COOLING

SYSTEM

RADIATOR

COOLED

SYSTEM

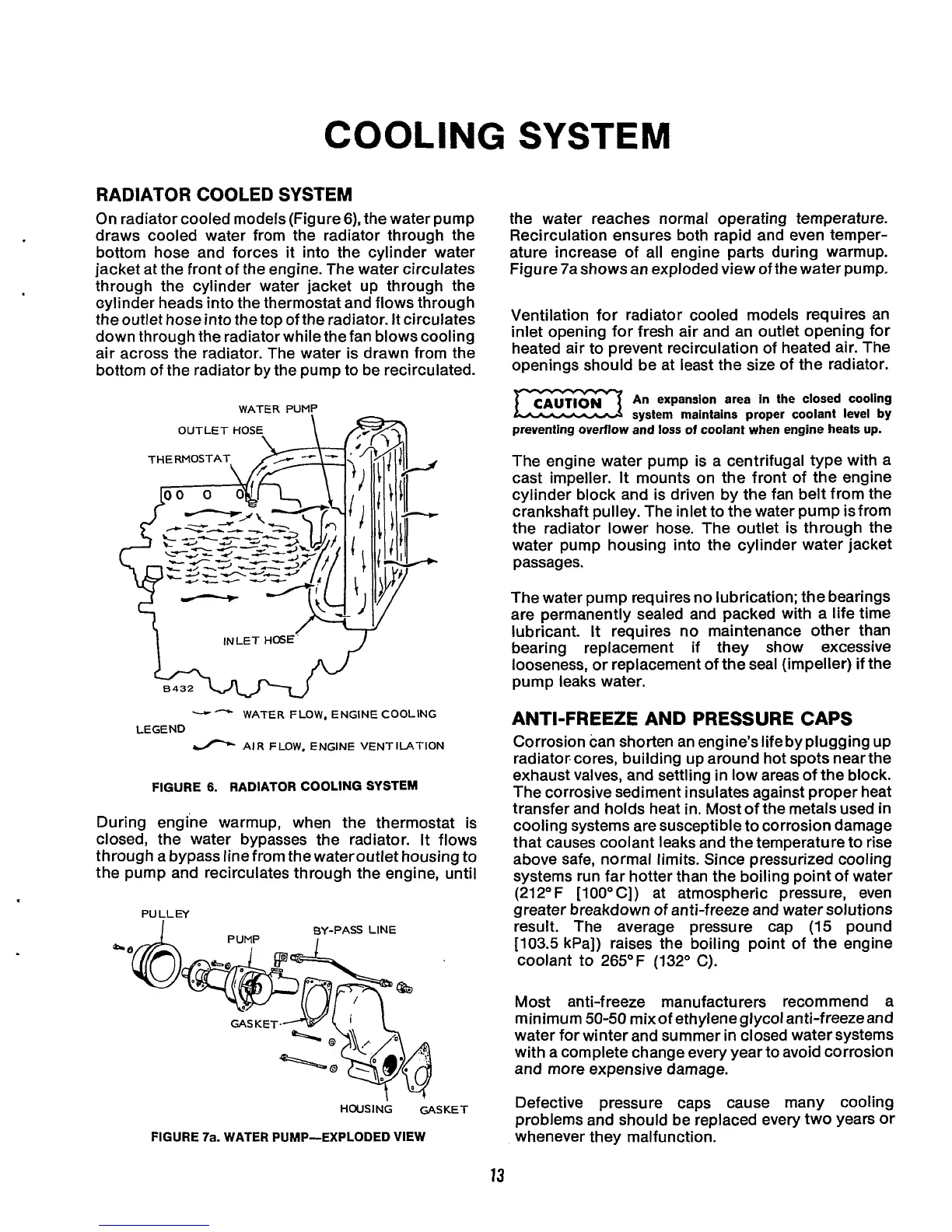

On radiator cooled models (Figure 6), the water pump

draws cooled water from the radiator through the

bottom hose and forces it into the cylinder water

jacket at the front of the engine. The water circulates

through the cylinder water jacket up through the

eylinder heads into the thermostat and flows through

the outlet hose into the top of the radiator. It circulates

down through the radiator while the fan blows cooling

air across the radiator. The water is drawn from the

bottom of the radiator by the pump to be recirculated.

WATER PUMP

--

WATER

FLOW,

ENGINE COOLING

c/"L

AIR

FLOW,

ENGINE VENTILATION

LEGEND

FIGURE

6.

RADIATOR

COOLING SYSTEM

During engine warmup, when the thermostat is

closed, the water bypasses the radiator.

It

flows

through a bypass line from the wateroutlet housing to

the pump and recirculates through the engine, until

PUGLEY

HOUSING GASKET

FIGURE 7a. WATER PUMP-EXPLODED VIEW

the water reaches normal operating temperature.

Recirculation ensures both rapid and even temper-

ature increase of all engine parts during warmup.

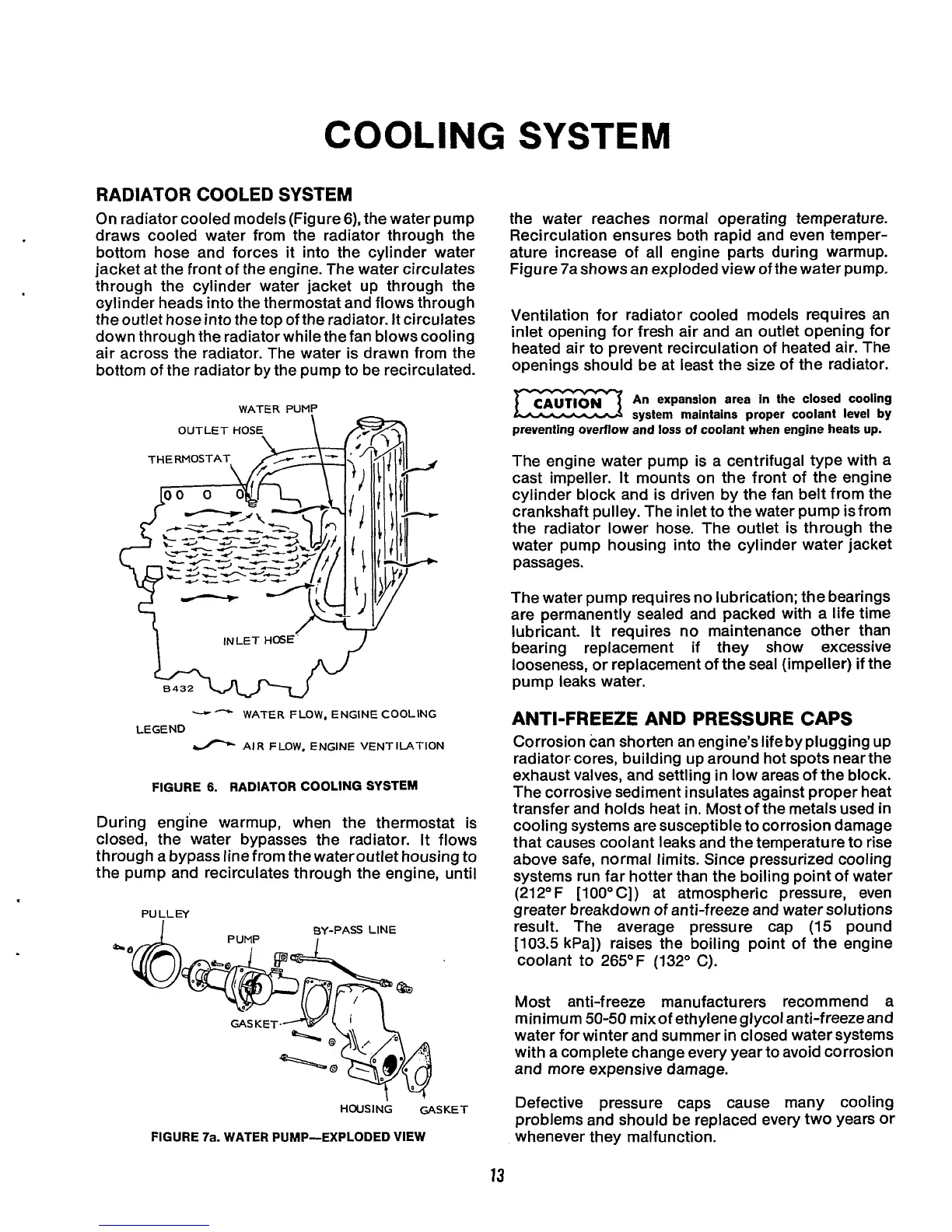

Figure 7a shows an exploded view of the water pump.

Ventilation for radiator cooled models requires an

inlet opening for fresh air and an outlet opening for

heated air to prevent recirculation of heated air. The

openings should be at least the size of the radiator.

An expansion area in the closed cooling

system maintains proper coolant level by

preventing overflow and

loss

of

coolant when engine heats

up.

The engine water pump is a centrifugal type with a

cast impeller.

It

mounts on the front of the engine

cylinder block and is driven by the fan belt from the

crankshaft pulley. The inlet to the water pump isfrom

the radiator lower hose. The outlet is through the

water pump housing into the cylinder water jacket

passages.

The water pump requires no lubrication; the bearings

are permanently sealed and packed with a life time

lubricant. It requires no maintenance other than

bearing replacement if they show excessive

looseness, or replacement of the seal (impeller) if the

pump leaks water.

ANTI-FREEZE AND PRESSURE CAPS

Corrosion can shorten an engine's

life

by plugging up

radiator. cores, building up around hot spots near the

exhaust valves, and settling in low areas of the block.

The corrosive sediment insulates against proper heat

transfer and holds heat in. Most of the metals used

in

cooling systems are susceptible to corrosion damage

that causes coolant leaks and the temperature to rise

above safe, normal limits. Since pressurized cooling

systems run far hotter than the boiling point of water

(212°F [lOO"C]) at atmospheric pressure, even

greater breakdown

of

anti-freeze and water solutions

result. The average pressure cap

(15

pound

[103.5 kPa]) raises the boiling point of the engine

coolant to 265OF (132"

C).

Most anti-freeze manufacturers recommend

a

minimum 50-50 mixof ethyleneglycol anti-freezeand

water for winter and summer in closed water systems

with a complete change every year to avoid corrosion

and more expensive damage.

Defective pressure caps cause many cooling

problems and should be replaced every two years

or

whenever they malfunction.

13

Loading...

Loading...