Page 59 of 69

Proton Products InteliSENS DG2030 Diameter Gauge Instruction Manual (Issue 1a)

MODBUS PARAMETER ACCESS PROTOCOL

This protocol provides access to individual parameters or blocks of parameters and is typically used in

a production environment where the Proton Products instrument is connected to a computer, Modbus

connected PLC or similar device.

The parameters consist of 16-bit words (DW) and are divided into input and output groups:

• Input parameters may be read from and written to and are used to configure the instrument.

• Output parameters are read only and provide access to instrument status and measurement

data.

1 word (DW) consists of 2 bytes

1 byte consists of 8 bits

4 bits are expressed by 1 hexadecimal digit (0-9, A-F)

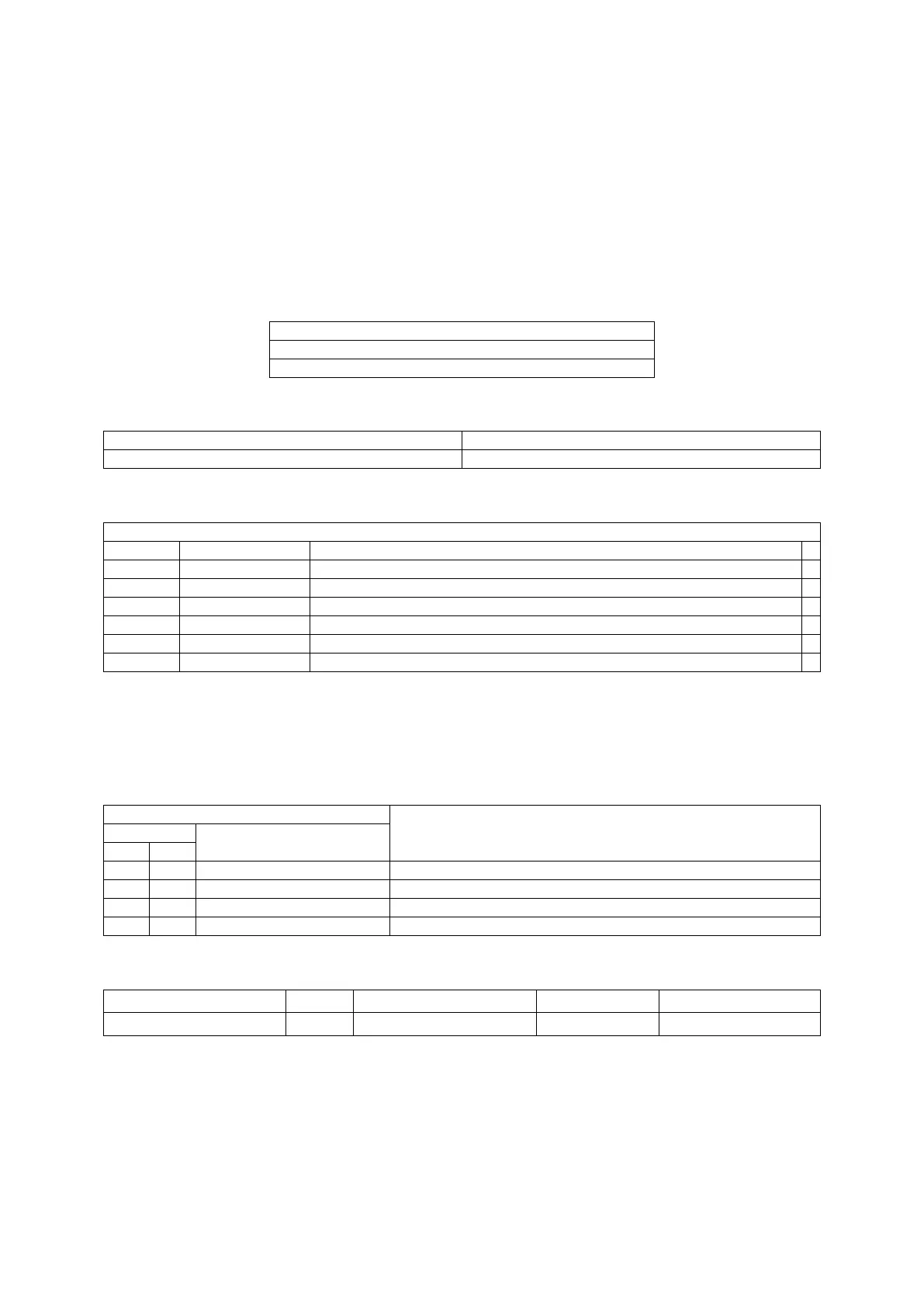

Proton Products instruments use the following Modbus format:

RTU (Remote Terminal Unit)

CRC (Cyclic Redundancy Check)

The Modbus RTU frame format is as follows:

>3.5 characters of silence

Slave (instrument) Modbus address

Modbus function code determines read or write operation

Length and data dependent on function

Cyclic Redundancy Check for errors (not required for Modbus TCP)

+

>3.5 characters of silence

+

Please refer to Modbus Protocol Standards documentation for the CRC error check field calculation. For Modbus protocol

communications over TCP/IP networks via the Ethernet port (also known as Modbus TCP), the CRC error check field is not

required as error checking is handled by the TCP/IP protocol.

For brevity, only the fields marked * are shown in the subsequent examples.

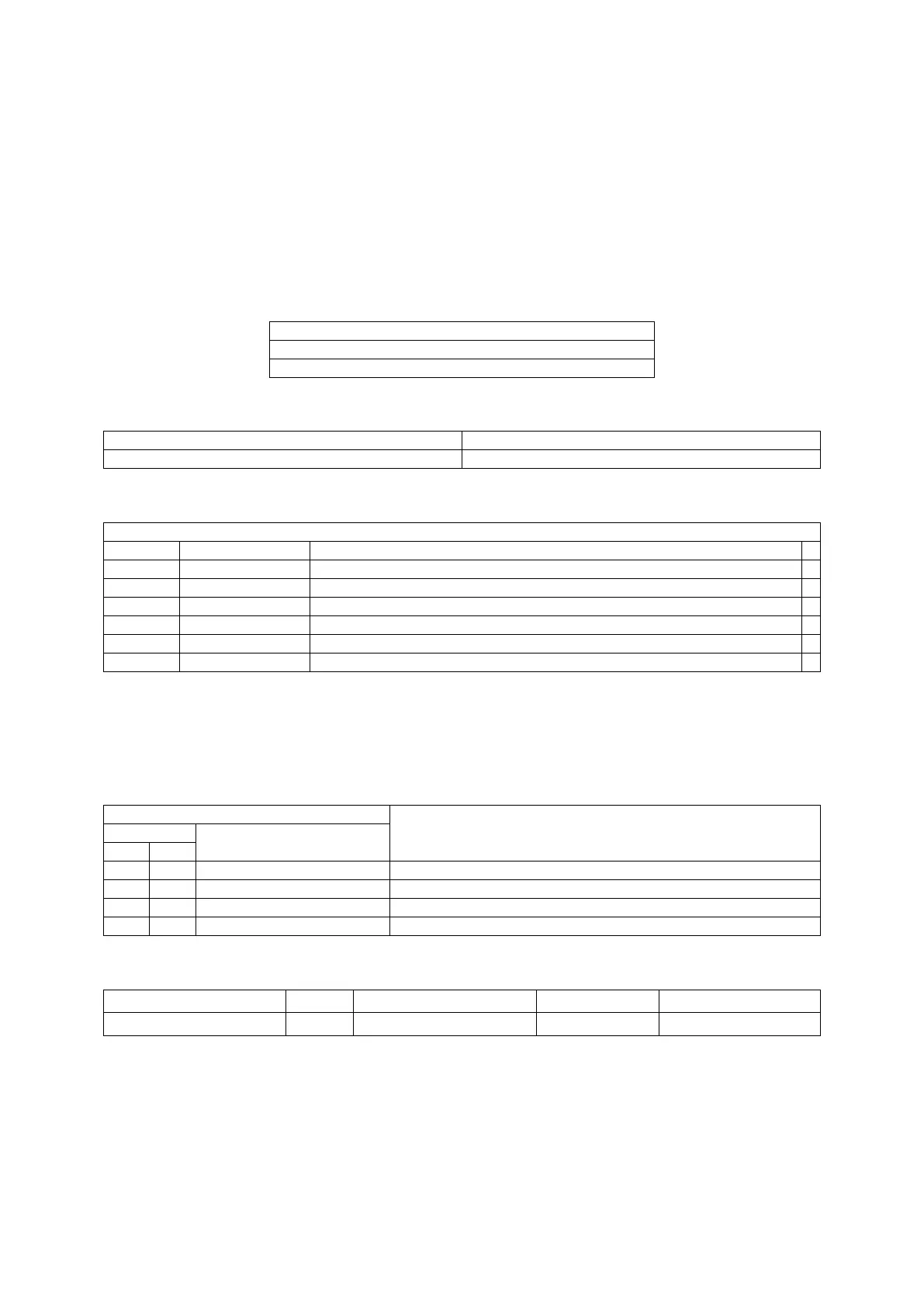

Proton Products instruments support the following Modbus functions:

Instrument operation

Name

Read data from a block of consecutive input parameters.

Write data to a single input parameter.

Preset Multiple Registers

Write data to a block of consecutive input parameters.

Read data from a block of consecutive output parameters.

For Modbus protocol communications via the RS-232 serial port, the RS-232 data format is:

Loading...

Loading...