12

D1VW_EE 5715-690 UK.indd 11.07.22

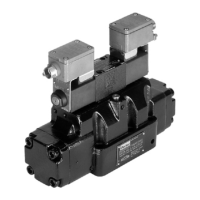

Directional Control Valve

Series D1VW Explosion Proof

Operating Instructions

Parker Hannin Corporation

3. Important information

Correct use

These operating instructions apply to DC

valves of series D1VW*EE, which are inten-

ded solely for use in mineral oil based hyd-

raulic systems (DIN 51524).

Compliance with the operating instructions must be

ensured.

It is the responsibility of the operator to ensure that

the information in the technical data is followed.

Any dierent or modied use is not classed as correct

use.

The manufacturer's warranty will not cover any re-

sulting damage.

Common instructions

We reserve the right to make technical changes as

a result of further development of the product descri-

bed in these operating instructions. Figures and

drawings in these instructions are simplied depicti-

ons. As a result of further development, improve-

ments and changes to the product, it is possible that

the gures are not fully consistent with the described

valve.

The technical details and dimensions are non-bin-

ding. They may not form the basis of any claims.

Copyright reserved.

Liability

The manufacturer cannot accept liability for loss or

damage resulting from the following faults:

• incorrect installation

• unqualied operation

• inadequate maintenance

• use beyond specication

Do not dismantle the valve. If you suspect a

defect, return the valve to Parker.

Storage

If the valve needs to be temporarily stored, it must

be protected from dirt, the weather, and mechanical

damage. Each valve is tested with hydraulic oil in the

factory, so that the internal components are protected

from corrosion. However, this protection can only be

guaranteed under the following conditions:

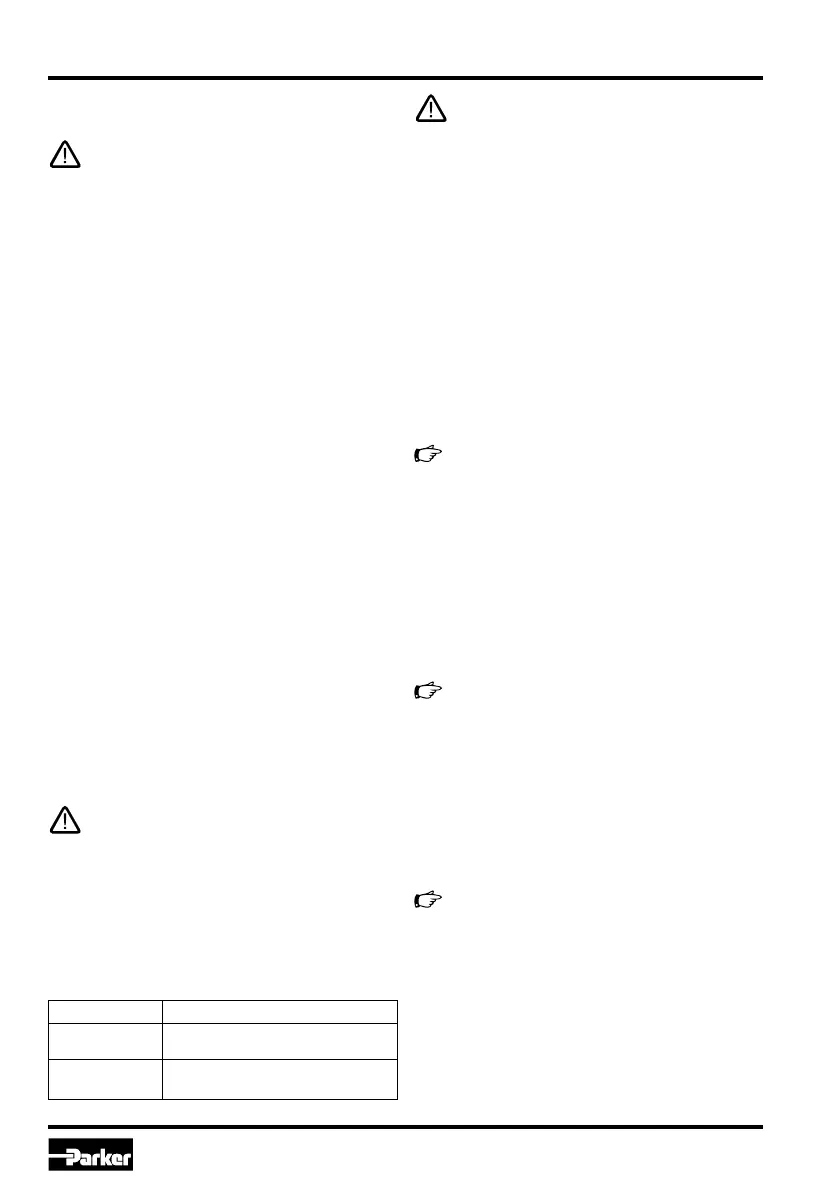

Storage time Storage requirements

12 months constant air humidity < 60 %

constant temperature < 25 °C

6 months varying air humidity,

varying temperature < 35 °C

Storage outside or in maritime or tropical

climates leads to corrosion and may make

the valve unusable.

4. Installation

Scope of delivery

As soon as you receive the valve you should check

if the package has the specied contents. In parti-

cular, check whether the type of protection indica-

ted on the valve is as described in these operating

instructions.

The scope of delivery includes:

• Valve

• Operating instructions (including operating in-

structions of the valve as well as of the soleno-

id and the declarations of conformity of the

manufactures)

As soon as you receive the shipment, please

check for any obvious signs of damage

caused by careless transport. Document the

transport damage and immediately notify the

carrier, the insurance company and the

supplier.

Installation

• Compare the valve type as stated on the

Name plate with the parts list/circuit diagram.

• The valve can be installed in any position, eit-

her xed or movable.

Check the xing surface and the cavity for the

valve. Permitted values: unevenness 0.01

mm/100 mm, roughness Rmax = 6.3 μm. Keep

the valve mounting surface and the area clean.

• Before installation, remove the protective co-

ver from the valve ports.

• Check that the valve ports and the O-rings are

in the correct position.

• Use fastening screws as indicated in the cata-

logue, property class 12.9 to ISO 4762.

Parker can supply the correct screw sets,

see the catalogue for order numbers.

• Tighten the screws diagonally, torque as spe-

cied in the catalogue.

• Any deciencies of the valve mounting surface

may result in operating disruptions. Faulty -

xing and incorrect screw tightening torques

may lead to the sudden escape of hydraulic

uid at the ports.

The valve must be connected to the equipotential

bonding system of the hydraulic system.

Loading...

Loading...