Installation 5

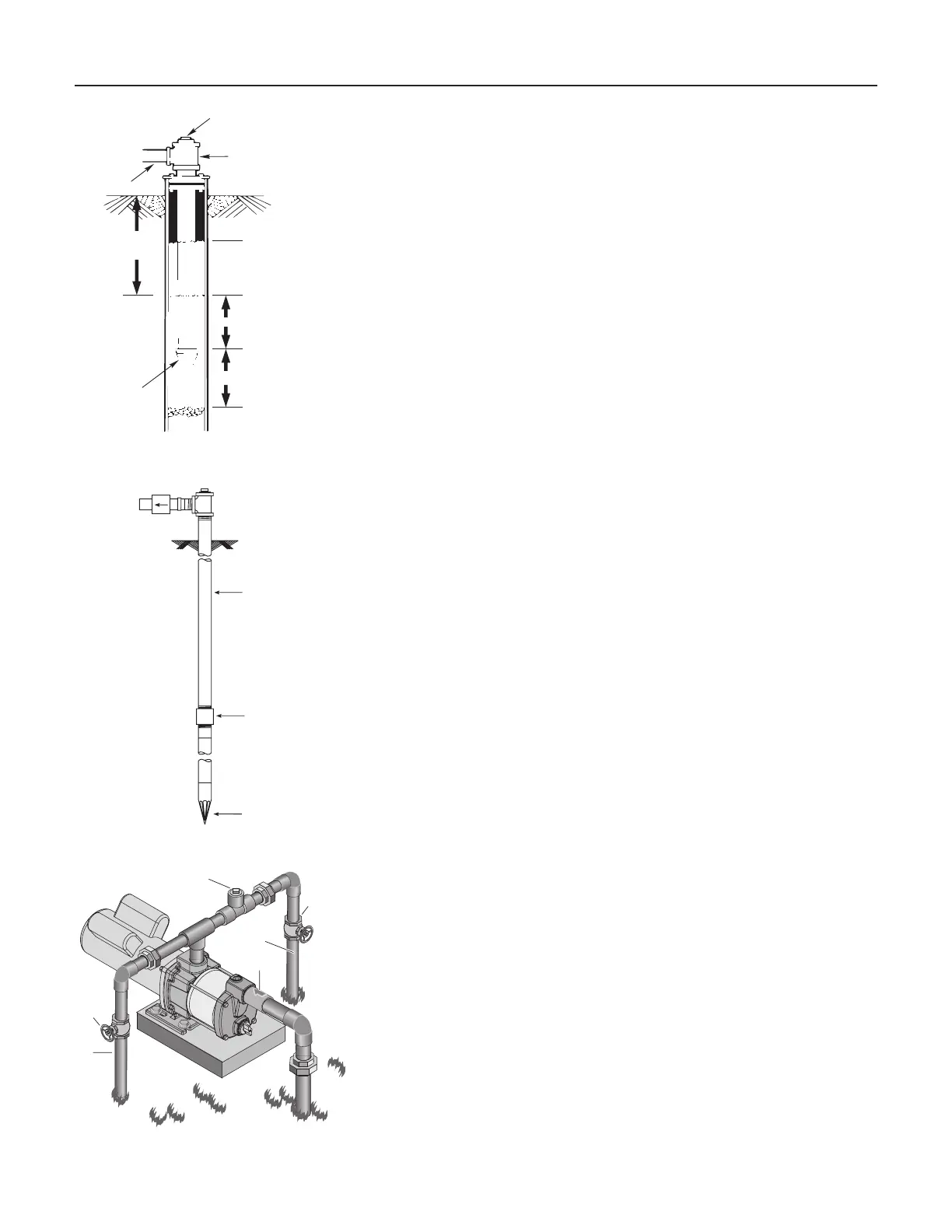

Cased Well Installation

1. Inspect foot valve to be sure it works freely. Inspect strainer to be sure it

is clean.

2. Connect foot valve and strainer to the first length of suction pipe and

lowerpipeintowell.Addsectionsofpipeasneeded,usingPTFEtape

onmalethreads.Besurethatallsuctionpipeisleakprooforpump

will lose prime and fail to pump. Install foot valve 10 to 20 feet below

the lowest level to which water will drop while pump is operating

(pumpingwaterlevel).Yourwelldrillercanfurnishthisinformation.

3. To prevent sand and sediment from entering the pumping system, the

foot valve/strainer should be at least 5 feet above the bottom of the well.

4. When the proper depth is reached, install a sanitary well seal over the

pipe and in the well casing. Tighten the bolts to seal the casing.

5. When using a foot valve, a priming tee and plug as shown in Figure 5

are recommended.

Dug Well Installation

Same as cased well installation.

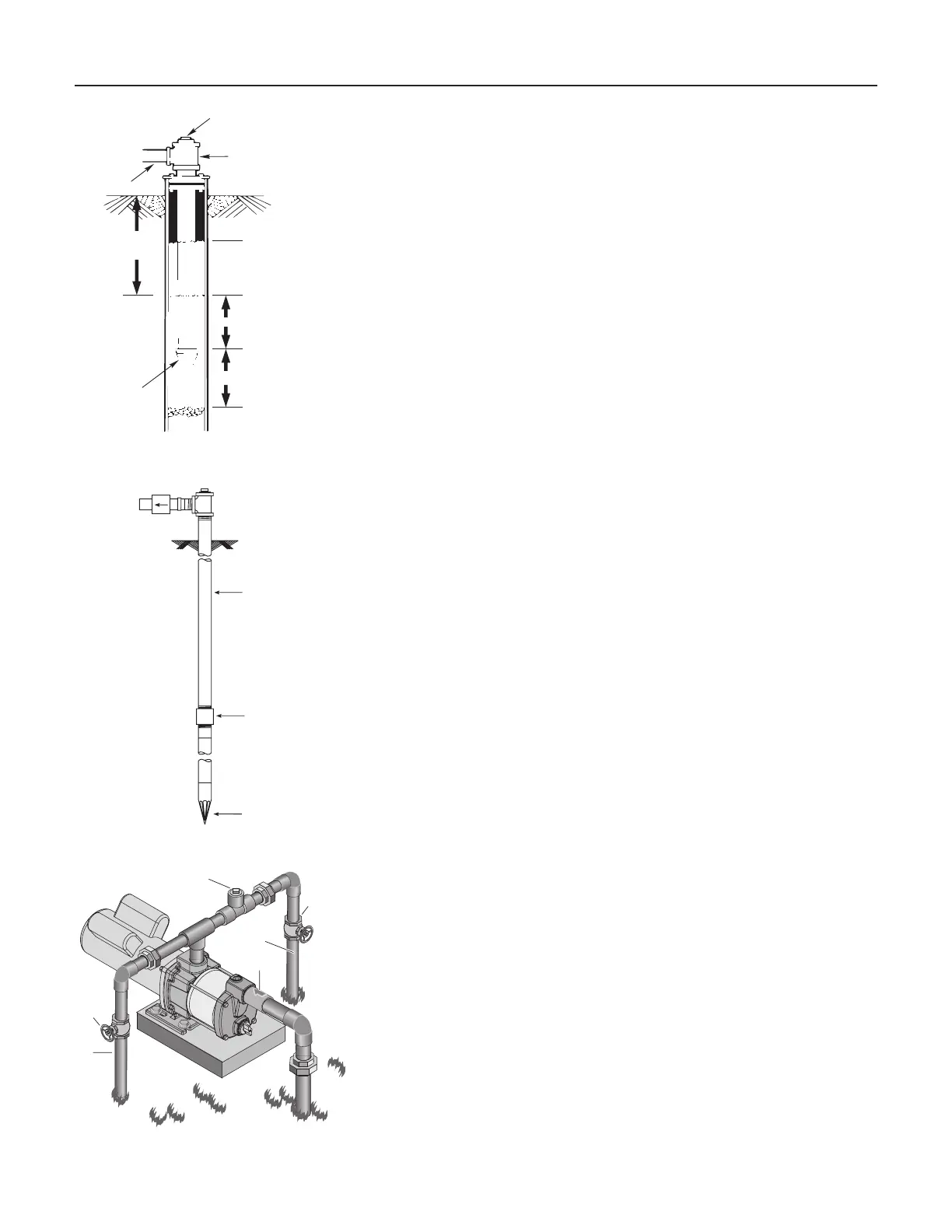

Driven Point Installation

1. Connect the suction pipe to the drive point as illustrated in Figure6.

Keephorizontalpiperunasshortaspossible.UsePTFEpipethread

sealanttapeonmalepipethreads.Multiplewellpointsmaybe

necessary to provide sufficient water to pump.

2. Install a check valve in horizontal pipe. Flow arrow on check valve

must point toward pump.

Horizontal Piping From Well To Pump

1. Neverinstallasuctionpipethatissmallerthanthesuctionportof

thepump.

2. To aid priming on well point installations, install a line check valve as

showninFigure6.Besurecheckvalveflowarrowpointstowardpump.

Discharge Pipe Sizes

1. If increasing discharge pipe size, install reducer in pump discharge port.

Do not increase pipe size by stages.

2. When the pump is set away from the points of water use, the discharge

pipe size should be increased to reduce pressure losses caused

byfriction.

• Upto100’run:Samesizeaspumpdischargeport.

• 100’to300’run:Increaseonepipesize.

• 300’to600’run:Increasetwopipesizes.

Sprinkling Application

This pump is de signed to deliver plenty of water at full sprinkler pres sure. It can

pump from a pond, cistern or well points.

Pump discharge can be divided to supply two (2) or more sprinkler systems.

A suggested multiple dis charge to service is shown in Figure 7.

Do not use in a pressure tank or booster pump application.

Figure 5 – Cased/Dug Well Installation

Suction

pipe

Foot

Valve

Priming tee

Standing water

level (pump off)

Drawdown water

level (pump on)

10-20' (3-6 m)

20' (6 m) max.

At least 5 feet (1.5 m)

Figure 6 – Driven Point Installation

Check valve

Steel drive pipe

Drive coupling

Driven point

Figure 7 – Multiple Discharge

4326 0203

Gate

Valve

Gate

Valve

To

Service

To

Service

Plug

Check

Valve

Loading...

Loading...