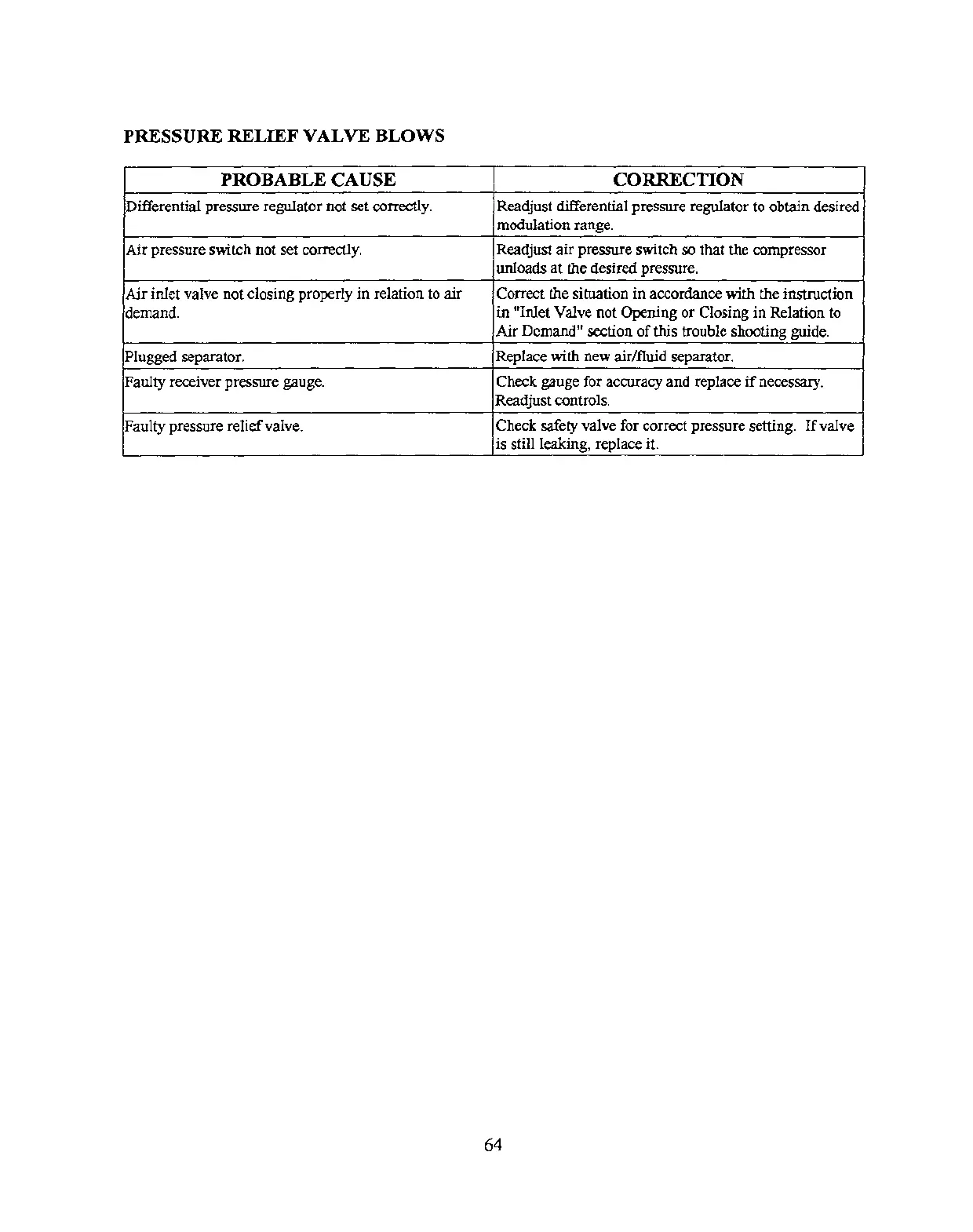

PRESSURE RELIEF VALVE BLOWS

PROBABLE CAUSE

Differential pressure regulator not set correctly.

Air pressure switch not set correctly.

Air inlet valve not closing properly in relation to air

demand.

Plugged separator.

Faulty receiver pressure gauge.

Faulty pressure relief valve.

CORRECTION

Readjust differential pressure regulator to obtain desired

modulation ramze.

Readjust air pressure switch so that the compressor

unloads at the desired pressure.

Correct the situation in accordance with the instruction

in “Inlet Valve not Opening or Closing in Relation to

Air Demand” section of this trouble shooting guide.

Replace with new air/fluid separator.

Check gauge for accuracy and replace if necessary.

Readjust controls.

Check safety valve for correct pressure setting. If valve

is still leakimz redate it.

64

r–

r——-

Loading...

Loading...