Installation 6

Pump Installation

Makesurethatallpipejointsinthesuctionpipeareairtightaswellas

water tight. If the suction pipe can suck air, the pump will not be able to

pull water from the well.

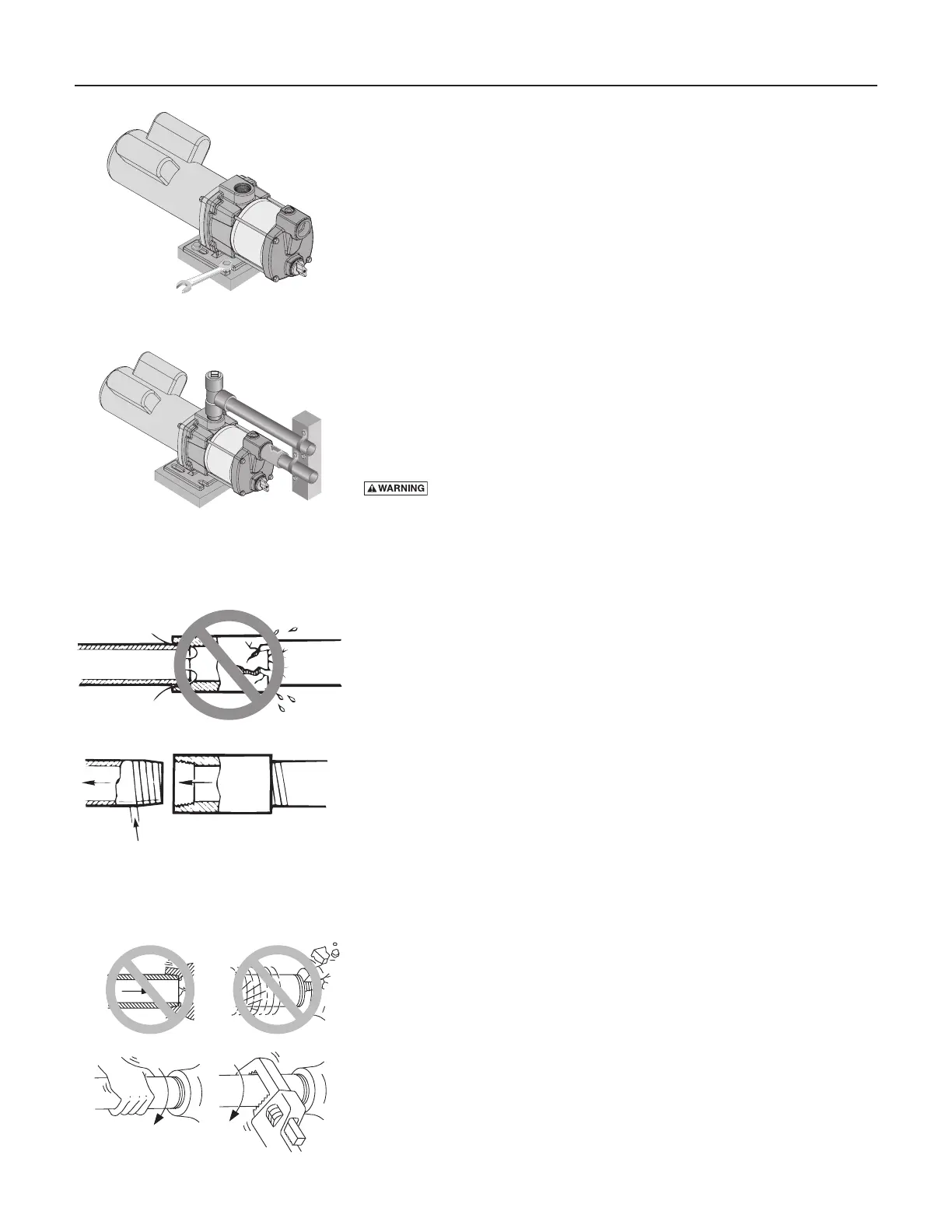

1 Boltpumptosolid,levelfoundation.

2. Support all piping connected to the pump.

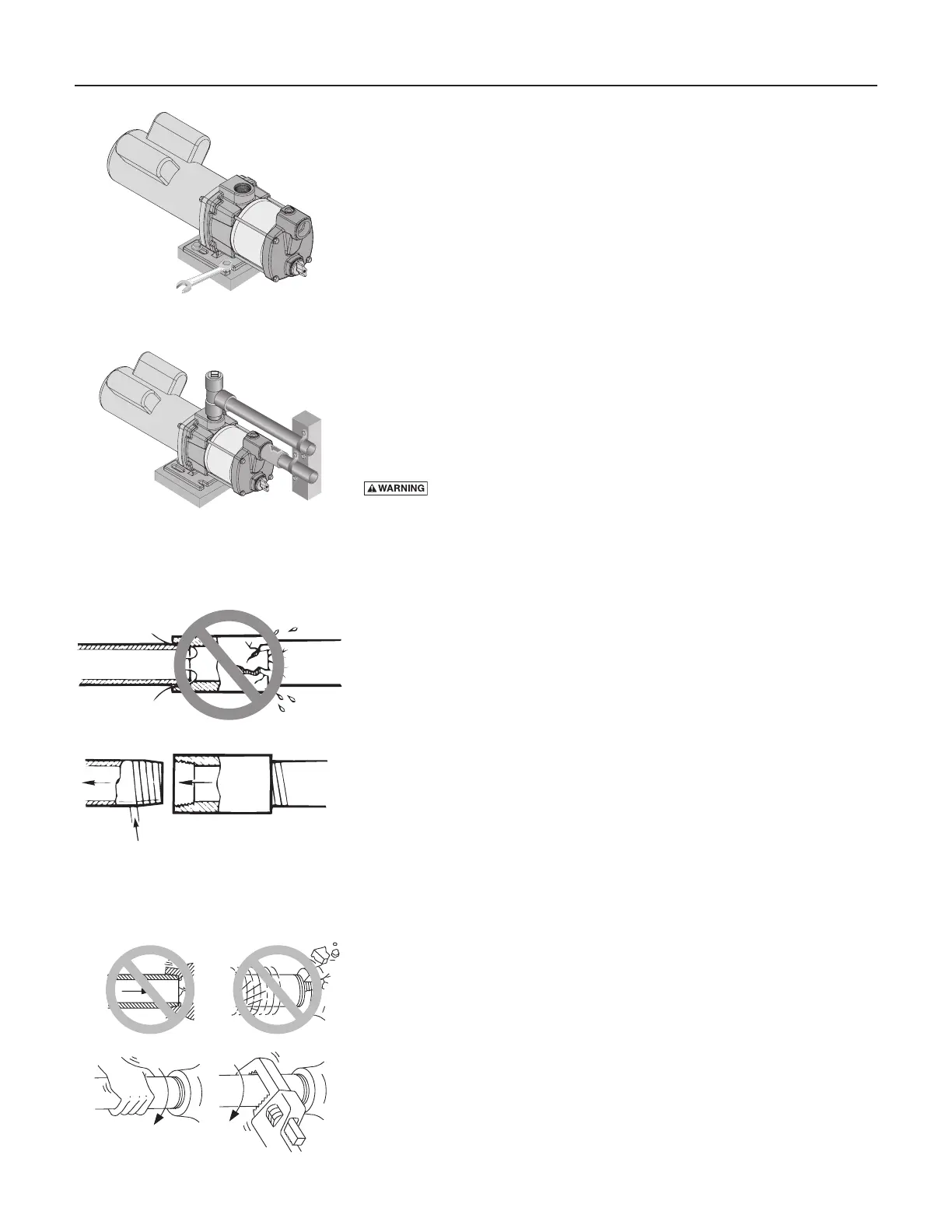

3. Wrap1-1/2totwolayersofPTFEtapeclockwise(asyoufaceendof

pipe) on all male threads being attached to pump.

4. Tighten joints hand tight plus 1-1/2 turns. Do not overtighten.

NOTICE : Installpumpasclosetowellheadaspossible.Longpipingruns

and many fittings create friction and reduce flow.

NOTICE: For long horizontal pipe runs, install a priming tee between check

valve and well head as shown in Figure 6. For driven point installations,

installacheckvalveasshowninFigure6.Besurecheckvalveflowarrow

points toward pump.

Useschedule80orironpipe.SeeWell Pipe In stalla tion for more

information.

Wiring

Hazardous voltage. Follow these rules to avoid potential harm:

• Groundmotorbeforeconnectingtoelectricalpowersupply.Failureto

ground motor can cause severe or fatal electrical shock hazard.

• Donotgroundtoagassupplyline.

• Toavoiddangerousorfatalelectricalshock,turnOFFpowertomotor

before working on electrical connections.

• Supplyvoltagemustbewithin±10%ofnameplatevoltage.Incorrect

voltage can cause fire or damage motor and voids warranty. If in doubt

consult a licensed electrician.

• UsewiresizespecifiedinWiring Chart. If possible, connect pump to a

separate branch circuit with no other appliances on it.

• Wiremotorasshown(Figure12B).Ifmotornameplatediagramdoes

notmatcheitherFigure12Aor12B,follownameplatediagram.

Figure 8 – Bolt Pump Down

Figure 9 – Independently Support All

Piping Attached to Pump

Figure 10 – Use PTFE pipe thread

sealant tape on pipe joints and

connections to pump.

Suction pipe.

If air flows

water won’t

Use PTFE tape.

Use PTFE pipe thread sealant tape or pipe joint

compound approved for use on PVC.

Figure 11 – Don’t overtighten.

Don’t Hit

Thread Stops

Overtighten

From

Well

Pump

Body

Hand Tight Plus 1-1/2 Tu rns With Wrench.

Loading...

Loading...