13

CY

IE NI

10. Fold the safety device (6) up-

wards. Insert the chuck (4) on

the taper of the drill spindle (7).

Push the drill chuck onto the drill

chuck tip with a few light taps.

Use a plastic hammer for this

purpose.

Operation

Caution! Risk of injury!

- Ensure that you have sufcient

space in which to work and that

you do not endanger other peo-

ple.

- All hoods and protective devices

must be assembled properly be-

fore commissioning.

- Disconnect the mains plug be-

fore changing the setting on the

device.

Setting up

Place the bench drill on a solid surface.

Ideally, bolt the drill to the surface. Use the

four holes in the baseplate (17) for this.

Selecting the speed

1. Release the locking bolt (11) on the

gear cover (3).

2. Open the gear cover (3).

3. Release the retaining screw (12) on the

motor unit (13).

4. Using the lever (33), slide the motor

unit (13) forwards a little to release the

load on the V-belts (29).

5. Place the V-belts (29) on the desired

assembly to reach the specied speed:

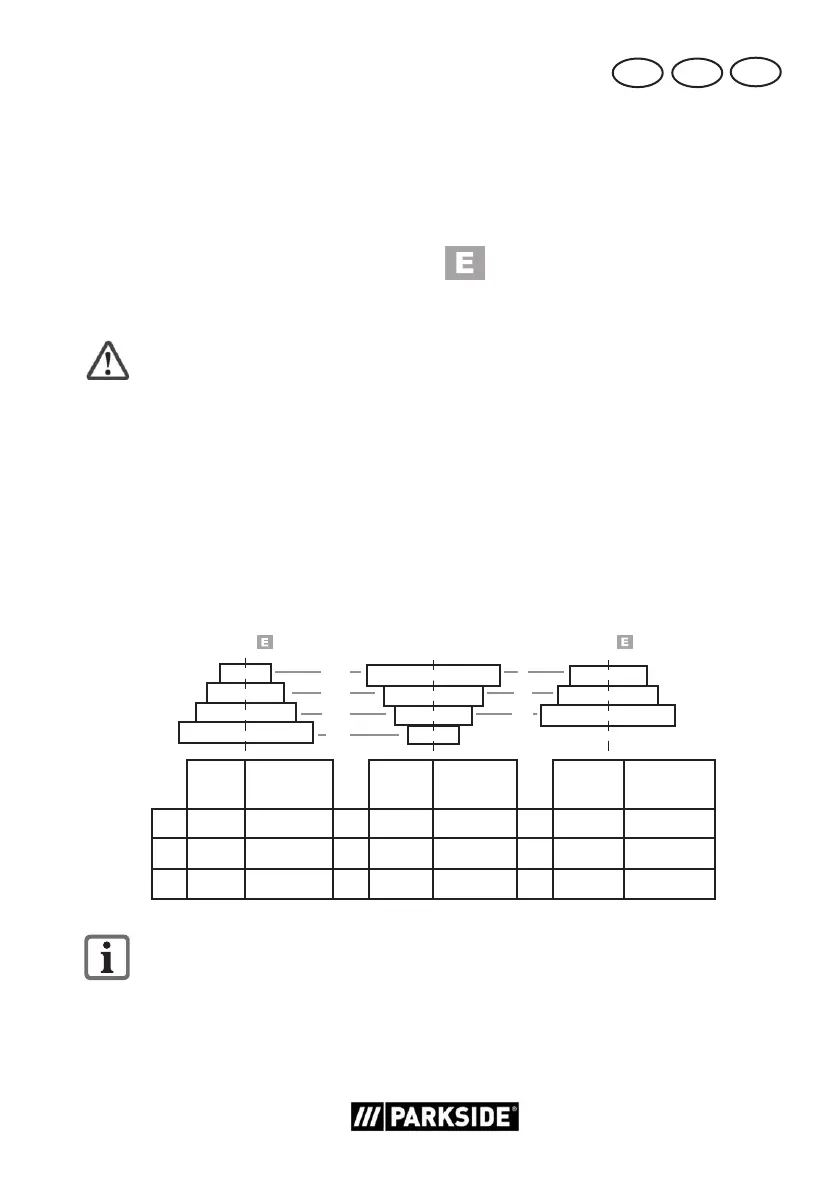

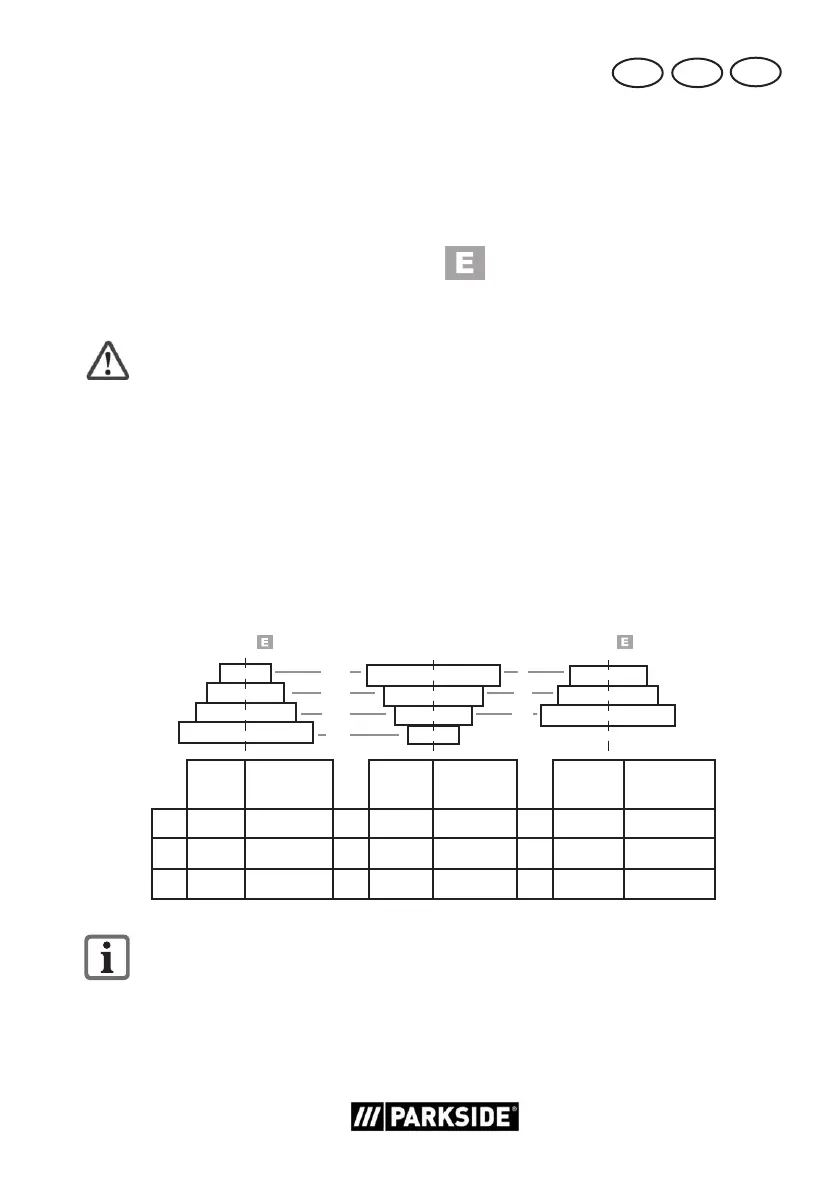

A

B

C

D

I

II

III

Spindle-side drive

pulley ( 30)

Motor side drive

pulley (

31)

Pos.

speed

[1/min]

Pos.

speed

[1/min]

Pos.

speed

[1/min]

1. D - I 500 4. D - III 830 7. B - III 1600

2. D - II 680 5. B - I 980 8. A - II 2000

3. C - I 770 6. C - II 1100 9. A - III 2500

The gear cover (3) is equipped with a interlock switch (32). If the gear cover (3) is

not closed correctly, the device cannot be switched on.

6. Using the lever (33), slide the motor

unit (13) backwards to re-tighten the V-

belts (29).

7. The V-belts (29) are correctly tensioned

when they give way slightly when

pressed.

Loading...

Loading...