Fluid Scavenging System

Fluid from the separator element is returned to the inlet

valve byway of a scavenger tube positioned on the

outside of the fluid separator element, through an

orifice contained in a fitting mounted on the side of the

air/fluid reservoir. A nylon scavenge tube then carries

the oil to the compressor.

Cleaning of the orifice should be performed, whichever

comes first of the following conditions:

● When no fluid is seen moving through the nylon

scavenging tube.

● When excessive fluid carryover is detected.

● Every separator change.

“Twice per year.

NOTE: Do not ream the orifice or change the orifice

size.

Control Line Air Filter

Condensate collection in the bowl must be drained.

The control line filtration uses the float method of

automatic drain. Function of this automatic drain

should be observed daily for operation and immediate

repairs made if the filter should corrode.

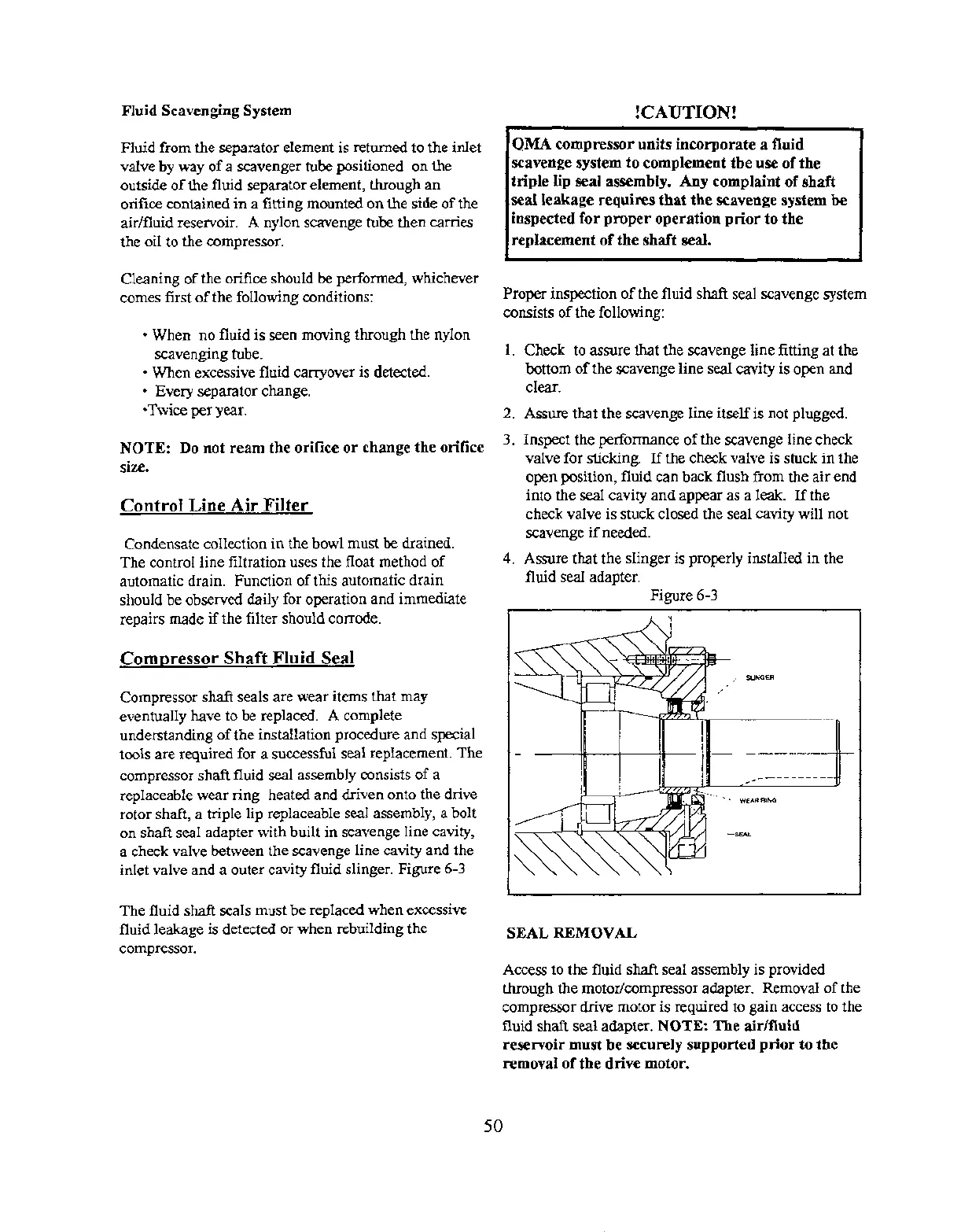

Compressor Shaft Fluid Seal

Compressor shaft seals are wear items that may

eventually have to be replaced. A complete

understanding of the installation procedure and special

tools are required for a successful seal replacement. The

compressor shaft fluid seal assembly consists of a

replaceable wear ring heated and driven onto the drive

rotor shaft, a triple lip replaceable seal assembly, a bolt

on shaft seal adapter with built in scavenge line cavity,

a check valve between the scavenge line cavity and the

inlet valve and a outer cavity fluid slinger. Figure 6-3

The fluid shaft seals must be replaced when excessive

fluid leakage is detected or when rebuilding the

compressor.

!CAUTION!

QMA compressor units incorporate a fluid

scavenge system to complement the use of the

triple lip seal assembIy. Any complaint of shaft

.waIleakage requires that the scavenge system be

inspected for proper operation prior to the

replacement of the shaft seal.

Proper inspection of the fluid shaft seal scavenge system

consists of the following:

1.

2.

3.

4.

Check to assure that the scavenge line fitting at the

bottom of the scavenge line seal cavity is open and

clear.

Assure that the scavenge line itself is not plugged.

Inspect the performance of the scavenge line check

valve for sticking. If the check valve is stuck in the

open position, fluid can back flush from the air end

into tie seal cavity and appear as a leak. If the

check valve is stuck closed the seal cavity will not

scavenge if needed.

Assure that the slinger is properly installed in the

fluid seal adapter. - - -

Figure 6-3

SEAL REMOVAL

Access to the fluid shaft seal assembly is provided

through the motor/compressor adapter. Removal of the

compressor drive motor is required to gain access to the

fluid shaft seal adapter. NOTE: The air/fluid

reservoir must be securely supported prior to the

removal of the drive motor.

50

Loading...

Loading...