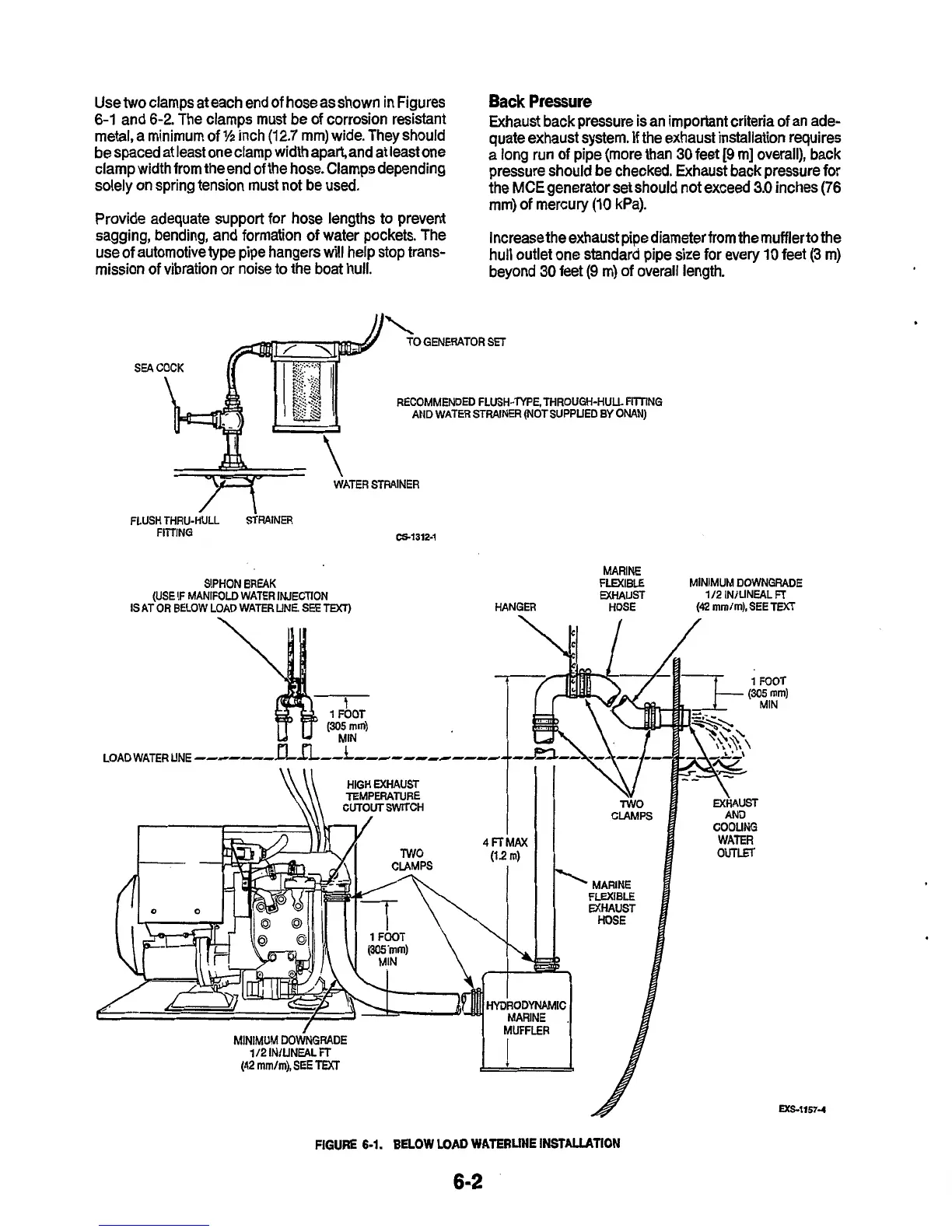

Usetwo clamps at each end of hoseasshown in Figures

6-1

and

6-2.

The clamps must be

Of

corrosion resistant

metal, a minimum Of% inch

(12.7

mm) wide. They should

be spaced at kist one clamp width apart, and at least one

clamp widthfromtheend ofthe hose. Clamps depending

solely on spring tension must not be used.

Provide adequate support for hose lengths to prevent

sagging, bending, and fOrmation

Of

water Pockets- The

use ofautomotive@Pe Pipe hangers

Will

help stop tms-

mission of vibration or noise to the boat hull.

Back

Pressure

Exhaust back pressure is an important criteria of an a&-

quate exhaust system.

If

the exhaust installation requires

a long run of pipe (more than

30

feet

[9

m] overall), back

pressure should be checked. Exhaust back pressure for

the

MCE

generator set should not exceed

3.0

inches (76

rnm) of mercury

(10

kPa).

Increase theexhaust pipe diameter from the mufflertothe

hull outlet one standard pipe size for every

10

feet

(3

m)

beyond

30

feet

(9

m) of overall length.

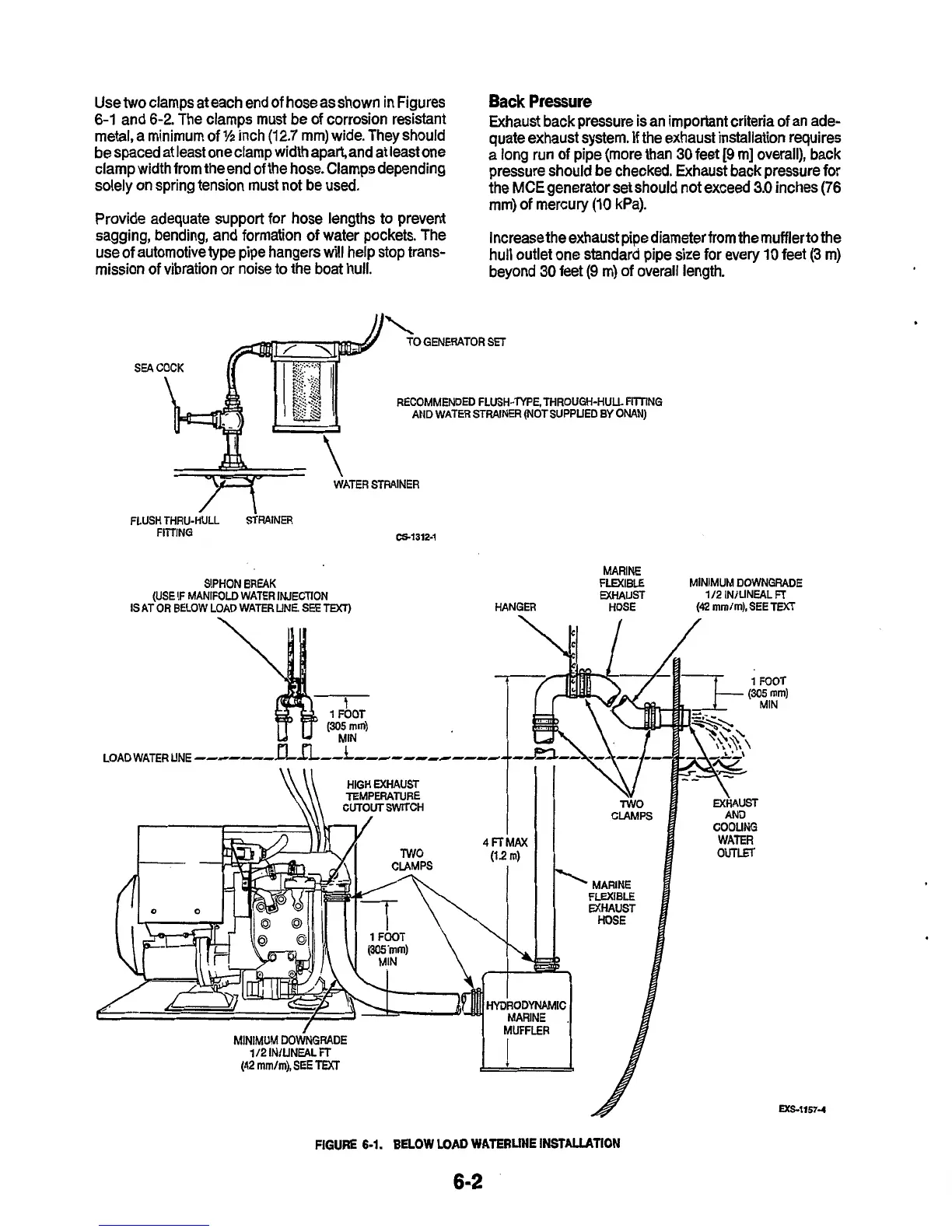

"\

TO GENERATOR

SET

SEA

c

RECOMMENDED FLUSH-TYPE, THROUGH-HULL FliTlNG

AND WATER STRAlNER (NOTSUPPUED

BY

ONAN)

.

FLUSH THRU-HULL Sk/VNER

CS-1312-1

FllTING

FIGURE

6-1.

BELOW

LOAD

WATERLINE

INSTAWTlON

6-2

Loading...

Loading...