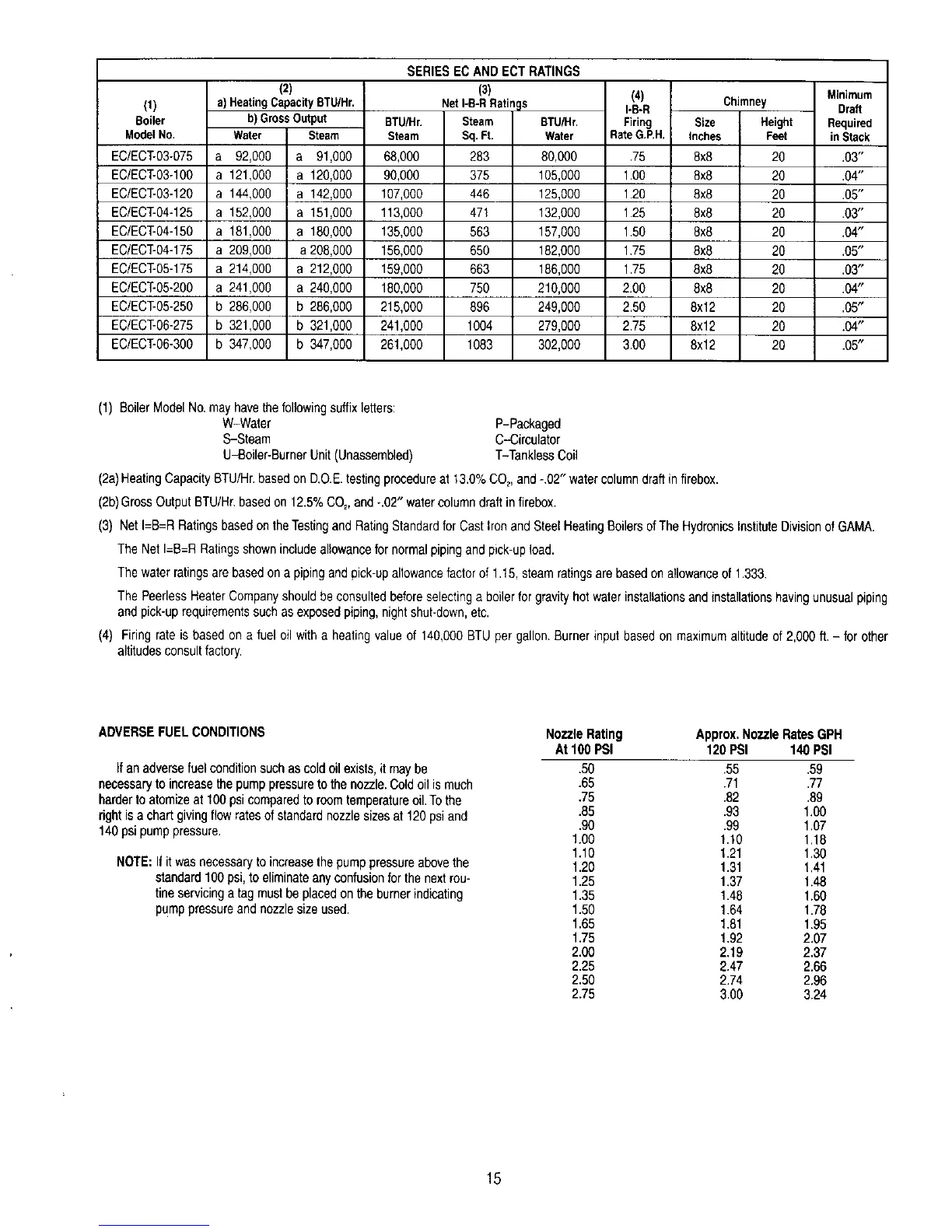

(1)

Boiler

ModelNo,

EC/ECT-03-075

EC/ECT-03-100

EC/ECT-03-120

EC/ECT-04-125

EC/ECT-04-150

EC/ECT-04-175

EC/ECT-05-175

EC/ECT-05-200

EC/ECT-05-250

EC/ECT-06-275

EC/ECT-06-300

(2)

a)HeatingCapacityBTU/Hr.

b)GrossOutput

Water Steam

a 92,000 a 91,000

a 121,000 a 120,000

a 144,008 a 142,000

a 152,000 a 151,000

a 181,000 a 180,000

a 209,000 a 208,000

a 214,000 a 212,000

a 241,000 a 240,000

b 286,000 b 286,000

b 321,000 b 321,000

b 347,000 b 347,000

SERIESECAND ECTRATINGS

(3)

NetI-8-RRatings

BTU/H_ Steam BTU/Hr.

Steam Sq.Ft. Water

68,000 283 80,000

90,000 375 105,000

107,000 446 125,000

113,000 471 132,000

135,000 563 157,000

156,000 650 182,000

159,000 663 186,000

180,000 750 210,000

215,000 896 249,000

241,000 1004 279,000

261,000 1083 302,000

(4)

I-B-R

Firing

RateG.P.H.

.75

1.00

1.20

1.25

1.50

1.75

1.75

2.00

2.50

2.75

3.00

Chimney

Size Height

inches Feet

8x8 20

8x8 20

8x8 20

8x8 20

8x8 20

8x8 20

8x8 20

8x8 20

8x12 20

8x12 20

8x12 20

Minimum

Draft

Required

inStack

,03"

,04"

.05"

.03"

,04 "t

,05"

,03"

.04 _r

,05"

.04 _

.05"

(1) BoilerModel No.mayhavethe followingsuffixletters:

W-Water P-Packaged

S-Steam C-Circulator

Uq3oiler-BurnerUnit (Unassembled) T-TanklessCoil

(2a)HeatingCapacityBTU/Hr.basedon D.O.E.testingprocedureat t3.0% CO_,and -.02" watercolumndraftin firebox.

(2b)GrossOutputBTU/Hr.basedon 12.5%CO=,and -.02"watercolumndraft infirebox.

(3) Net I=B=RRatingsbasedontheTestingand RatingStandardfor Cast Iron andSteelHeatingBoilersofThe HydronicsInstituteDivisionof GAMA.

The Net I=B=RRatingsshownincludeallowancefor normalpipingandpick-upload.

Thewater ratingsare basedona pipingandpick-upaltowancefactorof 1.15,steamratingsarebased ona!lowanceof 1.333.

The PeerlessHeaterCompanyshouldbe consultedbeforeselectinga boilerfor gravityhot waterinstallationsandinstallationshavingunusualpiping

and pick-uprequirementssuchas exposedpiping,nightshut-down,etc.

(4) Firing rate is basedon a fuel oil with a heatingvalueof 140,000BTUper gallon.Burnerinput basedon maximumaltitudeof 2,000ft.- for other

altitudesconsultfactory.

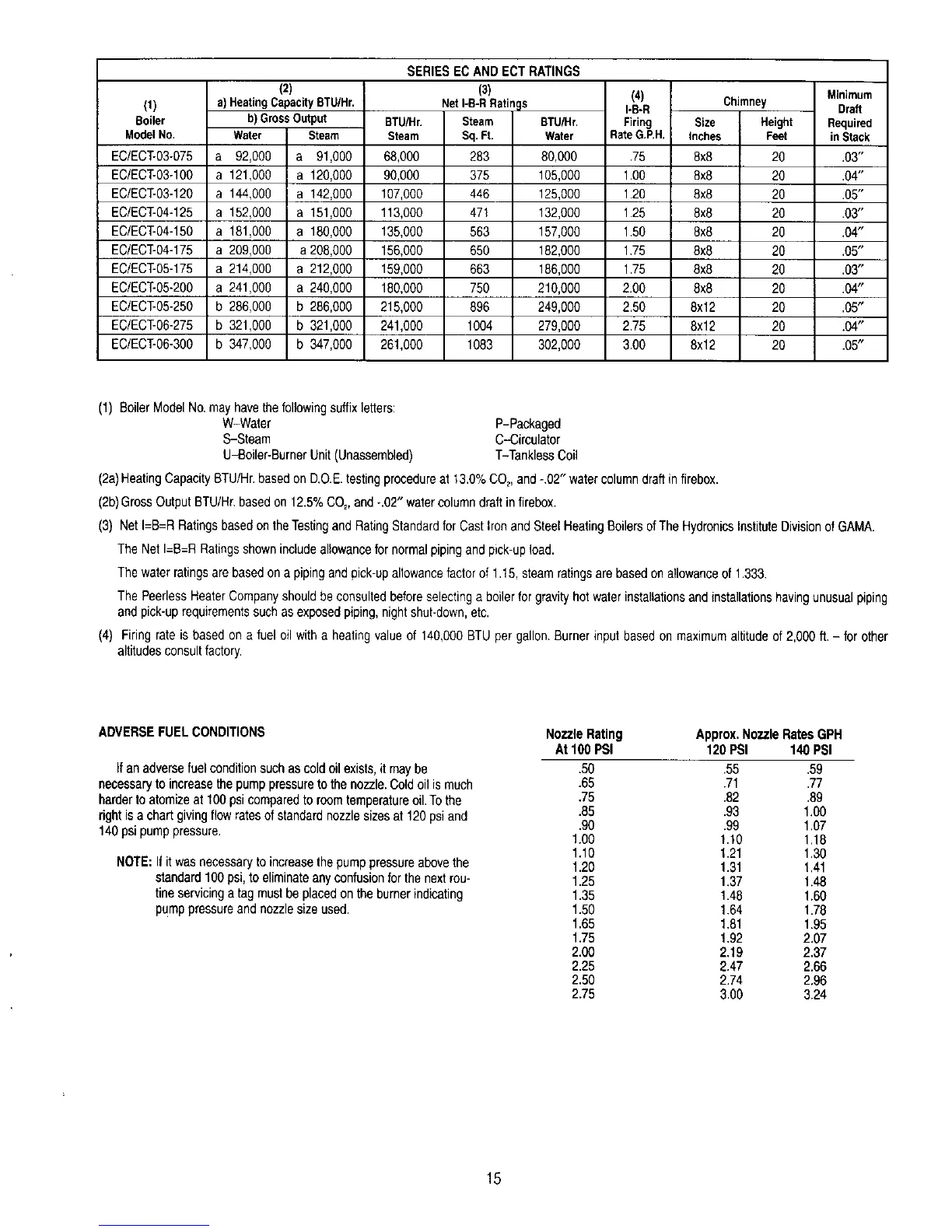

ADVERSEFUELCONDITIONS

If an adversefuelconditionsuchas cold oilexists,it maybe

necessaryto increasethe pumppressureto the nozzle.Coldoil ismuch

harderto atomizeat 100psicomparedto roomtemperatureoil.Tothe

right is a chartgivingflowrates of standardnozzlesizesat 120psi and

140psi pumppressure.

NOTE:If itwasnecessarytoincreasethepumppressureabovethe

standard100psi, to eliminateanyconfusionfor the nextrou-

tine servicinga tag mustbeplacedon theburnerindicating

pumppressureand nozzlesize used.

NozzleRating Approx.NozzleRatesGPH

At 100 PSI 120 PSI 140 PSI

.50 .55 .59

.65 .71 .77

.75 .82 .89

.85 .93 1.00

.90 .99 1.07

1.00 1.10 1.18

1.10 1.21 1.30

1.20 1.31 1.41

1.25 1.37 1.48

1.35 1.48 1.60

1.50 1.64 1.78

1.65 1.81 1.95

1.75 1.92 2.07

2.00 2.19 2.37

2.25 2.47 2.66

2.50 2.74 2.96

2.75 3.00 3.24

15

Loading...

Loading...