8

PM-727MV v6 2020-10

Copyright © 2020 Quality Machine Tools, LLC

The power lamp should light.

4. Check the emergency function by pressing the E-

Stop button. The power lamp should go out, de-en-

ergizing the contactor circuit, disabling all electrics.

5. Restore power by twisting the E-Stop button rmly

clockwise.

Test run procedure

DO NOT LEAVE THE MACHINE UNATTENDED DUR-

ING THIS PROCEDURE

1. Gear levers set to L and 1 (115 rpm)? Gears fully

engaged? Speed control fully counter clockwise,

PM-727V only.

2. Test the spindle motor by pressing the Left and Right

motor switches in turn.

3. Run the spindle at 115 rpm for a few minutes, then

stop.

4. Select each of the available speeds in turn (L-2, L-3,

H-1, etc.). Check gear engagement each time, then

run for a few minutes.

The machine should now be ready for normal opera-

tions.

Optional

After a few hours of run time you may wish to drain the

gearbox to ush out any residue from the manufacturing

process. Rell the gearbox with the oil recommended in

Section 4.

Allow the spindle to stop com-

pletely before shifting gears

If this doesn’t happen, the E-stop func-

tion is defective, and needs attention

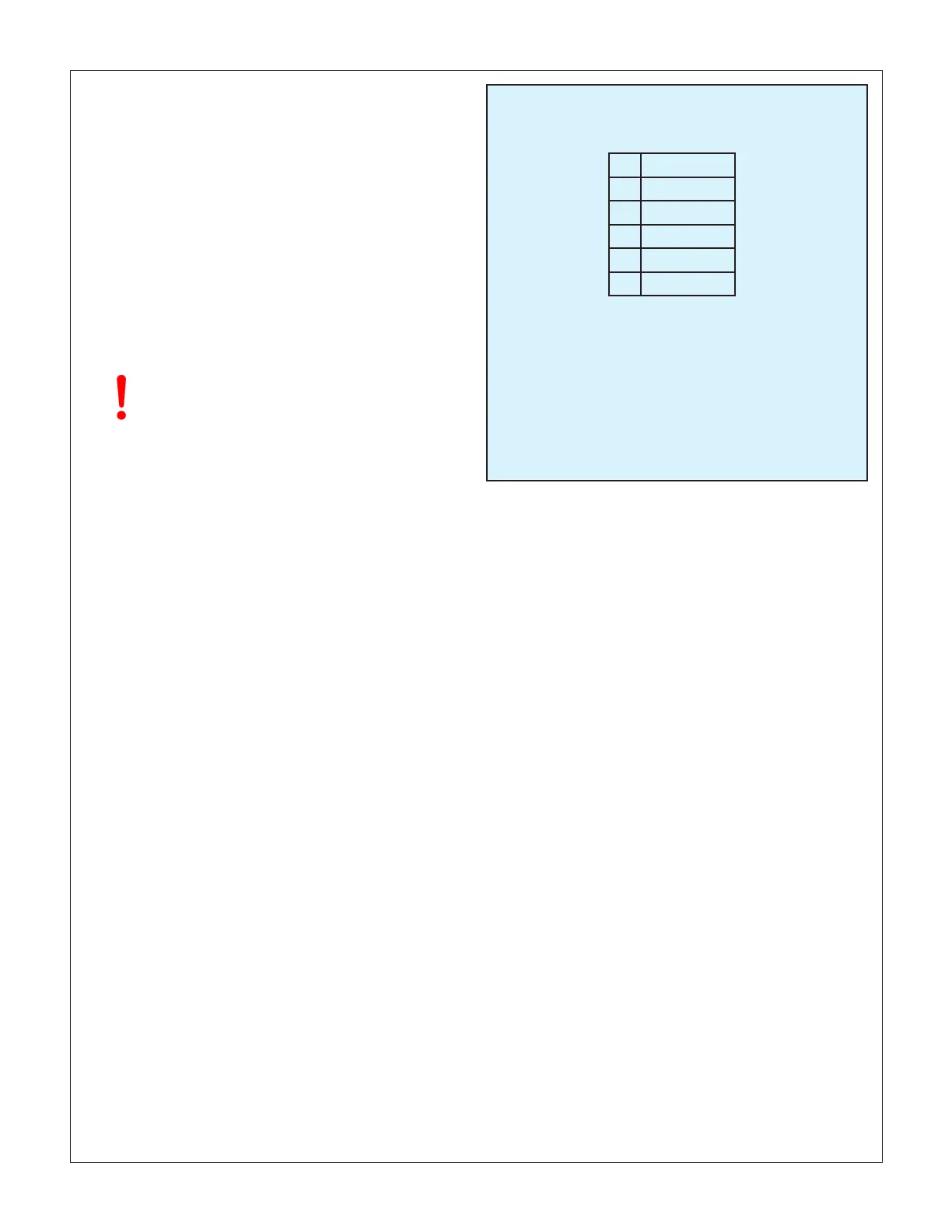

SPEED RANGES (rpm)

L1 40-190

L2 180-380

L3 350-560

H1 550-1000

H2 980-1860

H3 1800-3000

PM-727V USERS PLEASE NOTE ...

Not shown in Section 5:

• Spindle speed is transmitted to the tachom-

eter on the control panel by a sensor locat-

ed adjacent to spindle.

• The electrical schematic does not show the

PM-727V variable speed drive. This replac-

es entirely the motor and motor witching

circuit shown in the schematic.

Loading...

Loading...