STARTING

SYSTEM

These models use a separate

12

volt starting motor

mounted on the right hand side of the engine to drive

the flywheel.

It

is a standard automotive starting

motor with a solenoid for engaging the pinion and an

over-running clutch. When the solenoid is energized,

its core pulls in, shifting the pinion into engagement

with the flywheel

ring gear. At

the

same time,

contacts in the solenoid close to provide a circuit for

the starter motor. The starting motor remains engaged

until the starting switch is released.

If

engine

is

equipped with a start-disconnect switch, the starter

motor will automatically disengage flywheel gear when engine

speed reaches about

900

rpm.

The starter is protected from over-speed

by

an over-

running clutch which permits the engine to run faster

then the starter before the pinion is disengaged.

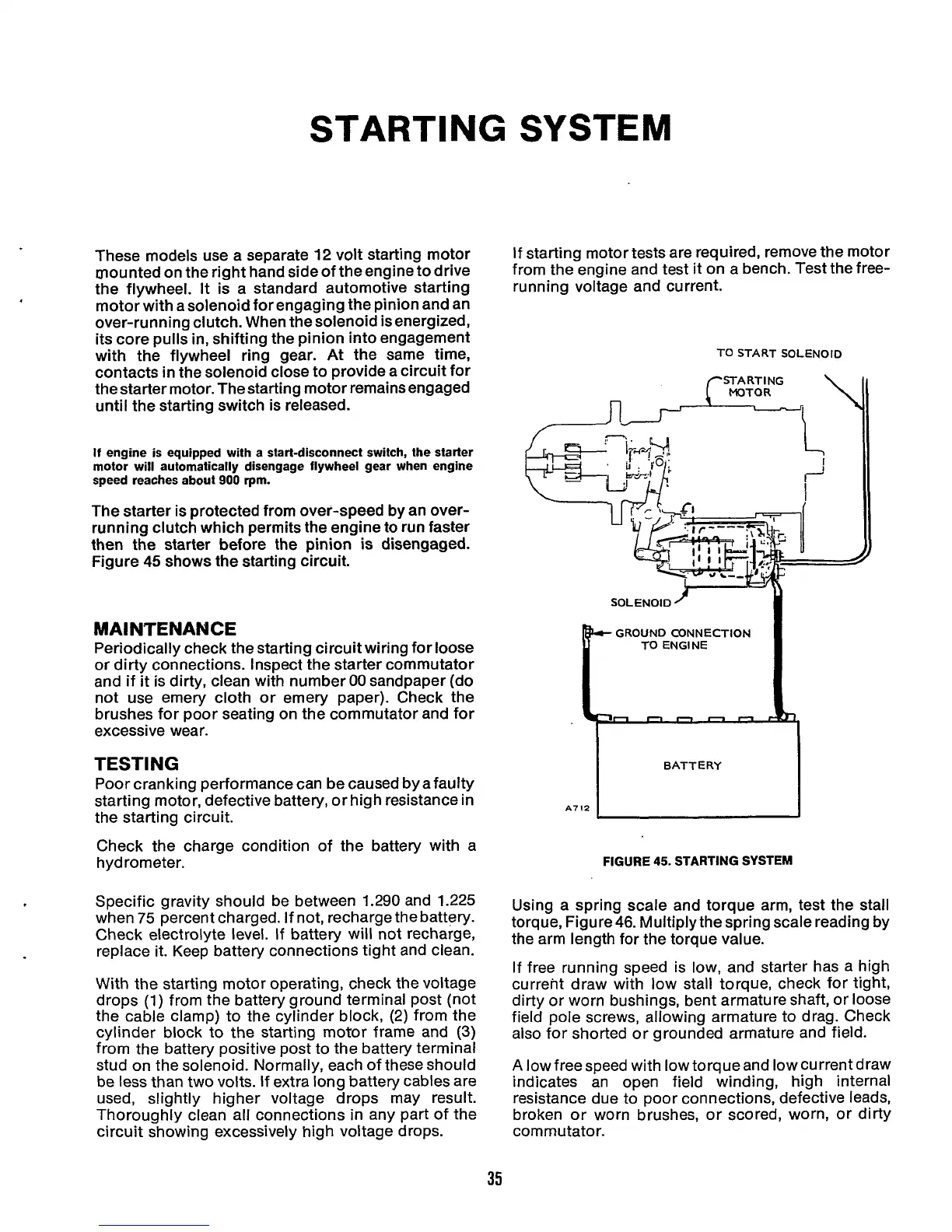

Figure

45

shows the starting circuit.

MAINTENANCE

Periodically check the starting circuit wiring for loose

or dirty connections. Inspect the starter commutator

and if

it

is dirty, clean with number

00

sandpaper (do

not use emery cloth or emery paper). Check the

brushes for poor seating on the commutator and for

excessive wear.

TESTING

Poor cranking performance can be caused bya faulty

starting motor, defective battery, or high resistance in

the starting circuit.

Check the charge condition of the battery with a

hydrometer.

Specific gravity should be between 1.290 and 1.225

when

75

percent charged. If not, recharge the battery.

Check electrolyte level.

If

battery will not recharge,

replace it. Keep battery connections tight and clean.

With

the starting motor operating, check the voltage

drops

(1)

from the battery ground terminal post (not

the cable clamp) to the cylinder block, (2) from the

cylinder block to the starting motor frame and

(3)

from the battery positive post to the battery terminal

stud on the solenoid. Normally, each of these should

be less than two volts.

If

extra long battery cables are

used, slightly higher voltage drops may result.

Thoroughly clean all connections in any part of the

circuit showing excessively high voltage drops.

If

starting motor tests are required, remove the motor

from the engine and test it on a bench. Test the free-

running voltage and current.

TO

START SOLENOID

GROUND CONNECTION

TO

ENGINE

nnnnn

FIGURE

45.

STARTING SYSTEM

Using a spring scale and torque arm, test the stall

torque, Figure

46.

Multiply the spring scale reading by

the arm length for the torque value.

If

free running speed is low, and starter has a high

current draw with low stall torque, check for tight,

dirty or worn bushings, bent armature shaft, or loose

field pole screws, allowing armature

to

drag. Check

also for shorted or grounded armature and field.

A

lowfreespeed with lowtorqueand low currentdraw

indicates an open field winding, high internal

resistance due to poor connections, defective leads,

broken or worn brushes, or scored, worn, or dirty

commutator.

35

Loading...

Loading...