10

PM-727MV v6 2020-10

Copyright © 2020 Quality Machine Tools, LLC

MOVING THE TABLE

Left-right movement of the table is usually said to be

on the X-axis (a.k.a. “longitudinal travel” or “traversing”).

Front-back movement is on the Y-axis, sometimes called

“cross travel”.

Each axis has a leadscrew with handwheel and gradu-

ated dial with 0.001” divisions, 0.1” per revolution, Fig-

ure 3-3. If the mill is not equipped with digital readouts

(DROs), the table can be accurately positioned by count-

ing whole turns and divisions, keeping leadscrew back-

lash in mind. This means that table motion must always

be in the same direction up to the point of reference,

then on to the desired location, see “Spindle Positioning

by Counting Divisions” later in this section.

Replace the drawbar cap to

protect bearings and spline

Figure 3-3 Y-axis handwheel, X-axis clamp levers

Figure 3-4 Y-axis clamp levers

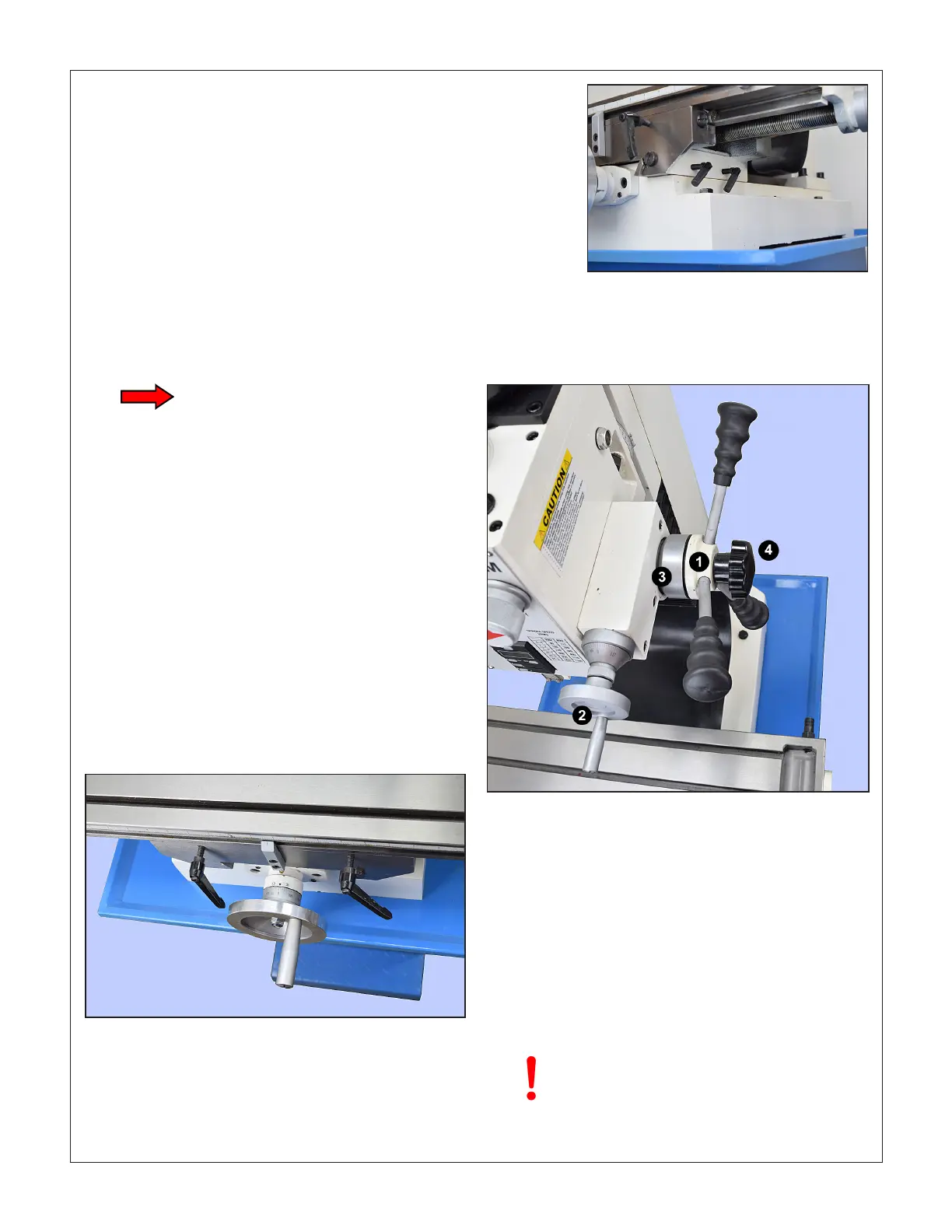

QUILL DOWNFEED

The quill is controlled in two dierent ways, coarse and

ne.

In the drilling mode, coarse feed, the mill functions like a

standard drill press – pull the upper lever toward you to

lower the quill. For milling operations the 3-lever hub is

disengaged, and the quill is controlled by the ne down-

feed handwheel. The quill is locked by a lever on the left

of the headstock, Figure 3-1.

Figure 3-5 Quill downfeed controls

The quill pinion is driven by the lever hub (1). The ne con-

trol handwheel (2) is connected by a worm gear to sleeve (3),

which is free to rotate — doing nothing to the quill — if it is not

meshed with the lever hub. Do this by tightening knob (4).

Always lock the quill when milling

splined spindle. Fully tighten the drawbar.

To remove: Protect the table under the spindle with

rags or scrap wood. Loosen the drawbar one half turn

or less — holding the spindle with a wrench if necessary

— then tap the top of the drawbar with a brass or dead-

blow hammer to unseat the taper. Unscrew the drawbar

with one hand while supporting the R-8 device with the

other hand.

Why support the R-8 item? Because the table, vises

and workpiece can be damaged by falling tools and drill

chucks. The cutting tool itself can also be damaged in

the same way.

Loading...

Loading...