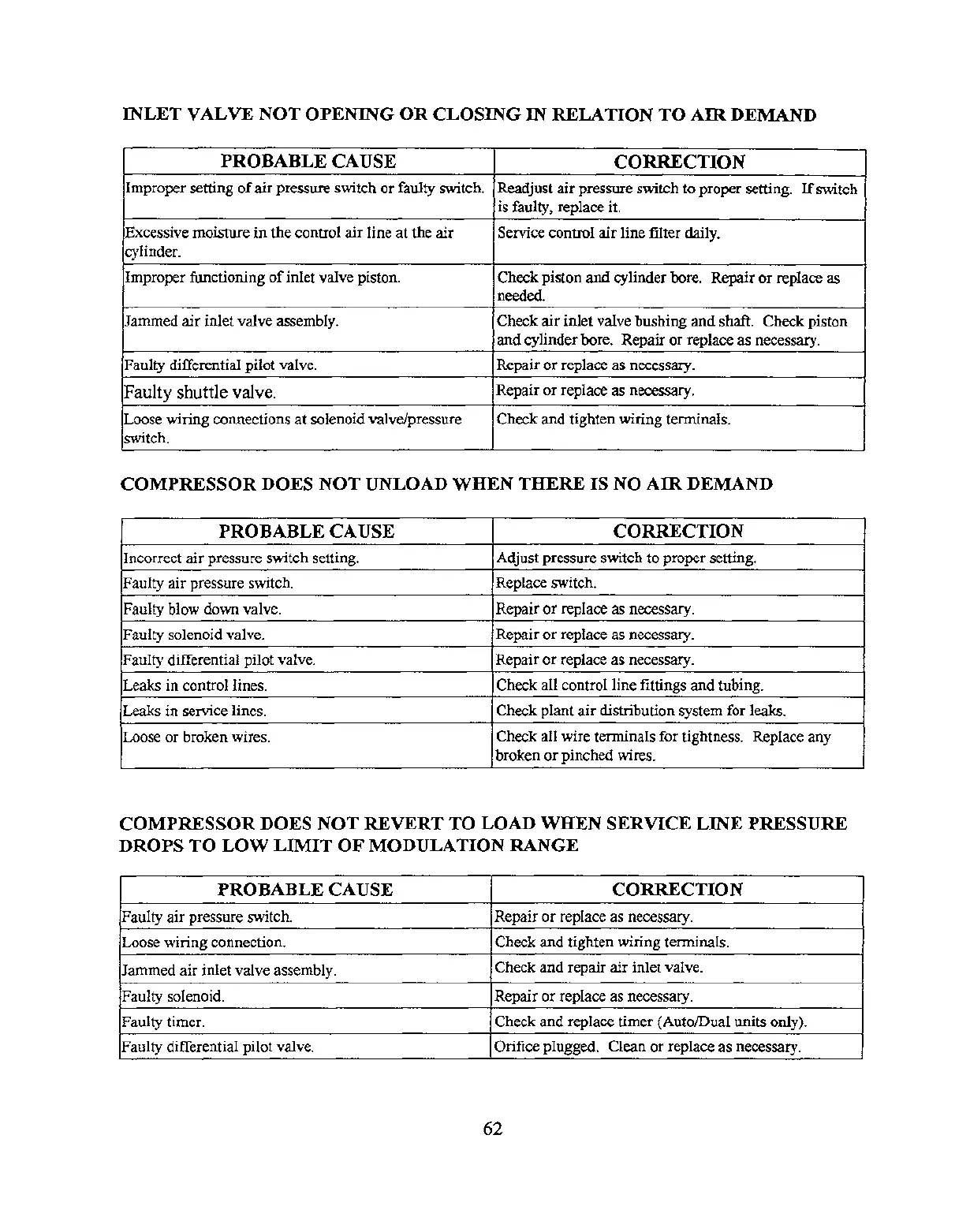

INLET VALVE NOT OPENING OR CLOSING IN RELATION TO AIR DEMAND

PROBABLE CAUSE

CORRECTION

Improper setting of air pressure switch or faulty switch.

Readjust air pressure switch to proper setting. If switch

is faulty, replace it.

Excessive moisture in the control air line at the air

Service control air line filter daily.

cylinder.

Improper functioning of inlet valve piston.

Check piston and cylinder bore. Repair or replace as

needed.

Jammed air inlet valve assembly. Check air inlet valve bushing and shaft. Check piston

and cylinder bore. Repair or replace as necessmy.

Faulty differential pilot valve.

Repair or replace as necessary.

]Faultv shuttle valve.

lRepairorreplace as necessary.

I

Loose wiring connections at solenoid valve/pressure Check and tighten wiring terminals.

switch.

I

COMPRESSOR DOES NOT UNLOAD WHEN THERE IS NO AIR DEMAND

PROBABLE CAUSE CORRECTION

Incorrect air pressure switch setting.

Adjust pressure switch to proper setting.

Faulty air pressure switch.

Replace switch.

Faulty blow down valve.

Repair or replace as necessary.

Faulty solenoid valve.

Repair or replace as necessary.

Faulty differential pilot valve.

Repair or replace as necessa~.

Leaks in control lines. Check all control line fittings and tubing.

lLeaks in service lines. ICheck plant air distribution system for leaks.

Loose or broken wires.

Check all wire terminals for tightness. Replace any

broken or pinched wires.

COMPRESSOR DOES NOT REVERT TO LOAD WHEN SERVICE LINE PRESSURE

DROPS TO LOW LIMIT OF MODULATION RANGE

I

PROBABLE CAUSE

I

CORRECTION

I

Faulty air pressure switch.

lRepair or replace as necessary.

Loose wiring connection.

Check and tighten wiring terminals.

Jammed air inlet valve assembly.

Check and repair air inlet valve.

Faulty solenoid.

Repair or replace as necessary.

Faulty timer. Check and replace timer (Auto/Dual units only).

Faulty differential pilot valve. Orifice plugged. Clean or replace as necessary.

J

,..,,,..,, .,, ,L,, ,,a.... “.. ,, L. LA..-, v

62

,- ---- , -.. ~..-.,”-- “ ,. . . . . . .

Loading...

Loading...