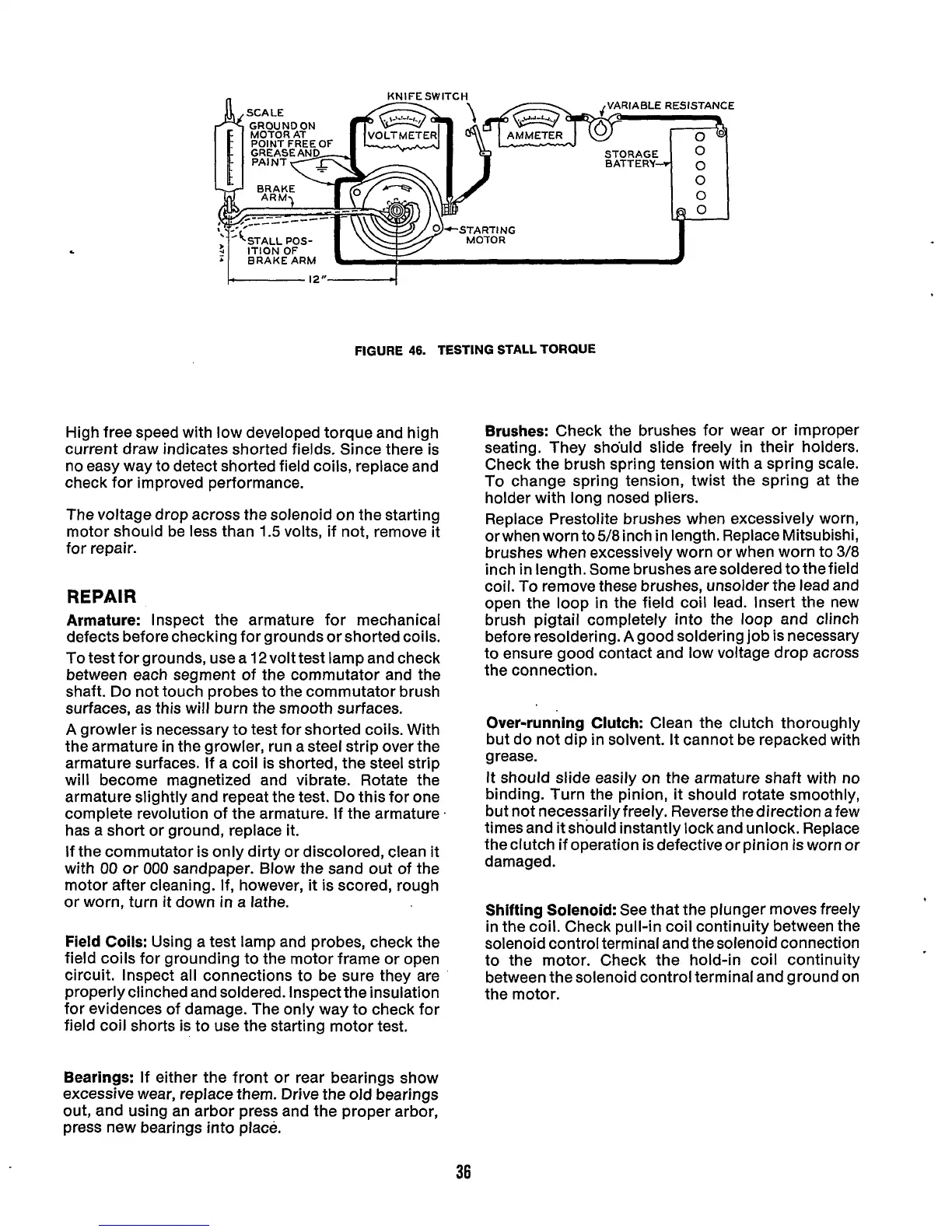

VARIABLE RESISTANCE

STALL

POS-

BRAKE

ARM

I----

12"-4

FIGURE

46.

TESTING

STALL

TORQUE

High free speed with low developed torque and high

current draw indicates shorted fields. Since there is

no easy way to detect shorted field coils, replace and

check for improved performance.

The voltage drop across the solenoid on the starting

motor should be less than

1.5

volts, if not, remove it

for repair.

REPAIR

Armature:

Inspect the armature for mechanical

defects before checking for grounds or shorted coils.

To

test for grounds, use a l2volt test lamp and check

between each segment of the commutator and the

shaft.

Do

not touch probes to the commutator brush

surfaces, as this will burn the smooth surfaces.

A

growler is necessary to test for shorted coils. With

the armature in the growler, run a steel strip over the

armature surfaces.

If

a coil is shorted, the steel strip

will become magnetized and vibrate. Rotate the

armature slightly and repeat the test.

Do

this for one

complete revolution of the armature. If the armature

has a short or ground, replace it.

If the commutator is only dirty or discolored, clean

it

with

00

or

000

sandpaper. Blow the sand out of the

motor after cleaning.

If,

however,

it

is scored, rough

or worn, turn it down in a lathe.

Field Coils:

Using a test lamp and probes, check the

field coils for grounding to the motor frame or open

circuit. Inspect all connections to be sure they are

properly clinched and soldered. Inspect the insulation

for evidences of damage. The only way to check for

field coil shorts is to use the starting motor test.

Brushes:

Check the brushes for wear or improper

seating. They should slide freely in their holders.

Check the brush spring tension with a spring scale.

To change spring tension, twist the spring at the

holder with long nosed pliers.

Replace Prestolite brushes when excessively worn,

orwhen worn to 5/8inch in length. Replace Mitsubishi,

brushes when excessively worn or when worn to 3/8

inch in length. Some brushes aresoldered to the field

coil. To remove these brushes, unsolder the lead and

open the loop in the field coil lead. Insert the new

brush pigtail completely into the loop and clinch

before resoldering.

A

good soldering job is necessary

to ensure good contact and low voltage drop across

the connection.

Over-running Clutch:

Clean the clutch thoroughly

but do not dip in solvent.

It

cannot be repacked with

grease.

It should slide easily on the armature shaft with no

binding. Turn the pinion,

it

should rotate smoothly,

but not necessarily freely. Reverse the direction a few

times and

it

should instantly lock and unlock. Replace

the clutch if operation is defective or pinion is worn

or

damaged.

Shifting Solenoid:

See that the plunger moves freely

in the coil. Check pull-in coil continuity between the

solenoid control terminal and the solenoid connection

to the motor. Check the hold-in coil continuity

between thesolenoid control terminal and ground on

the motor.

Bearings:

If either the front or rear bearings show

excessive wear, replace them. Drive the

old

bearings

out, and using an arbor press and the proper arbor,

press new bearings into place.

36

Loading...

Loading...