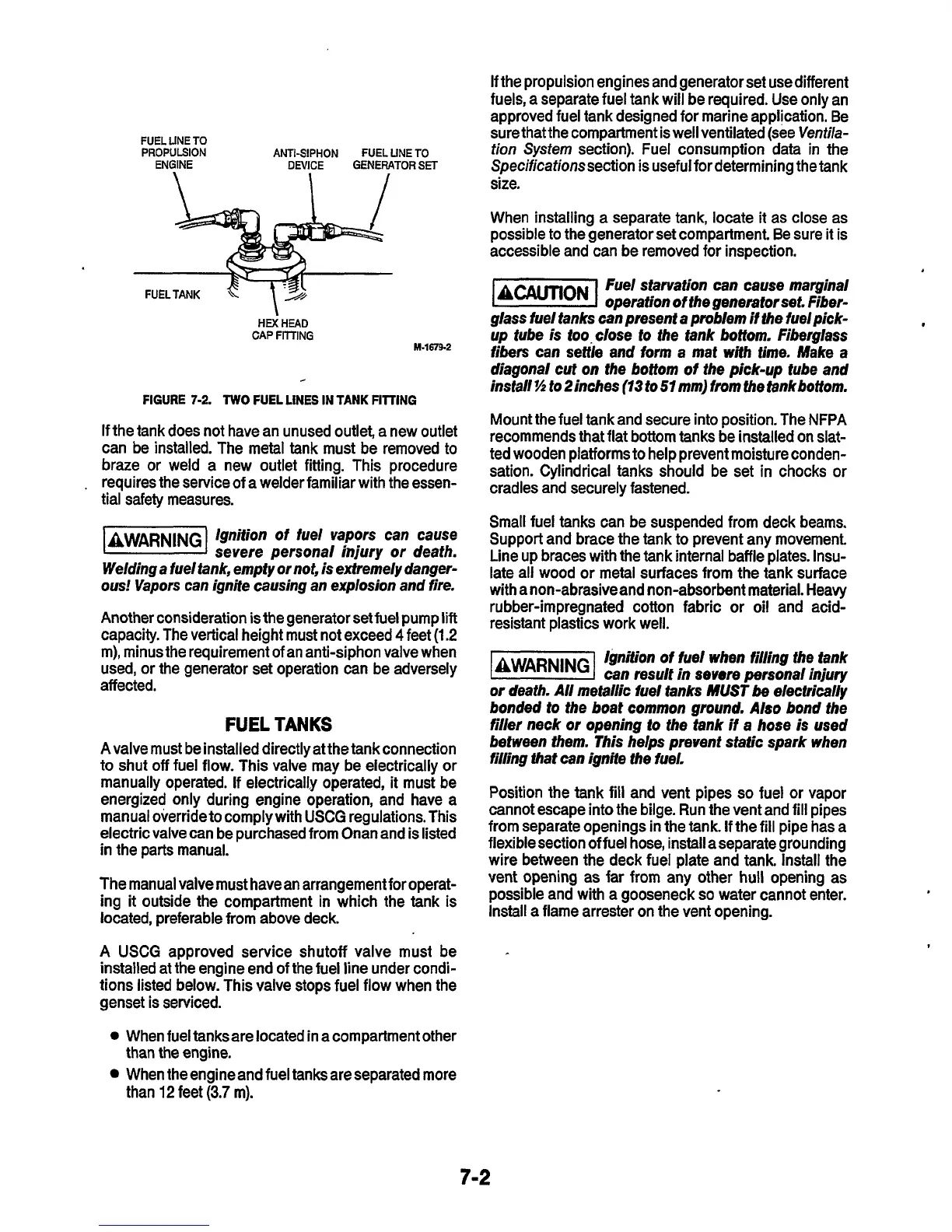

FUEL LINE TO

PROPULSION ANTI-SIPHON FUEL UNE TO

ENGINE DEVICE GENERATOR

SET

HEX

HEAD

CAP

FTTTING

FIGURE

7-2.

TWO

FUEL LINES IN

TANK

FllllNG

1-1679.2

If

the tank does not have an unused outlet, a new outlet

can be installed. The metal tank must be removed to

braze

or

weld a new outlet fitting. This procedure

.

requires the service of a welder familiar with the essen-

tial safety measures.

1-1

Ignition

of

fuel vapors can cause

severe personal injury

or

death.

Welding a

fuel

tank, empty

or

not, is extremely danger-

ous!

Vapors can ignite causing an explosion and fire.

Another consideration is the generator set fuel pump

lift

capacity. The vertical height must not exceed

4

feet

(1.2

m), minus the requirement

of

an anti-siphon valve when

used,

or

the generator set operation can be adversely

affected.

FUEL

TANKS

Avalve must be installed directly at the tank connection

to shut

off

fuel flow. This valve may be electrically

or

manually operated. If electrical1,y operated, it must be

energized only during engine operation, and have a

manual override to comply with

USCG

regulations. This

electric valve can be purchased from Onan and is listed

in the parts manual.

The manual valve must have an arrangement for operat-

ing

it

outside the compartment in which the tank is

located, preferable from above deck.

A USCG approved service shutoff valve must be

installed at the engine end of the fuel line under condi-

tions listed below. This valve stops fuel flow when the

genset is serviced.

0

When fueltanksare located in a compartment other

When the engine and fuel tanks are separated more

than the engine.

than

12

feet

(3.7

m).

If the propulsion engines and generator set usedifferent

fuels, a separate fuel tank will be required. Use only an

approved fuel tank designed

for

marine application. Be

sure thatthe Compartment is well ventilated (see

Ventila-

tion

System

section). Fuel consumption data in the

Specificafionssection is useful for determining the tank

size.

When installing a separate tank, locate it as close as

possible to the generator set Compartment. Be sure it is

accessible and can be removed for inspection.

Fuel starvation can cause marginal

operation of the generator

set.

Fiber-

glass

fuel

tanks can present a problem if the fuel pick-

up tube is too.close

to

the tank bottom. Fiberglass

fibers can seftle and

form

a

mat

wifh

time.

Make

a

diagonal cut

on

the bottom

of

the pick-up tube and

install

35

to Pinches

(73

to

51

mm) from the fankbottom.

Mount the fuel tank and secure into position. The

NFPA

recommends that flat bottom tanks be installed on slat-

ted wooden platforms to help prevent moisture conden-

sation. Cylindrical tanks should be set in chocks

or

cradles and securely fastened.

Small fuel tanks can be suspended from deck beams.

Support and brace the tank to prevent any movement.

Line up braces with the tank internal baffle plates. Insu-

late all wood

or

metal surfaces from the tank surface

with a non-abrasiveand nonabsorbent material. Heavy

rubber-impregnated cotton fabric or oil and acid-

resistant plastics work well.

Ignition of fuel

when

filling the tank

l&lZ@l

can result in

seuere

personal injury

or

death. All metallic fuel tanks

MUST

be

electrically

bonded to

the

boat common ground. Also bond the

filler neck

or

opening

to

the tank if a hose is used

between them. This helps prevent static spark when

filling that can ignite the fuel.

Position the tank

fill

and vent pipes

so

fuel

or

vapor

cannot escape into the bilge. Run the vent and

fill

pipes

from separate openings in the tank.

If

the

fill

pipe has a

flexible section of fuel hose, install aseparate grounding

wire between the deck fuel plate and tank. Install the

vent opening as far from any other hull opening as

possible and with a gooseneck

so

water cannot enter.

Install a flame arrester on the vent opening.

7-2

Loading...

Loading...