Maintenance • Troubleshooting 11

Troubleshooting

Symptom Possible Cause(s) Corrective Action(s)

Motorwillnotrun

Disconnect switch is off Besureswitchison.

Fuse is blown or circuit breaker

tripped.

Replace fuse or reset circuit breaker.

Starting switch is defective. DISCONNECTPOWER;Replacestartingswitch.

Wires at motor are loose,

disconnected, or wired incorrectly.

Refertoinstructionsonwiring.DISCONNECTPOWER;checkandtightenallwiring.

Risk of electrical shock. Capacitor voltage may be hazardous. To

dischargecapacitor,holdinsulatedhandlescrewdriverBYTHEHANDLEandshort

capacitor terminals together. Do not touch metal screwdriver blade or capacitor

terminals. If in doubt, consult a qualified electrician.

Motorrunshotandoverloadkicks

off.

Motoriswiredincorrectly. Refer to instructions on wiring.

Voltageistoolow

Check with power company. Install heavier wiring if wire size is too small (See

Electrical/WiringChart).

Motorrunsbutnowaterisdelivered

in new installation:*

1. Improper priming 1. Re-prime according to instructions.

2. Air leaks 2. Check all connections on suction line, with soapy water or shaving cream.

3.Leakingfootvalveorcheck

valve

3. Replace foot valve or check valve.

Pump has lost prime in installation

already in use:

1. Air leaks 1. Check all connections on suction line and shaft seal.

2. Water level below suction pipe

inlet

2.Lowersuctionlineintowaterandre-prime.Ifrecedingwaterlevelinwellexceeds

20’(6.1M),adeepwellpumpisneeded.

Foot valve or strainer is plugged Clean foot valvye or strainer.

Impeller is plugged Clean impeller.

Check valve or foot valve is stuck

shut

Replace check valve or foot valve.

Pipes are frozen Thawpipes.Burypipesbelowfrostline.Heatpitorpumphouse.

Foot valve and/or strainer are

buried in sand or mud.

Raise foot valve and/or strainer above bottom of water source. Clean foot valve and

strainer.

Water level is too low for shallow

well setup to deliver water.

Pumpwillnotliftwatermorethan20’(6.1M).

Pump does not deliver water to full

capacity.

Water level in well is lower than

estimated.

Adeepwelljetwillbeneededifdepthtowaterinyourwellismorethan20’

(6.1m).

Steel piping (if used) is corroded

or limed, causing excess friction.

Replace with plastic pipe where possible, otherwise with new steel pipe.

Piping is too small in size Uselargerpiping.

Packed well point Backflushwellpointorsinknewpoint.

*Stoppump;thencheckprime

before looking for other causes.

Unscrewprimingplugandseeif

water is in priming hole.

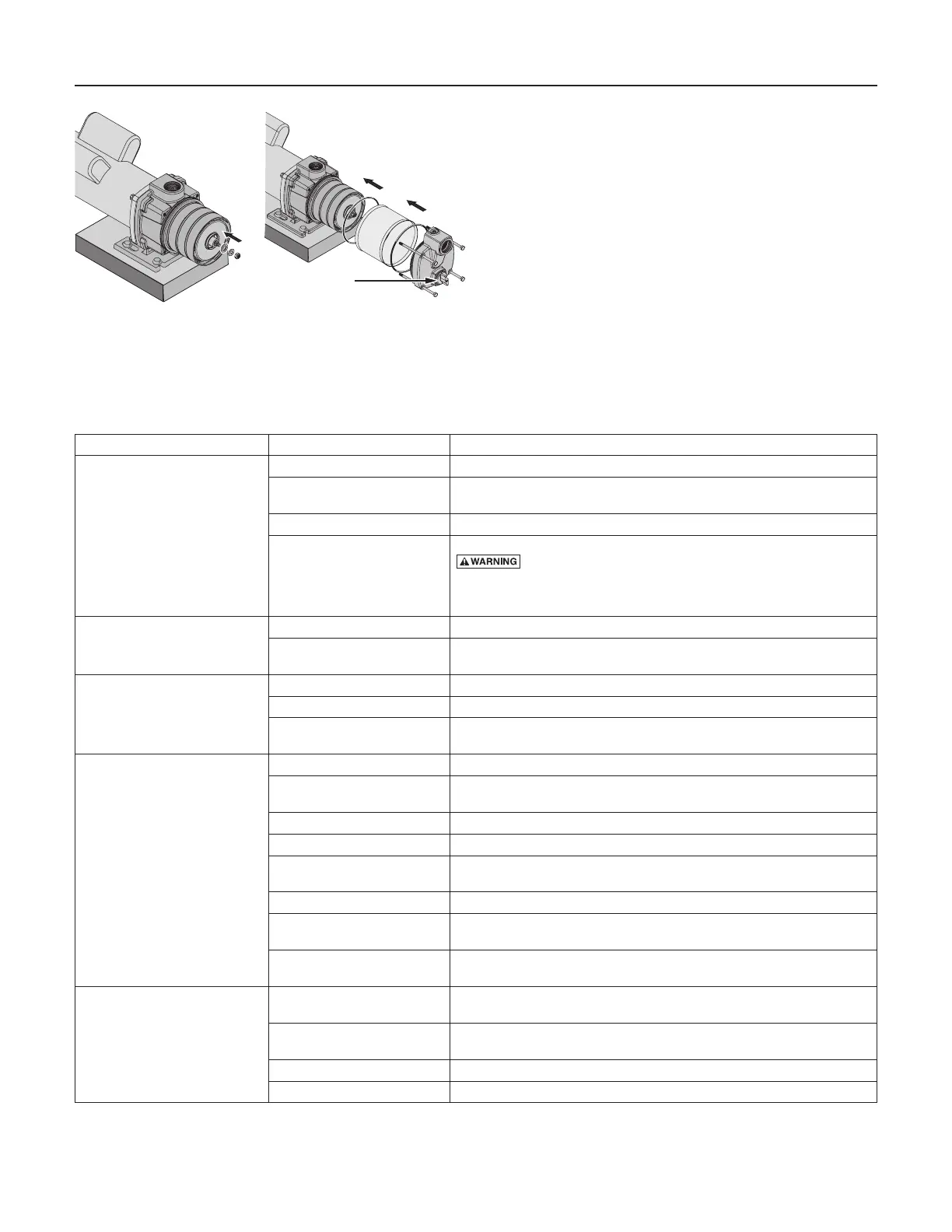

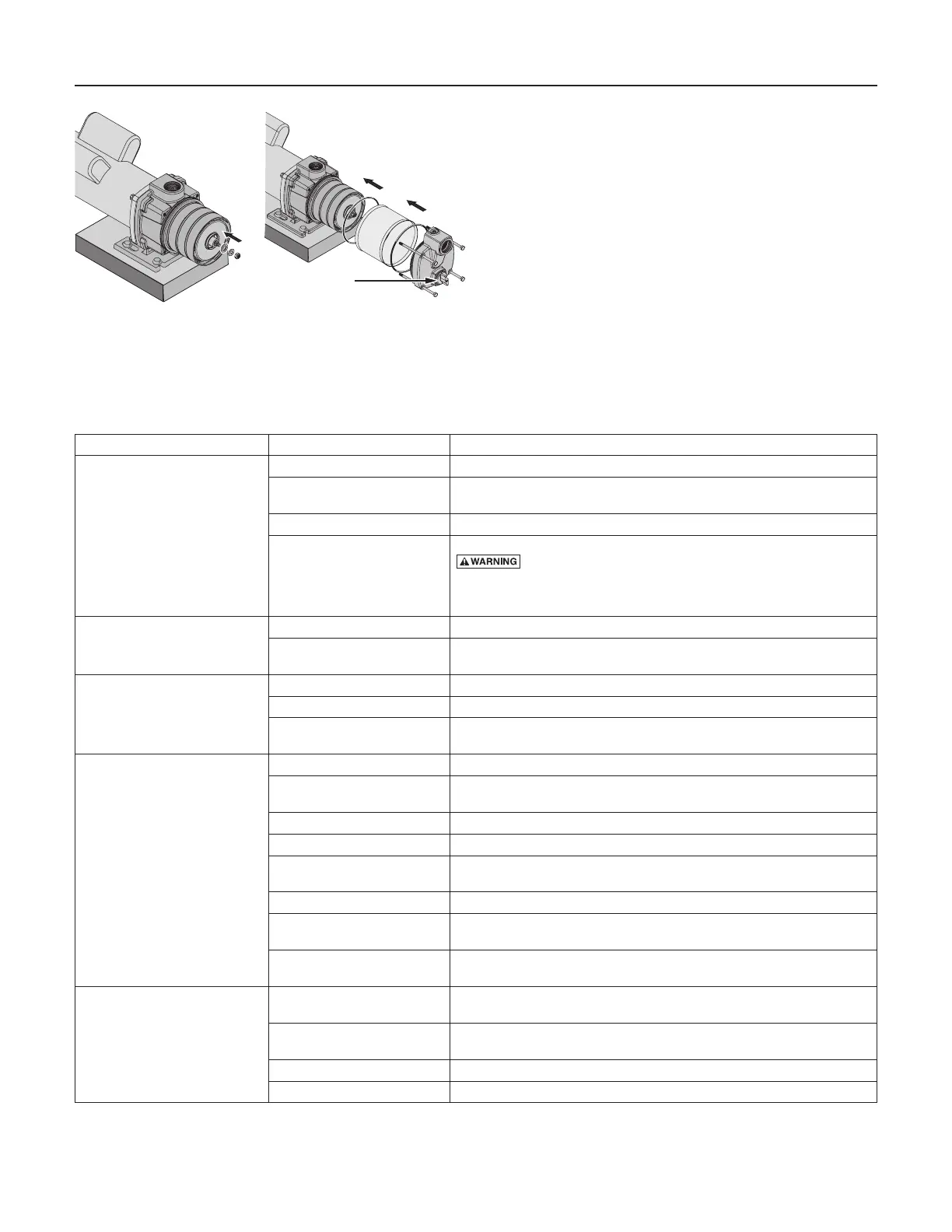

8. Reinstall the sleeve on the bracket and the pump

suctionbodyinthesleeve.Besurethatyoudonot

pinch or damage the O-Ring. See Figure27.

9. Installfourcapscrews(Ref.No.18)throughthe

pump head and into the bracket. Tighten the

capscrews to 22ft.-lbs. torque.

10. Reinstallthedrainplugandwasher(Ref.Nos.17

and 16) in the suction body.

NOTICE: Do not disturb the recirculation valve.

11. Reinstall the suction and discharge piping and open

all valves. Check for leaks.

12. Prime the pump according to the instructions on

Page 8.

Recirculation Valve

Do not disturb!

Figure 27

Figure 26

Loading...

Loading...