Maintenance 10

Seal Removal

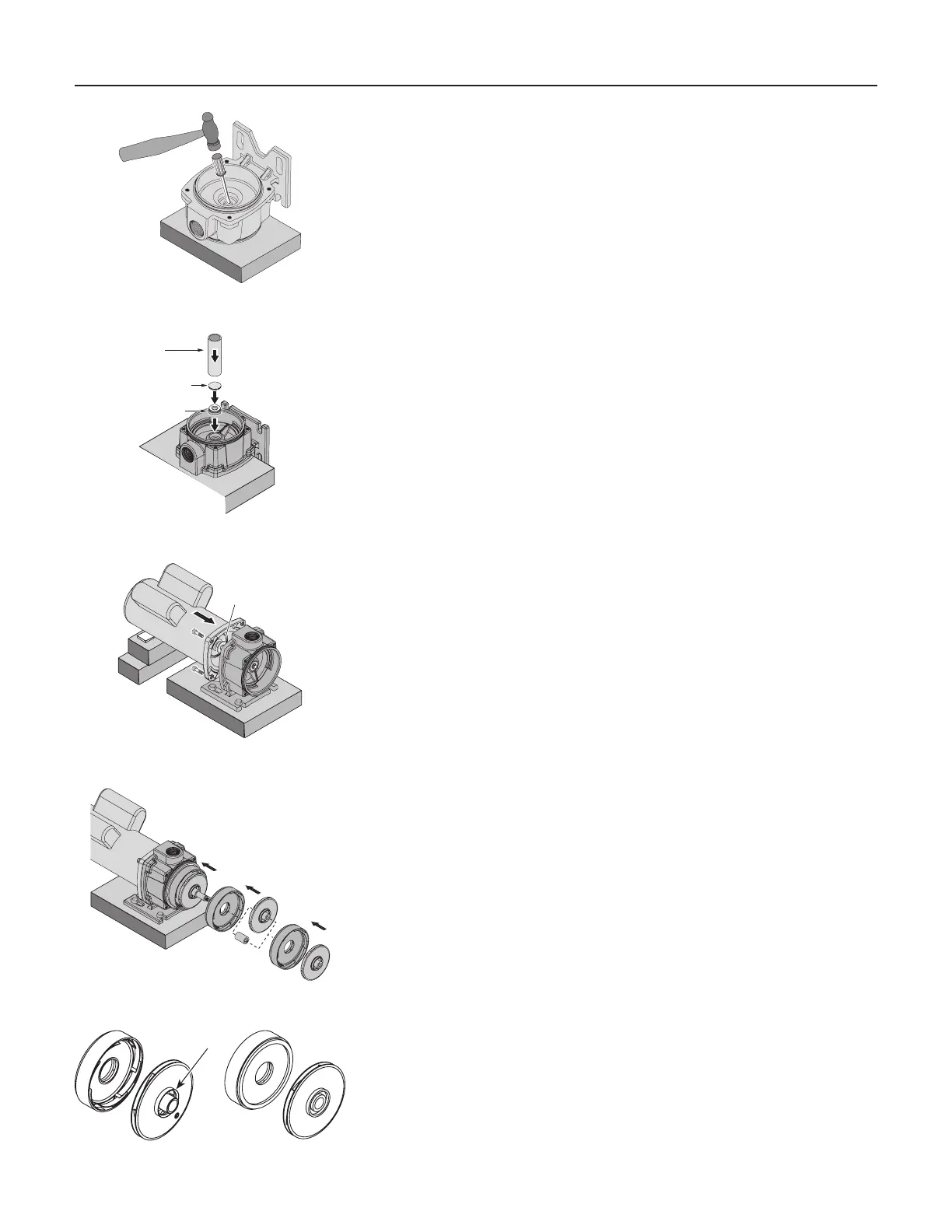

1. Followtheinstructionsunder“PumpDisassembly”,above.

2. Removethedischargepipefromthebracket(Ref.No.4).

3. Remove the hold down bolts from the bracket.

4. Turn the bracket motor side up on the bench and use a screwdriver to

carefully tap the stationary seal half out of the bracket (see Figure 21).

5. Clean the seal seat cavity in the bracket.

Seal Installation

1. Turnthebracketpumpsideuponthebench.Youwillneedtoblockit

up to do this (See Figure 22).

2. Clean the seal cavity in the bracket.

3. Wet the outer edge of the rubber cup on the ceramic seat with liquid

soap.Besparing!

4. Put a clean cardboard washer on the seal face. With thumb pressure,

press the ceramic seal half firmly and squarely into the seal cavity.

The polished face of the ceramic seat is up. If the seal will not seat

correctly, remove it, placing the seal face up on the bench. Reclean the

cavity. The seal should now seat correctly.

5. If the seal does not seat correctly after recleaning the cavity, place a

clean cardboard washer over the polished seal face and carefully press

itintoplaceusingapieceofstandard3/4”pipeasapress.

NOTICE:Besureyoudonotscratchthesealface.

6. Dispose of the cardboard washer and recheck the seal face to be sure it

is free of dirt, foreign particles, scratches and grease.

7. Inspect the shaft to be sure it is free of nicks and scratches.

Pump Reassembly

1. Boltthebracketdowntothefoundation(seeFigure23).

2. Slide the motor shaft through the seal and bolt up the motor (see

Figure23).Makesurethattheslingerisontheshaftbetweenthe

bracketandthemotorflange.Makesurethatyoudon’tchiptheseal

face with the shaft shoulders and that the shaft does not take the weight

of the motor at any time.

2. CAREFULLYslidetherotatingsealhalfontotheshaft,sealfacefirst.

Makesurethatyoudon’tchipthesealfaceontheshaftshoulders.

3. Followthesealhalfwiththespacer(Ref.No.7).Slidethewasherup

against the seal.

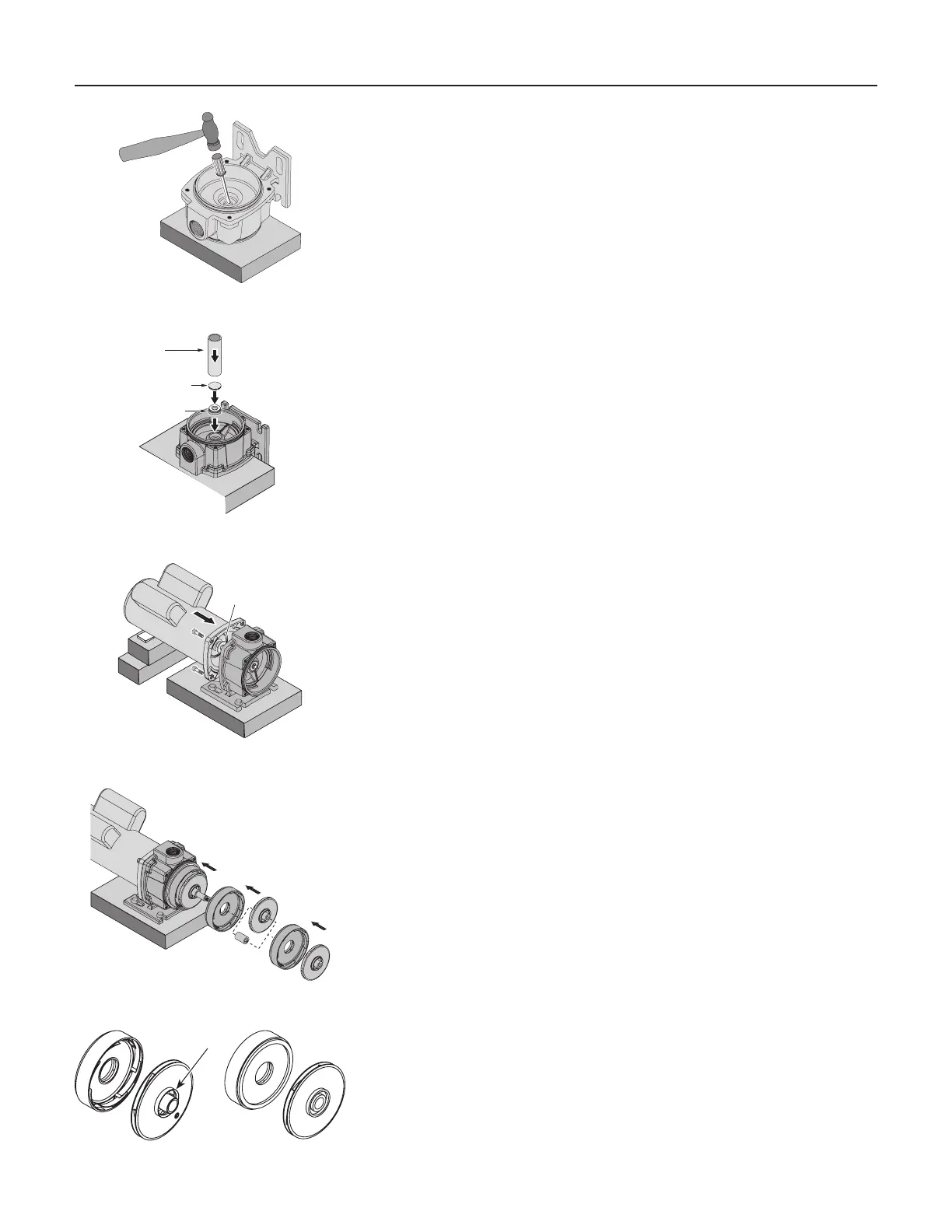

4. Slide a diffuser onto the shaft (open face out) until it seats on the

bracket (see Figure 24). Follow the diffuser with an impeller on a four-

stage pump or with the stainless steel spacer if a three-stage pump.

Engagethemoldedimpellerkeyintheslotintheshaft.Don’tforceit!

Besurethattheimpellereye,withmetalring,facesout(forward-see

Figure 25).

5. Repeat step 4 with the remaining impellers and diffusers.

6. Reinstall the toothed washer, the flat washer, and the impeller nut (in

thatorder–Ref.Nos.12,13,14)ontothemotorshaft(seeFigure26).

Holdtheshaftandtightentheimpellernutto10ft.-lbs.torque.

7. CheckthesleeveO-Rings;iftheyshowanydamageorwear,replace

them.ReinstallthesleeveO-Rings(Ref.No.8)onthebracketandthe

suction body.

Figure 24

Pipe

Cardboard

Washer

Seal Half

Figure 22

Slinger

Figure 23

Figure 21

Figure 25

Correct orientation Incorrect orientation

Metal ring

Loading...

Loading...