.“

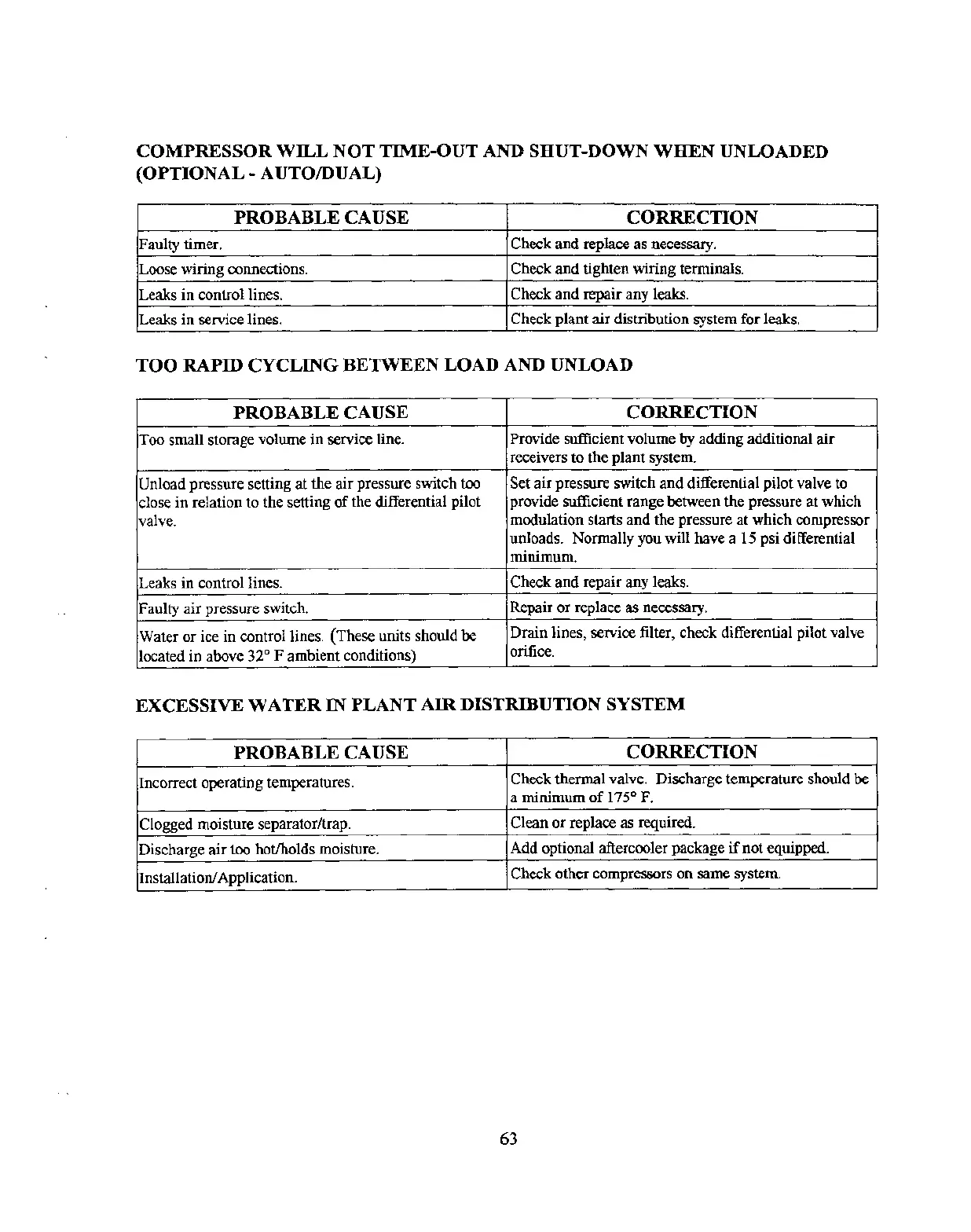

COMPRESSOR WILL NOT TIME-OUT AND SHUT-DOWN WHEN UNLOADED

(OPTIONAL - AUTO/DUAL)

PROBABLE CAUSE

CORRECTION

Faulty timer.

Check and replace as necessary.

Loose wiring connections.

Check and tighten wiring terminals.

Leaks in control lines.

Check and repair any leaks.

Leaks in service lines.

Check plant air distribution system for leaks.

TOO RAPID CYCLING BETWEEN LOAD AND UNLOAD

PROBABLE CAUSE

CORRECTION

Too small storage volume in service line.

Provide suftlcient volume by adding additional air

receivers to the plant system.

Unload pressure setting at the air pressure switch too

Set air pressure switch and differential pilot valve to

close in relation to the setting of the differential pilot

provide suftlcient range between the pressure at which

valve.

modulation starts and the pressure at which compressor

unloads. Normally you will have a 15 psi differential

minimum.

Leaks in control lines.

Check and repair any leaks.

Faulty air pressure switch.

Repair or replace as necessmy.

Water or ice in control lines. (These units should be

Drain lines, service filter, check differential pilot valve

Ilocated in above 32° F ambient conditions)

Ioritice.

EXCESSIVE WATER IN PLANT AIR DISTRIBUTION SYSTEM

I

PROBABLE CAUSE

CORRECTION

Incorrect operating temperatures.

Check thermal valve. Discharge temperature should be

a minimum of 175° F.

Clogged moisture separatorhrap.

Clean or replace as required.

Discharge air too hot/holds moisture.

Add optional aftercooler package if not equipped.

Installation/Application.

Check other compressors on same system.

63

Loading...

Loading...