RG27/35/37 Operation • Service • Maintenance

800.392.2686

41

Maintenance

Grease / Oil Build-Up - Remove

Wipe all fittings, caps, and plugs before servicing.

Keep a close watch for leaks. If leaking is observed, find the

source, and correct the leak.

Check the fluid levels more frequently than the recom mend-

ed periods if leaking is suspected or ob served, until the

problem is corrected.

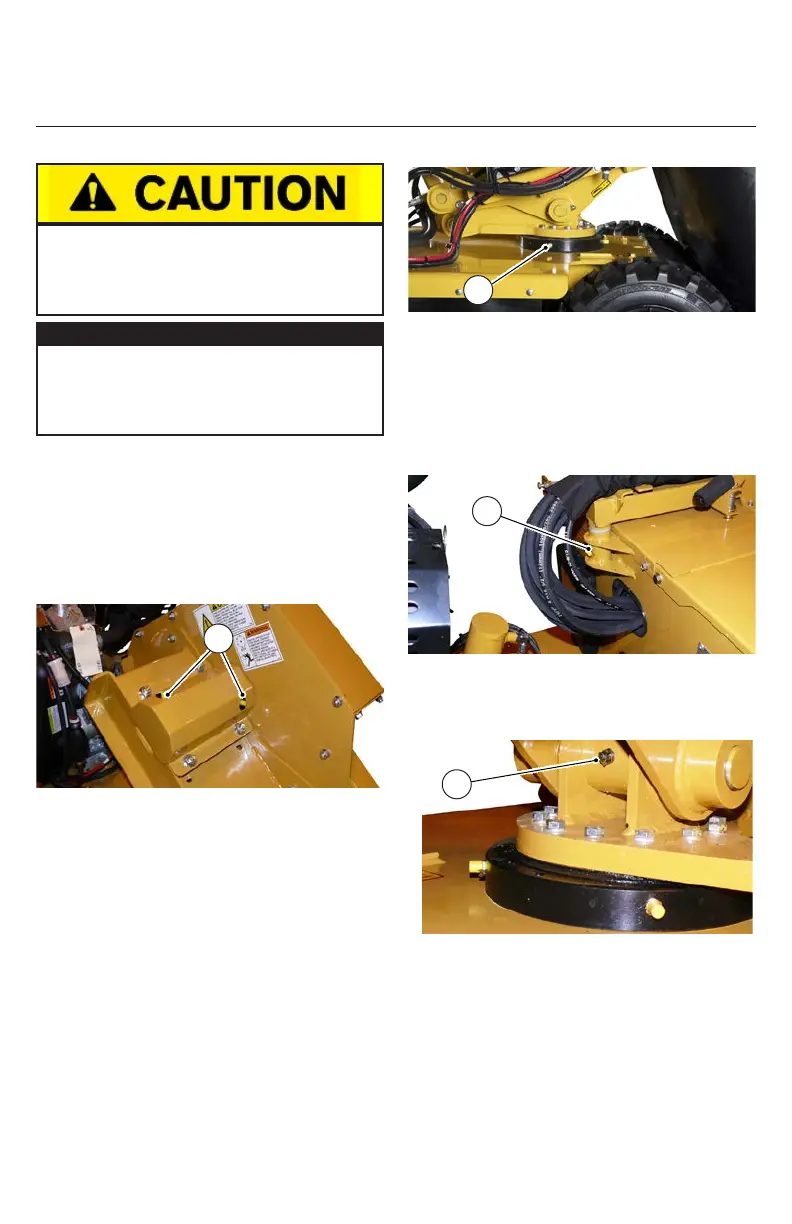

Jackshaft Bearings - Lubricate the Fittings

Lubricate the two fittings (2) (one on each jackshaft bearing)

3-4 pumps. Note: cover can be removed to ensure bearings

are adequately greased.

Wheel Hub Bearings - Inspect & Grease

The wheel bearings on the ma chine are sealed and generally

do not require service. They are, however, greasable. Locate

the zerk on the inside of the wheel assembly. Apply 3-4

pumps of grease.

If abnormal wear or other damage seems present, replace

bearings immediately. Worn or frozen bearings can damage

the drive components

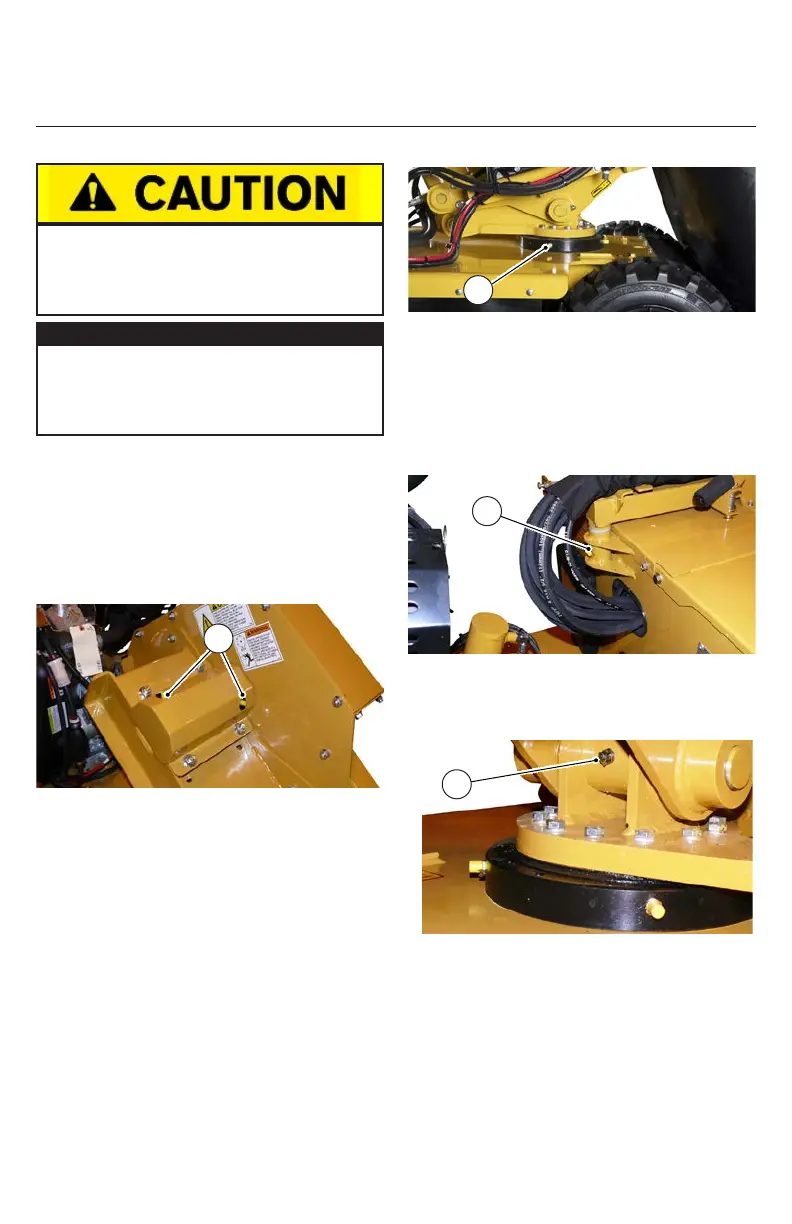

Slewing Ring

Lubricate 3-4 shots of grease into the grease fitting

on the slewing ring (3) (located under the boom asm).

There is a zerk on either side of the slewing ring.

Note: Dried grease can plug holes, if grease does not ooze

out of holes, use very small drill bit to loosen dried grease

/ debris, to ensure grease has been applied properly.

2) Swing-Out Arm Bushing

Lubricate 3-4 shots of grease into the grease fitting on

SOA bushing (4).

3) Pivot Bushing

Lubricate 3-4 shots of grease on the bearing housing (5) at

pivoting end of the boom.

Shoot grease in slowly, and carefully prevent

damage to the bearing seals. Use extra caution

when using a high pressure or high volume

grease gun.

NOTICE

ACCUMULATED GREASE AND OIL ON A MACHINE

IS A FIRE HAZARD. REMOVE SUCH DEBRIS WITH

STEAM CLEAN ING OR HIGH PRESSURE WATER.

SEE THE NOTE BELOW FOR DETAILS.

2

3

4

5

Loading...

Loading...