8

S536 (11-25-19)

OPERATIONS/MAINTENANCE

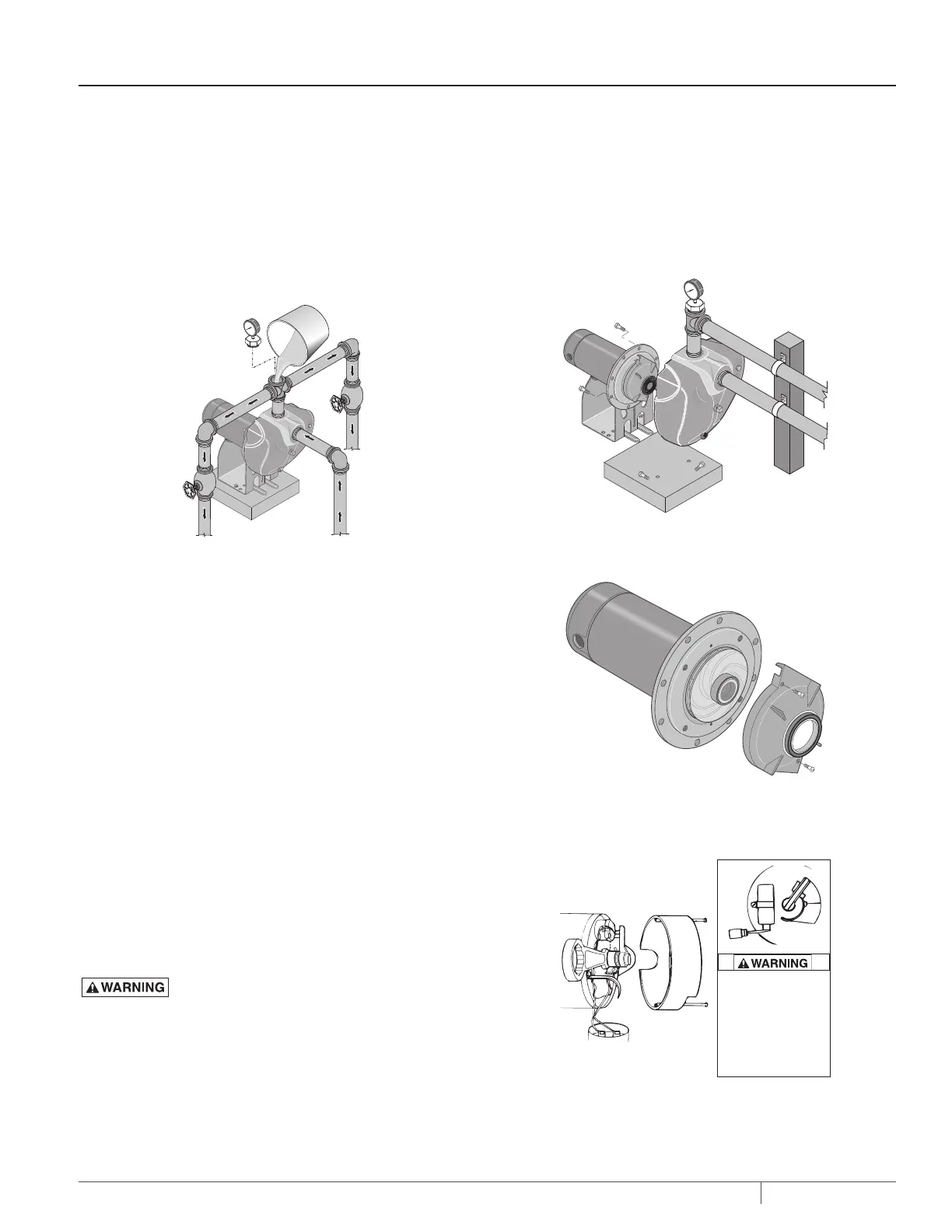

PRIMING THE PUMP

‘Priming’ refers to the pump expelling all air in the system and

beginning to move water from its source out into the system. It does

not refer only to pouring water into the pump (although pouring water

in is usually the first step).

NEVER run pump dry. Running pump without adequate water will

damage seals and can melt impeller and diffuser. To prevent damage,

fill pump with water before starting.

1. Remove priming plug (Figure 9).

20

100

80

60

40

2. Make sure suction and discharge valves and any hoses on

discharge side of pump are open.

3. Fill pump and suction pipe with water.

NOTICE: If a priming tee and plug have been provided for a long

horizontal run, be sure to fill suction pipe through this tee and

replace plug. (Do not forget to PTFE pipe thread sealant tape the

plug.)

4. Replace priming plug, using PTFE pipe thread sealant tape on

thread, and tighten plug.

5. Start pump. Water should be produced within 10 minutes,

depending on depth of water (not more than 20’) and length of

horizontal run (10’ of horizontal suction pipe = 1’ of vertical lift due

to friction losses in the pipe).

If no water is produced within 10 minutes:

• Stop pump

• Release all pressure

• Remove priming plug

• Refill and try again.

Hazardous pressure and risk of ex plo sion and

scalding. If pump is run con ti nu ously at no flow (that is, with discharge

shut off or without priming), water may boil in pump and piping

system. Under steam pressure, pipes may rupture, blow off of fittings

or blow out of pump ports and scald anyone near.

To prevent explosion, do the following:

A. Be sure discharge (valve, pistol grip hose nozzle, etc.) is open

whenever pump is running.

B. When priming, monitor pump and piping tempera ture. If pump or

piping begin to feel warm to the touch, shut off pump and allow

system to cool off. Release all pressure in system and refill pump

and piping with cold water.

C. If pump fails to produce water when attempting to prime, release

all pressure, drain pump and refill with cold water after every two

attempts.

20

100

80

60

40

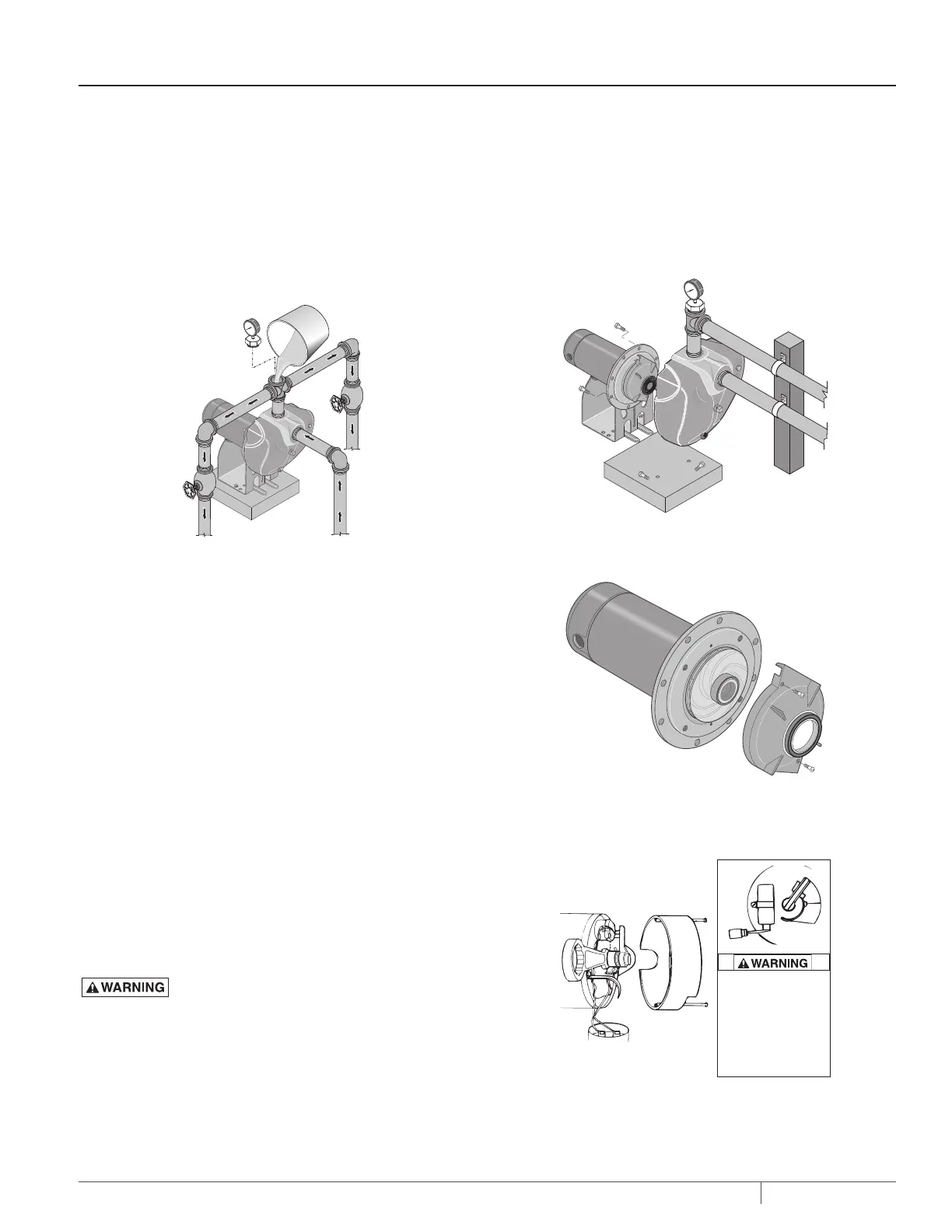

To avoid electrical

shock hazard, use

insulated-handle

screwdriver to short

capacitor terminals

as shown.

Figure 10: Slide Motor

Figure 11: Remove Diffuser

Figure 12: Hold Shaft

Figure 9: Remove Priming Plug and Fill Pump Before

Starting

Loading...

Loading...