4

S536 (11-25-19)

INSTALLATION

PRIOR TO PUMP INSTALLATION

Prior to pump installation, follow these steps to ensure proper

installation and operations.

1. Well must not be more than 20’ depth to water.

2. Be sure well is clear of sand. Sand will plug the pump and void the

warranty.

3. Protect pump and all piping from freezing. Freezing will split

pipe, damage pump and void the warranty. Check locally for frost

protection requirements. Normally, pipe must 12” below frost line

and pump must be insulated.

4. Be sure all pipes and the foot valve are clean and in good shape.

5. Ensure there are no air pockets or leaks in suction pipe. Use PTEE

pipe thread sealant tape to seal pipe joints.

6. Unions installed near pump and well will aid in servicing but leave

room for using wrenches.

7. Pump body may explode if used as a booster

pump. DO NOT use in a booster appli cation.

WELL PIPE INSTALLATION

Use the installation method below that matches your well type.

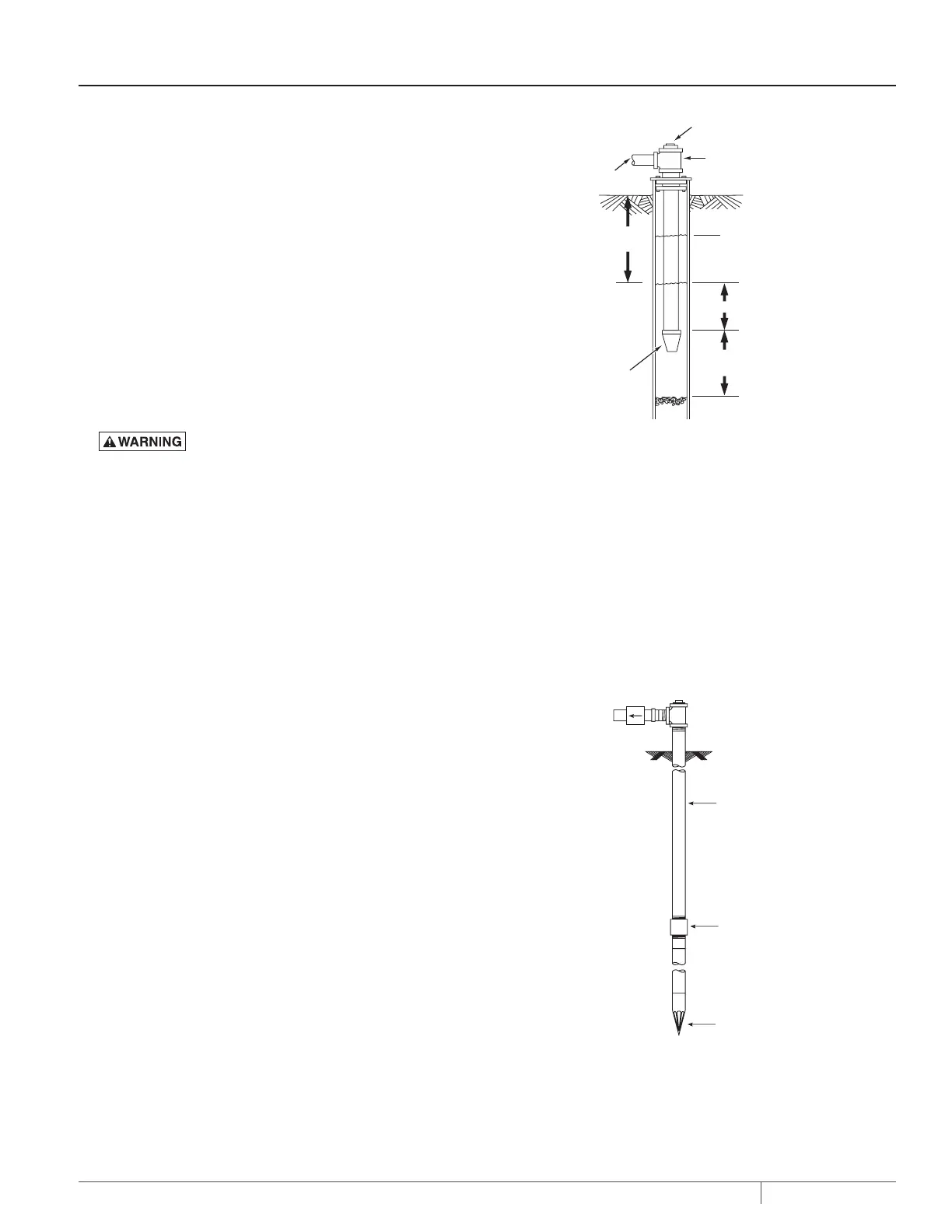

CASED WELL INSTALLATION

1. Inspect foot valve to be sure it works freely. Inspect strainer to be

sure it is clean.

2. Connect foot valve and strainer to the first length of suction pipe

and lower pipe into the well. Add sections of pipe as needed, using

PTFE pip thread sealant tape on all male threads.

• To prevent sand and sediment from entering the system,

the foot valve/strainer should be at least 5 feet above the

bottom of the well.

• Additionally, the foot valve/strainer should be installed 10 to

20 feet below the lowest level to which water will drop while

operating (pumping water level). Your well driller can furnish

that information.

3. When the proper depth is reached, install a sanitary well seal over

the pipe and in the well casing. Tighten the bolts to seal the casing.

4. Be sure the entire run of suction pipe is leakproof so pump does

not lose prime and fail to work. Never install a suction pipe that is

smaller than the suction port of the pump.

5. When using a foot valve, a priming tee and plug are recommended

(Figure 1).

Suction

pipe

Foot

Valve

Priming plug

Priming tee

Drawdown water

level (pump on)

10-20' (3-6 m)

20' (6 m)

max.

At least 5 feet

(1.5 m)

828 1011

Standing water

level (pump off)

DUG WELL INSTALLATION

Use the same procedures as Cased Well installation.

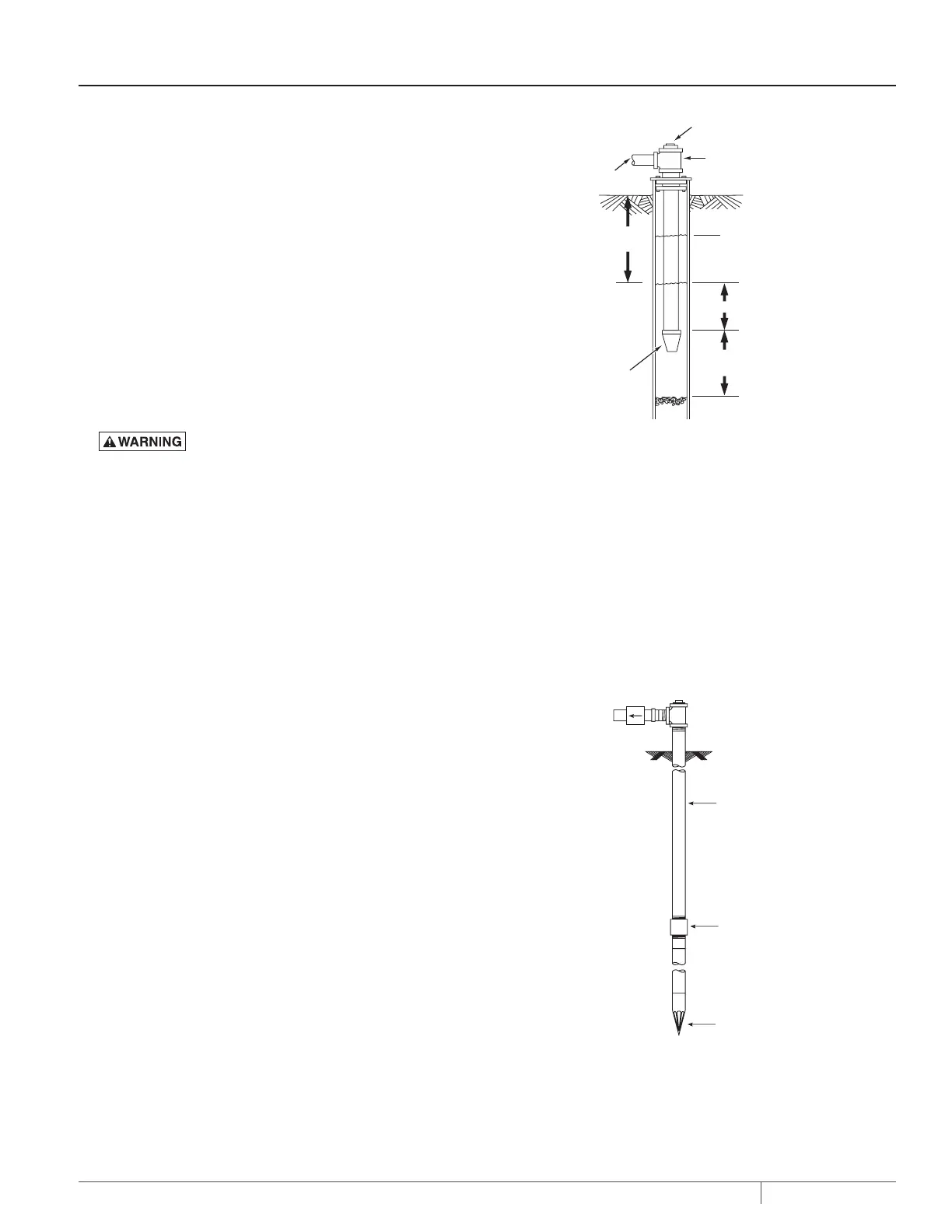

DRIVEN POINT INSTALLATION

1. Connect the suction pipe to the drive point (Figure 2). Keep

horizontal pipe run as short as possible. Use PTFE pip thread

sealant tape on male pipe threads. Multiple well points may be

necessary to provide sufficient water to pump.

2. Install a check valve in horizontal piping (Figure 2). Ensure check

valve flow arrow points toward the pump.

3. Never install a suction pipe that is smaller than the suction port of

the pump.

Check valve

Steel drive pipe

Drive coupling

Driven point

Figure 1: Cased/Dug Well Installation

Figure 2: Driven Point Installation

Loading...

Loading...