The purpose of the engine governor is to maintain a

constant engine speed during changes in power

demands.

A

governor responds to changes in power

demands by varying the throttle position.

A

constant-

speed governor is standard on industrial engines.

GOVERNORS

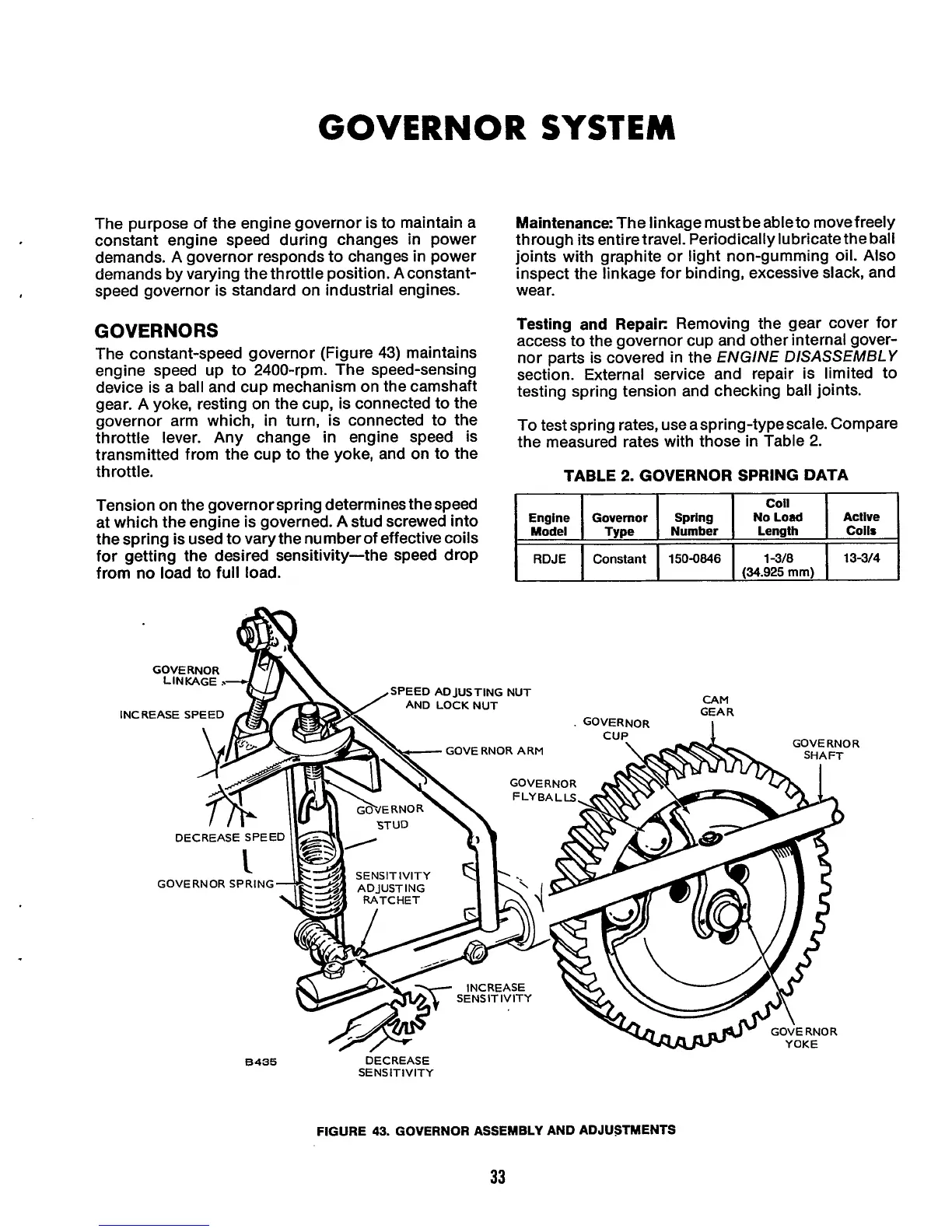

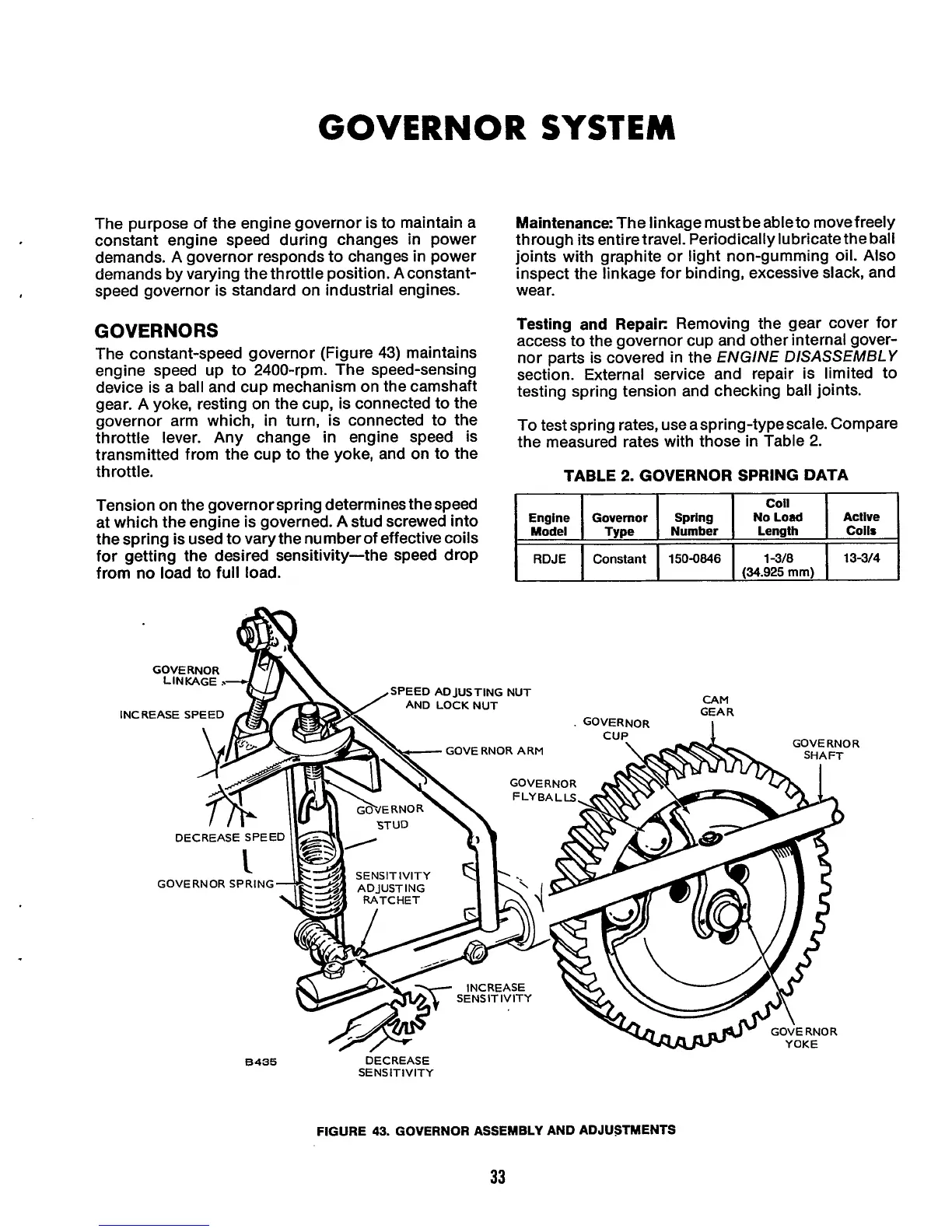

The constant-speed governor (Figure

43)

maintains

engine speed up to 2400-rpm. The speed-sensing

device is a ball and cup mechanism on the camshaft

gear.

A

yoke, resting on the cup, is connected to the

governor arm which, in turn, is connected to the

throttle lever. Any change in engine speed is

transmitted from the cup to the yoke, and on to the

throttle.

Maintenance:

The linkage must

be

ableto move freely

through its entiretravel. Periodically lubricate

the

ball

joints with graphite or light non-gumming

oil.

Also

inspect the linkage for binding, excessive slack, and

wear.

Testing and Repaie

Removing the gear cover for

access to the governor cup and other internal gover-

nor parts is covered in the

ENGINE DISASSEMBLY

section. External service and repair is limited to

testing spring tension and checking ball joints.

To

test spring rates, use aspring-type scale. Compare

the measured rates with those

in

Table 2.

TABLE 2. GOVERNOR SPRING DATA

Tension on the governor spring determines the speed

at which the engine is governed. A stud screwed into

the spring is used to vary the number of effective coils

for getting the desired sensitivity-the speed drop

from

no

load to full load.

Engine Governor Spring No

Load

Active

Constant

150-0846

1-3f8

13-m

1

;:

1

Type

1

Number

I

Length

I

Coils

I

(34.925

mm)

8435

DECREASE

SENSITIVITY

FIGURE

43.

GOVERNOR ASSEMBLY AND ADJUSTMENTS

33

Loading...

Loading...