INSTALLATIONINSTRUCTIONS- SERIES EC and ECT

Readcarefullybeforebeginningwork.It willsavetime.Studythe includeddrawings.

This boilermust beinstalledby a qualifiedcontractor.

Theboiler warrantycan bevoidedifthe boilerisnot installed,maintained,andserviced correctly.

Theequipmentshallbe installedinaccordancewiththoseinstallationregulationsinforceinthe localareawheretheinstallationisto bemade,includingthe

currenteditionof NFPA-31.Theseshallbecarefullyfollowedin allcases.Authordieshavingjurisdictionshallbeconsultedbeforeinstallationsare made.

A- ACCESSIBILITYCLEARANCES

1 - To provide for reasonableconditionsof accessibilityfor servicing,the following minimumclearancesare recommendedbetweenthe boiler and

adjacentwallsor otherappliances--atleast24" inthe front,rearand onboth sides.

B- AIRFORCOMBUSTIONANDVENTILATION

1 - Becertainadequatefacilitiesare availableto provideairfor satisfactorycombustionandventilation.

2 - AppliancesLocatedin UnconfinedSpaces.

a. For installationsin unconfinedspaceswith conventionalconstructionand largeareas suchas basements,the supplyof air for combustionand

ventilationcanusuallybe consideredadequate.

3 - AppliancesLocatedin ConfinedSpaces.

a. If all air for combustionand ventilationis to comefrom withinthebuilding;two openings,one nearthe ceilingandone nearthe floorof the boiler

roomshall be providedwiththe minimumfreearea ofeachopeningequalto 140sq. in. pergallonof oil burned.

b. If all airfor combustionandventilationis to come fromoutsidethebuilding;twoopenings,one neartheceilingand one nearthefloorof the boiler

roomshall beprovidedwiththeminimumfree areaof eachopeningequalto 35sq. in. par gallonofoil burned.If ductsare usedtoconveytheair,

areasof35 sq.in.per gallonof oil burnedfor verticalductsor 70 sq.in. per gallonofoil burnedfor horizontalductsareto beprovided.Ductsshall

havethesame areaas thefreeareaof theopeningstowhichthey areconnected.

C- SETTINGBOILERBLOCK

1-The Series EC/ECT boiler sectionsare factoryassembledwiththe target wallshipped in place. Providea levelfoundation,locatedas close as

possibleto thecenterofthe heatingsystemandtothechimney.TheheatingsurfaceoftheSedesEC/ECTboilersisdesignedto becleanedfromeither

thetop or left side ofthe unit.Allowadequateclearanceon the leftof unitif servicingisto bedonefromthe side.

2 - Open fluecollectorcarton.Removefluecollector(Item9, Fig. 4) and hightemperaturerope.Lay rope(Item8, Fig.4) ontop of boileragainst bead

provided.Placefluecollectorontop of ropeand attachto boilerwith1/4"-20x 13/4"studswith nutsthroughfluecollectorbracketsintothetappedlugs

providedin thetopof the boilerendsections.Drawnutsdownsnugly.

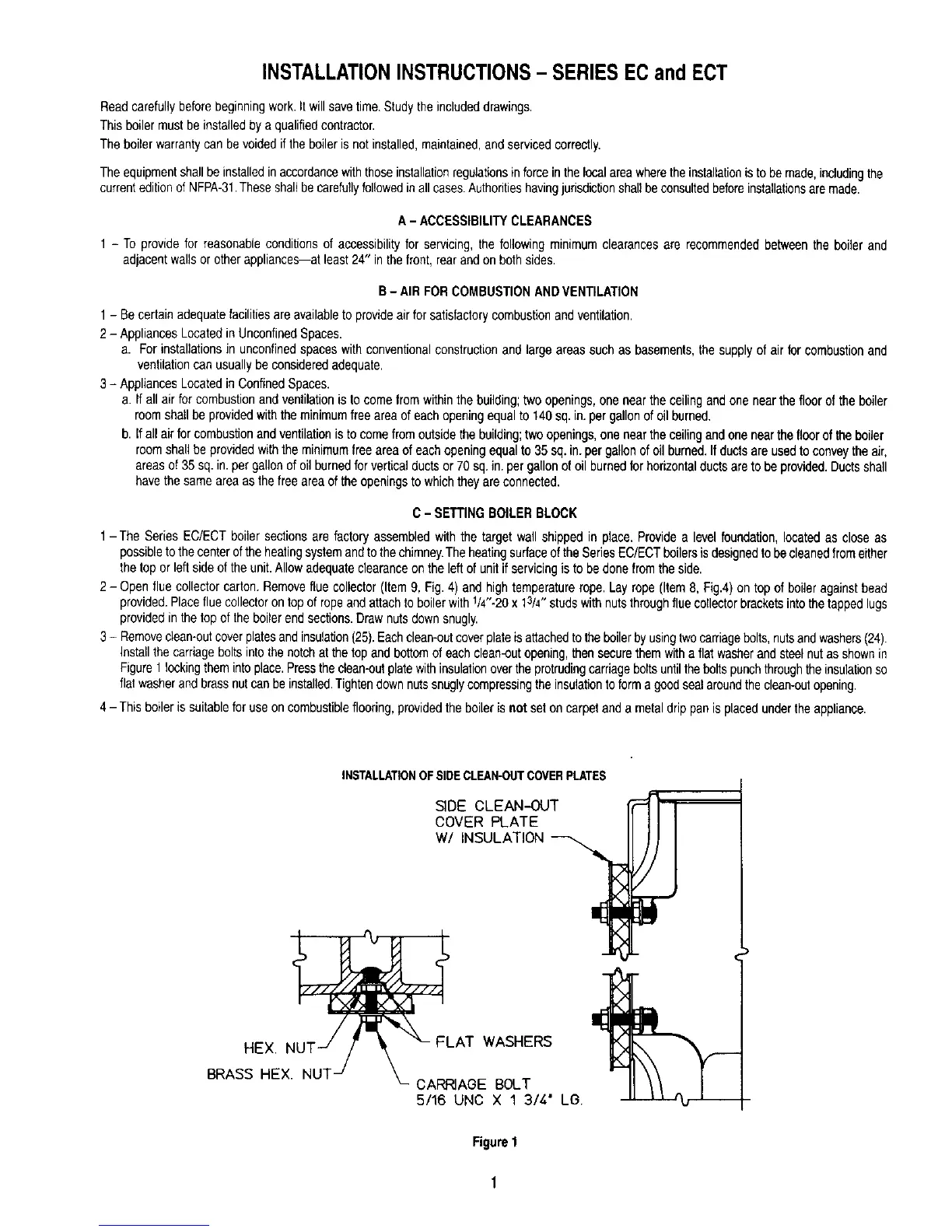

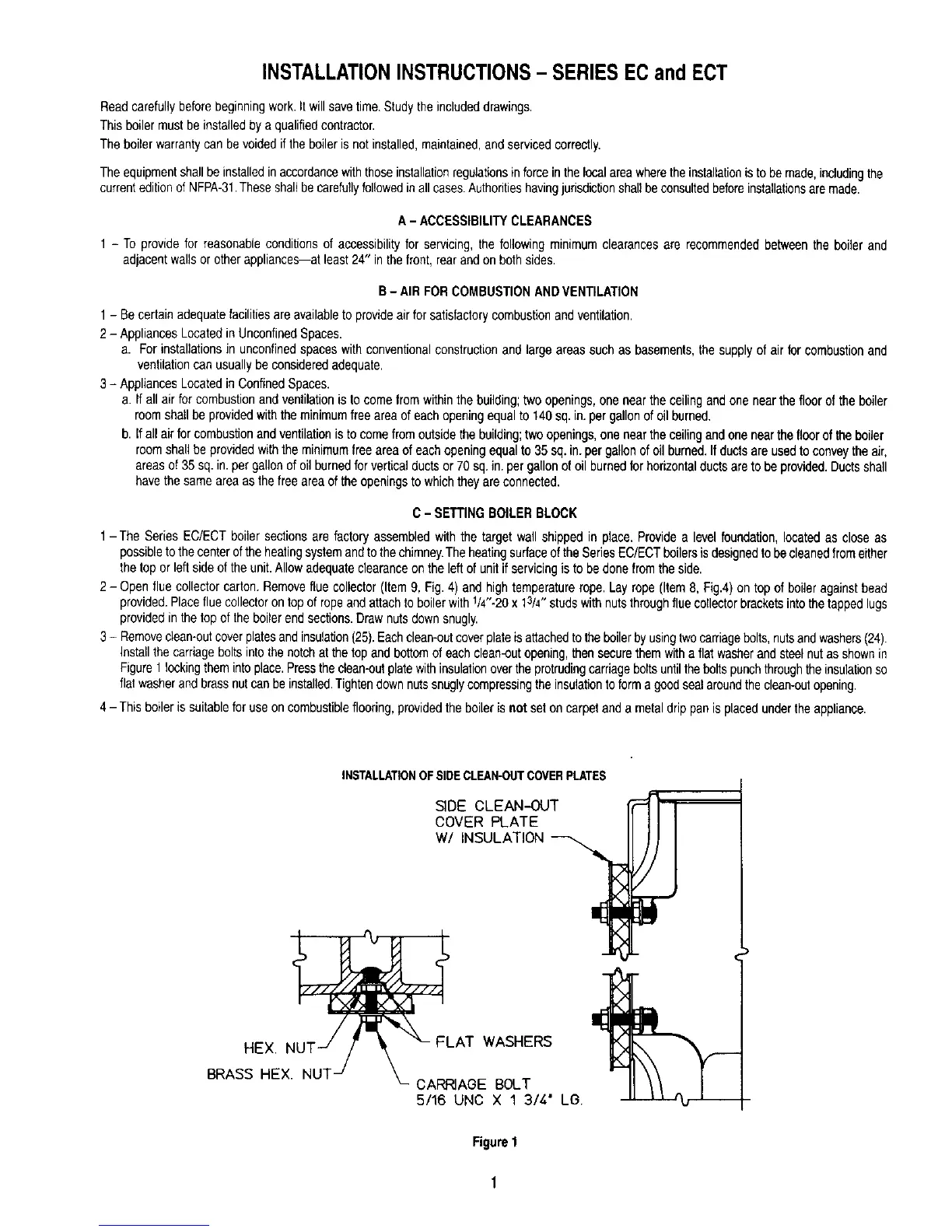

3 - Removeclean-outcoverplatesandinsulation(25).Eachclean-outcoverplateisattachedto the boilerby usingtwo carriagebolts,nutsandwashers(24).

Installthe carriageboltsintothenotchatthe top andbottomof eachclean-outopening,then securethemwith a flat washerand steelnutas shownin

Figure1 lockingthemintoplace.Pressthe clean-outplatewithinsulationoverthe protrudingcarriageboltsuntiltheboltspunchthroughtheinsulationso

flatwasherand brassnutcanbeinstalled,Tightendownnutssnuglycompressingthe insulationto forma goodsealaroundthecleen-outopening,

4 - This boileris suitablefor useon combustibleflooring,providedthe boilerisnot seton carpetand a metaldrip panis placedundertheappliance.

INSTALLATIONOF SIDECLEAN-OUTCOVERPLATES

5/16 UNC X 1 3/4" L(3.

Figure1

Loading...

Loading...