6

D1VW_EE 5715-690 UK.indd 11.07.22

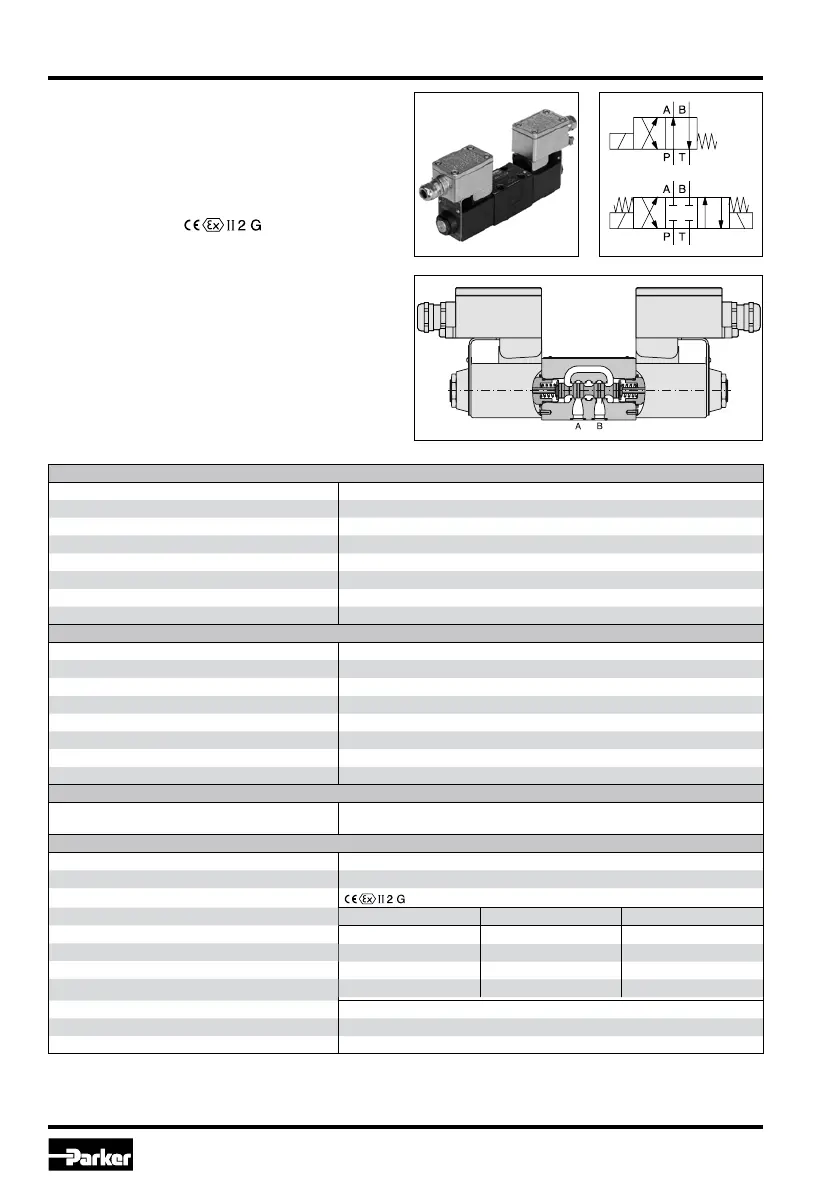

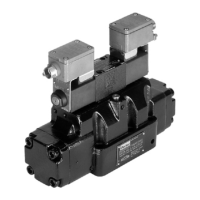

Directional Control Valve

Series D1VW Explosion Proof

Operating Instructions

Parker Hannin Corporation

1. Introduction

The D1VW with explosion proof solenoids is ba-

sed on the standard D1VW series. The specic

solenoid design allows the usage in hazardous

environments.

The explosion proof class is

Ex e mb IIC T4 Gb

for use in zone 1 and 2 (according to ATEX).

Additionally the solenoids are IECEx compliant.

All explosion proof solenoids are DC design. The

valves for AC operate with integrated rectier.

Technical data

General

Design Directional spool valve

Actuation Solenoid

Size DIN NG06 / CETOP 03 / NFPA D03

Mounting interface DIN 24340 A6 / ISO 4401 / CETOP RP 121-H / NFPA D03

Mounting position unrestricted, preferably horizontal

Ambient temperature [°C] -20...+60

MTTF

D

[years] 150

Weight [kg] 1.8 (1 solenoid), 2.7 (2 solenoids)

Hydraulic

Max. operating pressure [bar] P, A B: 350; T: 210

Fluid Hydraulic oil according to DIN 51524

Fluid temperature [°C] -20 ... +60

Viscosity permitted [cSt] / [mm²/s] 2.8...400

Viscosity recommended [cSt] / [mm²/s] 30...80

Filtration ISO 4406 (1999); 18/16/13

Flow max. [l/min] 60 (see shift limits)

Leakage at 50 bar [ml/min] Up to 10 per ow path, depending on spool

Static / Dynamic

Step response at 95 % [ms] Energized: 32 (DC), 40 (AC)

De-energized: 40 (DC), 75 (AC)

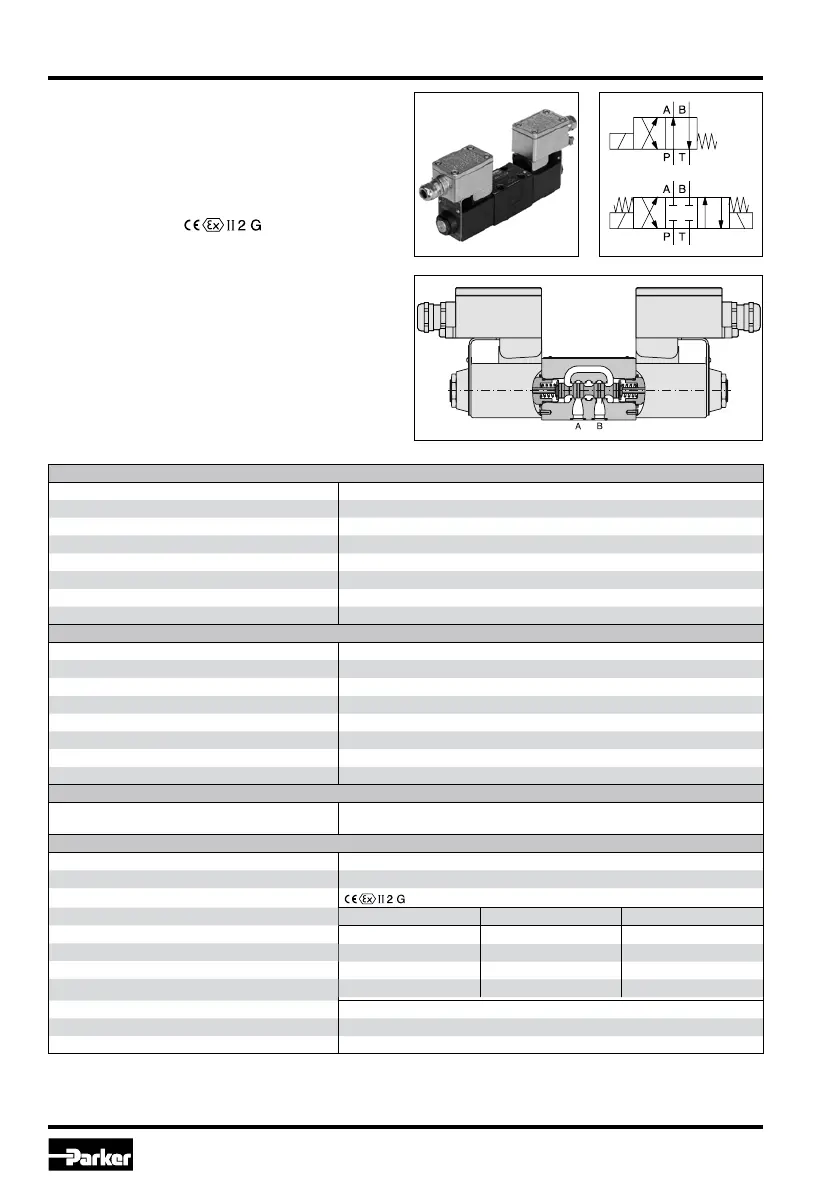

Electrical characteristics

Duty ratio 100 % ED; CAUTION: coil temperature up to 135 °C possible

Max. switching frequency [1/h] 15000 (DC), 7200 (AC)

Protection class

, Ex e mb IIC T4 Gb, IP66 (plugged and mounted correctly)

Code

J N P

24 V = 230/50 Hz 110/50 Hz

±10 ±10 ±10

1.0 0.12 0.25

24 24 24

Supply voltage / ripple [V]

Tolerance supply voltage [%]

Current consumption [A]

Power consumption [W]

Solenoid connection

Box with M20x1.5 entry for cable glands. Solenoid identication as per ISO 9461.

Wiring min. [mm²] 3 x 1.5 recommended

Wiring length max. [m] 50 recommended

With electrical connections the protective conductor (PE W) must be connected according to the relevant regulations.

Loading...

Loading...