I

\ i i

ERON[

ID

_ EQUALIZER

X

REAR

FRONT REAR

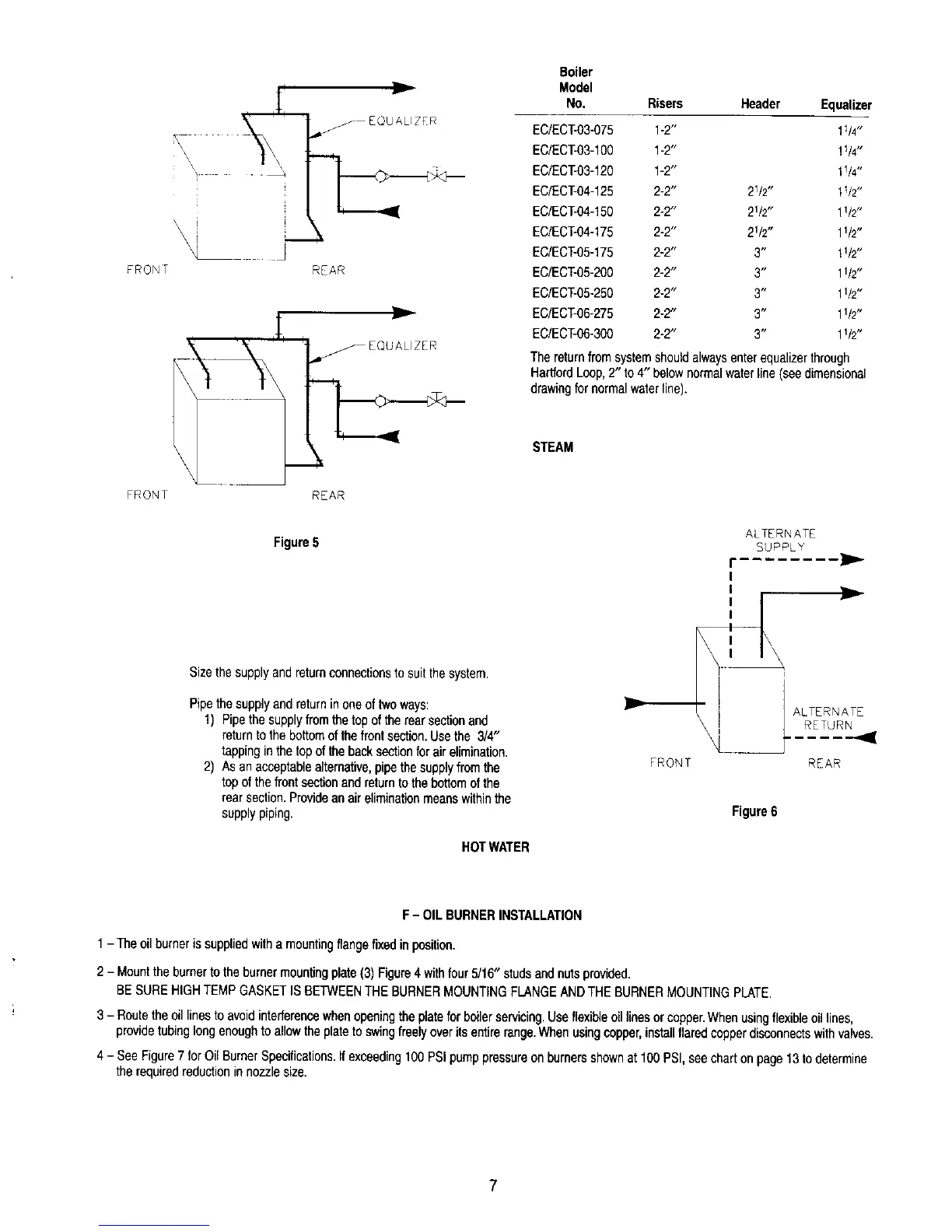

Boiler

Model

No, Risers Header Equalizer

EC/ECT-03-075 1-2" 11/4"

EC/ECT-03-1O0 1-2" 1V4"

EC/ECT-03-120 1-2" 1V4"

EC/ECT-04-125 2-2" 21/2', 11/2"

EC/ECT-04-150 2-2" 21/2", 11/2"

EC/ECT-04-175 2-2" 21/2" 11/2"

EC/ECT-05-175 2-2" 3" 11/2"

EC/ECT-05-200 2-2" 3" 11/2"

EC/ECT-05-250 2-2" 3" 11/2"

EC/ECT-06-275 2-2" 3" 1112"

EC/ECT-06-300 2-2" 3" 11/2"

Thereturnfrom systemshouldalwaysenterequalizerthrough

HartfordLoop,2" to4" belownormalwaterline (see dimensional

drawingfor normalwaterline).

STEAM

Figure5

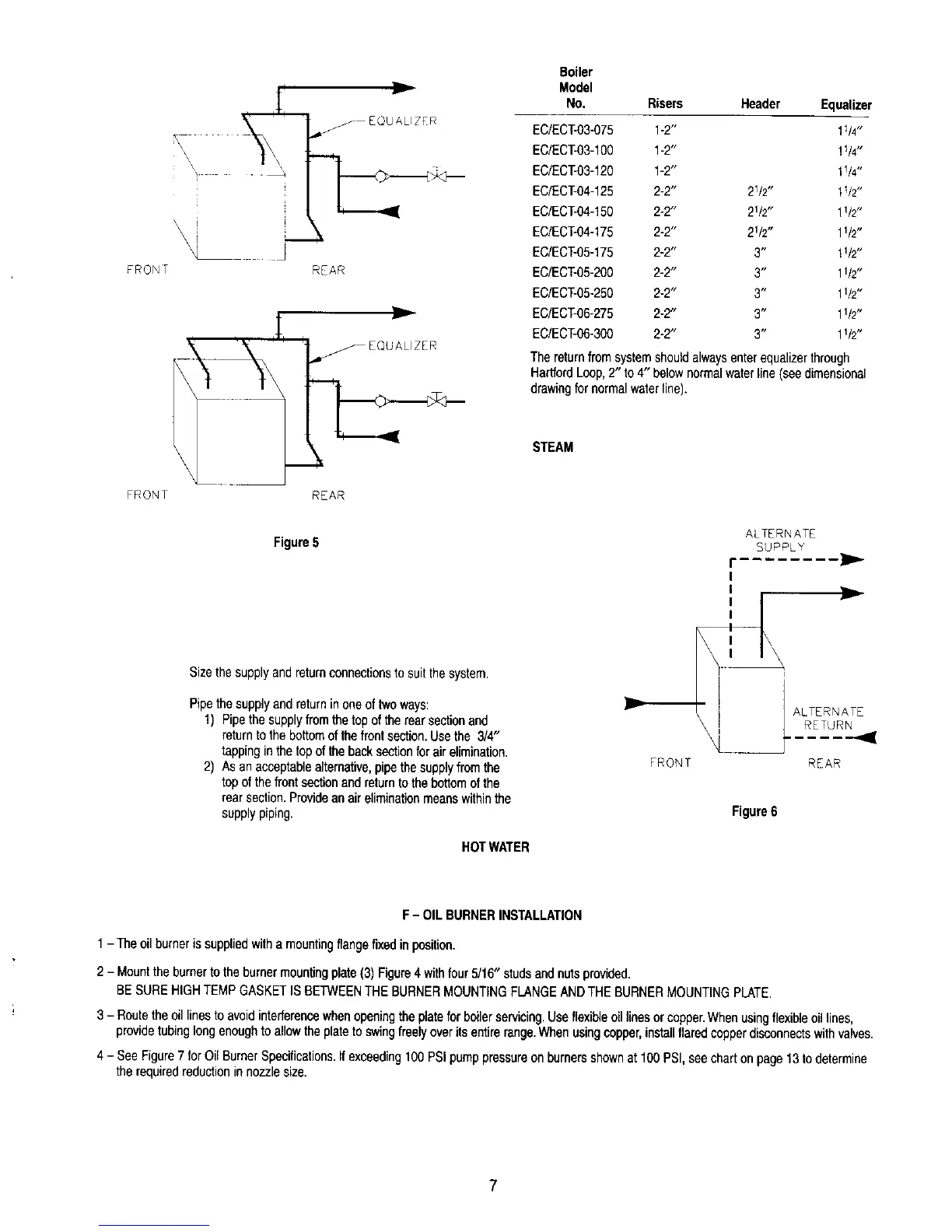

Size thesupplyand returnconnectionsto suit thesystem.

Pipethe supplyand returninoneoftwo ways:

1) Pipethesupplyfromthetop ofthe rearsectionand

returntothe bottomof thefrontsection.Use the 3/4"

tappinginthe topof thebacksectionfor airelimination.

2) As anacceptablealternative,pipethe supplyfromthe

topof thefrontsectionandreturnto the bottomofthe

rearsection.Providean aireliminationmeanswithinthe

supplypiping.

HOTWATER

ALTERNATE

SUPPLY

FRONT

r

ALTERNATE

RETURN

REAR

Figure6

F- OILBURNERINSTALLATION

1- Theoilburneris suppliedwitha mountingflangefixedinposition.

2 - Mountthe burnerto theburnermountingplate(3) Figure4 withfour5/16" studsandnuts provided.

BESUREHIGHTEMPGASKETIS BETWEENTHEBURNERMOUNTINGFLANGEANDTHE BURNERMOUNTINGPLATE.

3 - Routethe oillinesto avoidinterferencewhenopeningthe platefor boilerservicing.Useflexibleoillinesor copper.Whenusingflexibleoillines,

providetubinglongenoughto allowthe plateto swingfreelyover itsentirerange.Whenusingcopper,installflaredcopperdisconnectswithvalves.

4 - See Figure7 for OilBurnerSpecifications.If exceeding100PSIpumppressureon burnersshownat 100 PSI,seechart onpage13to determine

therequiredreductionin nozzlesize.

7

Loading...

Loading...