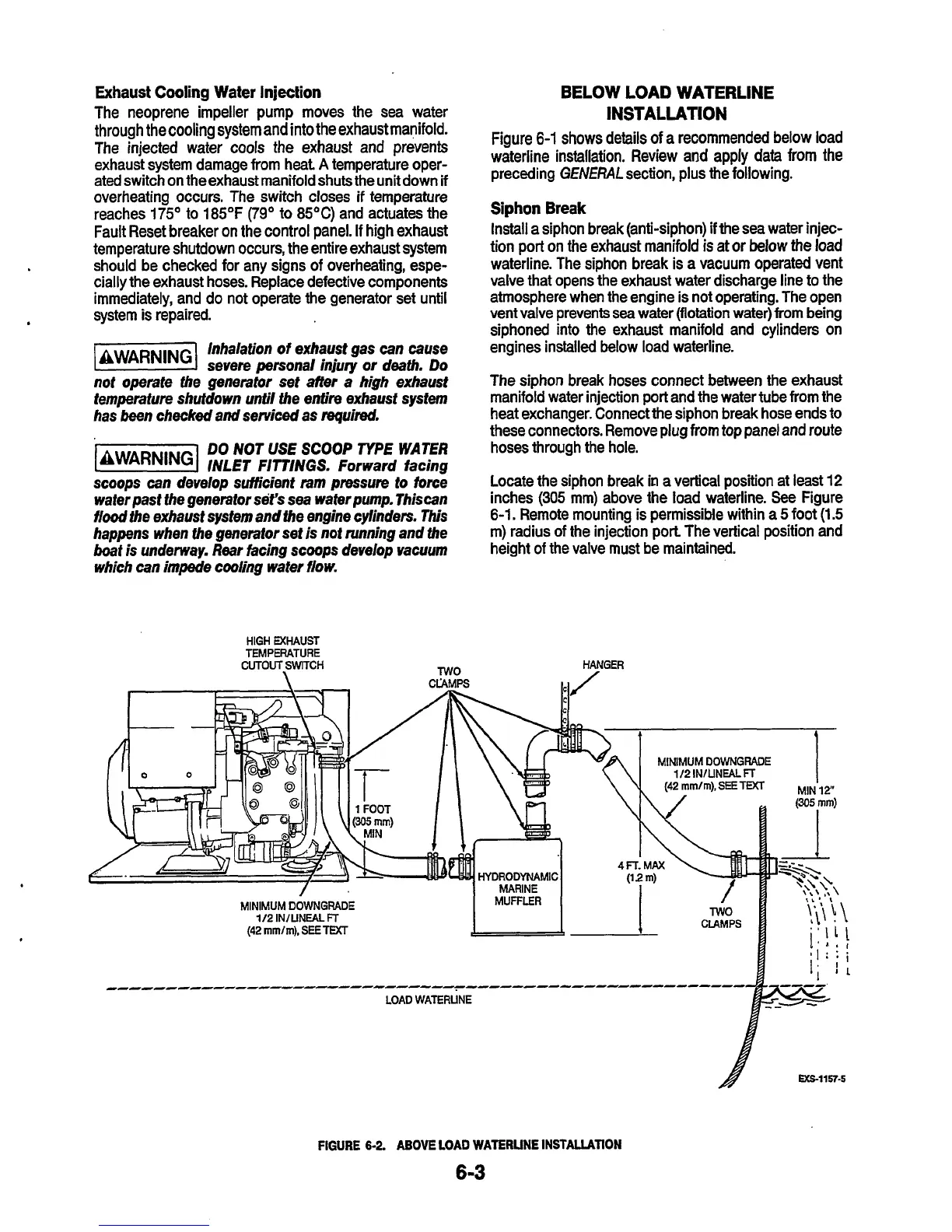

HIGH EXHAUST

TEMPERATURE

CUTOUT,SWITCH

TWO

HANGER

MINIMUM

DOWNGRADE

112

INlLlNEAL

FT

-------------------------------------------------------

LOAD WATERLINE

FIGURE

6-2.

ABOVE

LOAD

WATERLINE

INSTALIATION

6-3

Loading...

Loading...