14

D1VW_EE 5715-690 UK.indd 11.07.22

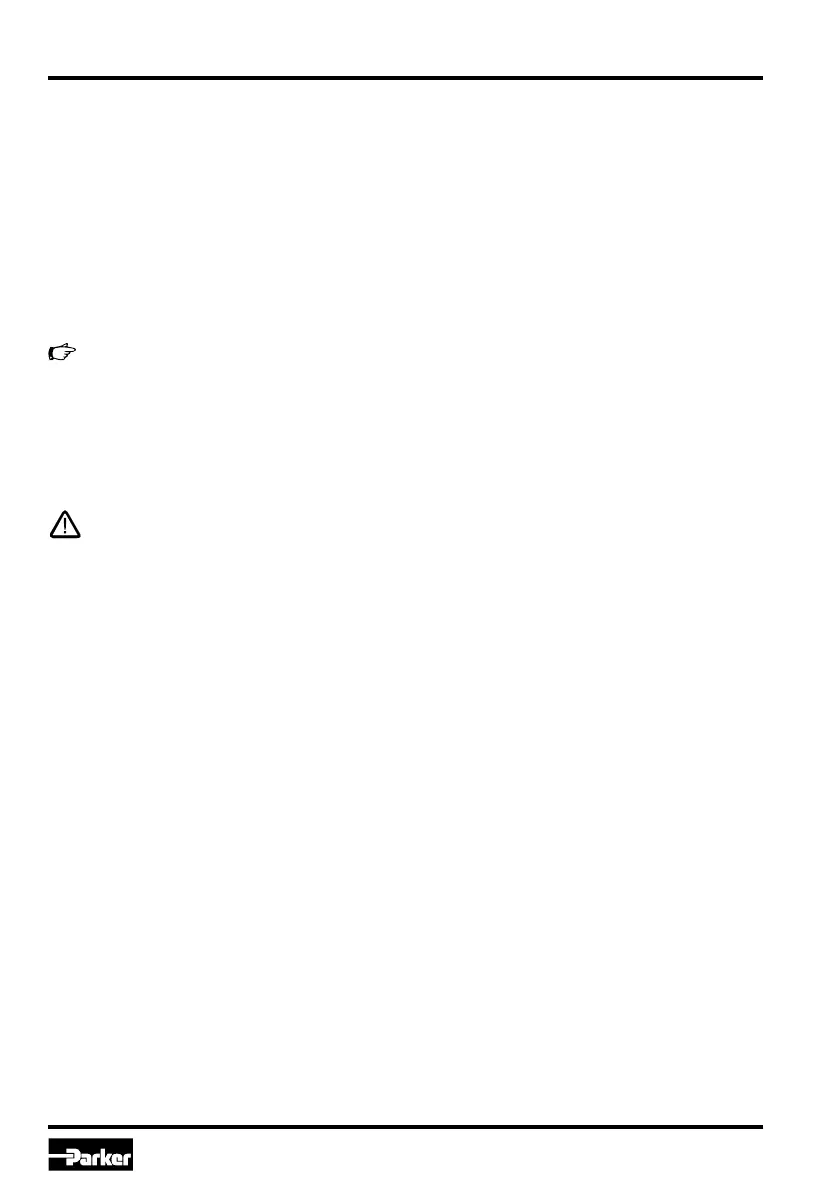

Directional Control Valve

Series D1VW Explosion Proof

Operating Instructions

Parker Hannin Corporation

5. Operating instructions

Air bleeding of hydraulic system

During initial startup, after an oil change as well as

after the opening of lines or valves the hydraulic

system must be air bleeded.

Filter

The function and lifetime of the valve are strongly

aected by the cleanliness of the uid.

Purity level class of 18/16/13 acc. ISO4406 is

required.

Pay attention to maintenance details!

Flushing

It is recommended to ush the pipelines by short

circuiting the pressure and return lines. This pre-

vents the installation dirt from entering the valve.

6. Maintenance

Maintenance procedures may only be car-

ried out by specialist personnel. A detailed

knowledge is required of how the machine

is switched on and o and also of the ne-

cessary safety measures.

Regular maintenance is essential in prolonging the

service life of the systems, and safeguards plant

safety and operational availability. The following

items must be checked at regular and short intervals:

• Oil level in tank

• Max. medium temperature

• Max. surface temperature

• Condition of the pressure uid (sight check,

colour and smell of hydraulic uid)

• Operating pressures

• Preload pressure of pressure vessel (if pre-

sent)

• No leaks at any system components

• Condition of the lter elements

• Condition of the hose lines

• Cleanliness of components

After a certain period of service, the hydraulic uid

must be replaced. The frequency of the change

depends on the following circumstances:

• Type and grade of pressure uid (ageing)

• Filtration

• Operating temperature and ambient condi-

tions

Replacement of a coil

In case of a necessary replacement of a coil the

disassembly and assembly instructions on dra-

wing 35015707 (see next page) have to be ob-

served. Before exchanging a coil the name plates

of old and new coil have to be checked. It must

be ensured that only coils with identical voltages

are used.

Available coil kits are:

AK-D1VWCJEE93 24 V DC

AK-D1VWCPEE93 110 V / 50 Hz

AK-D1VWCNEE93 230 V / 50 Hz

The coils of series 93 are suitable for valves of

series 91 as well as 92 and 93.

Loading...

Loading...