88

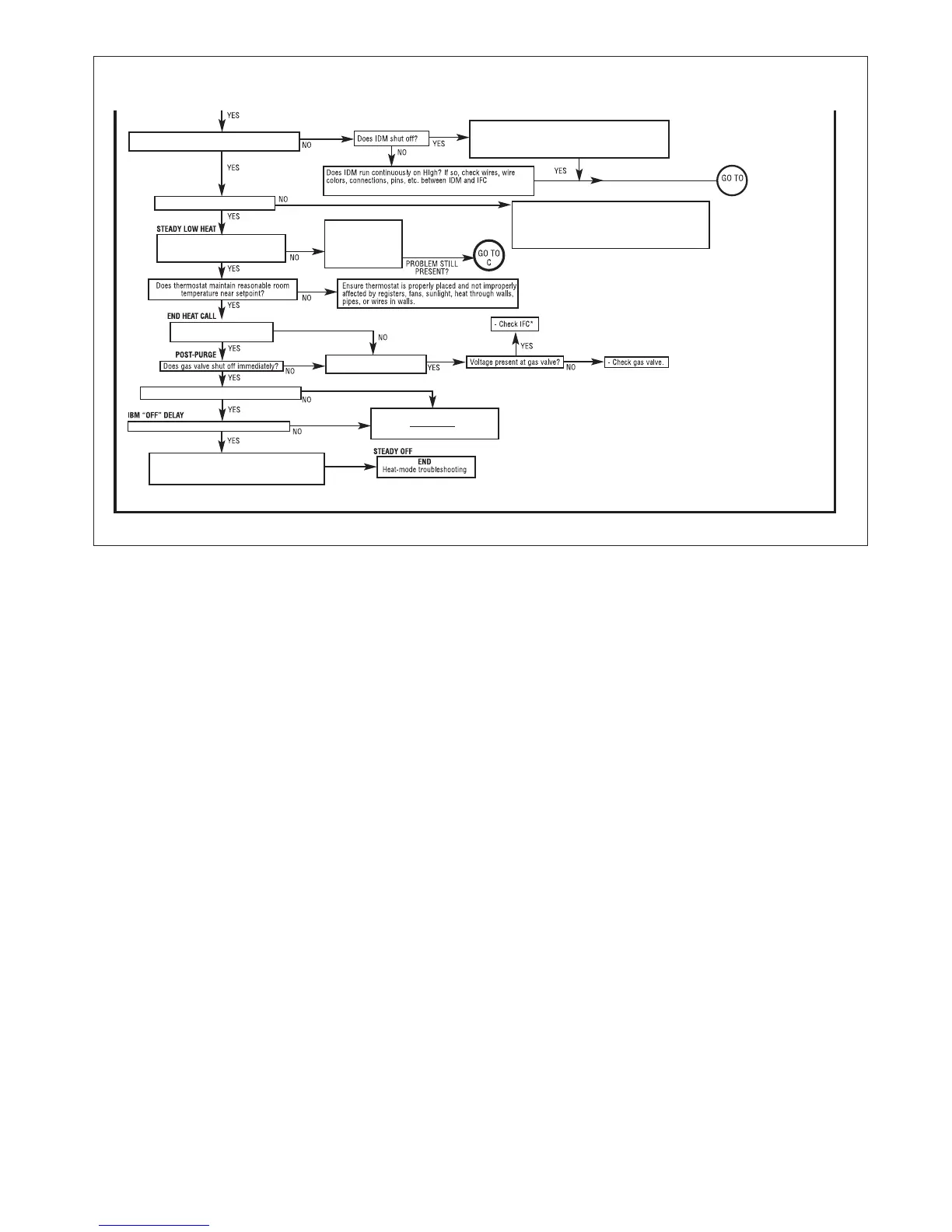

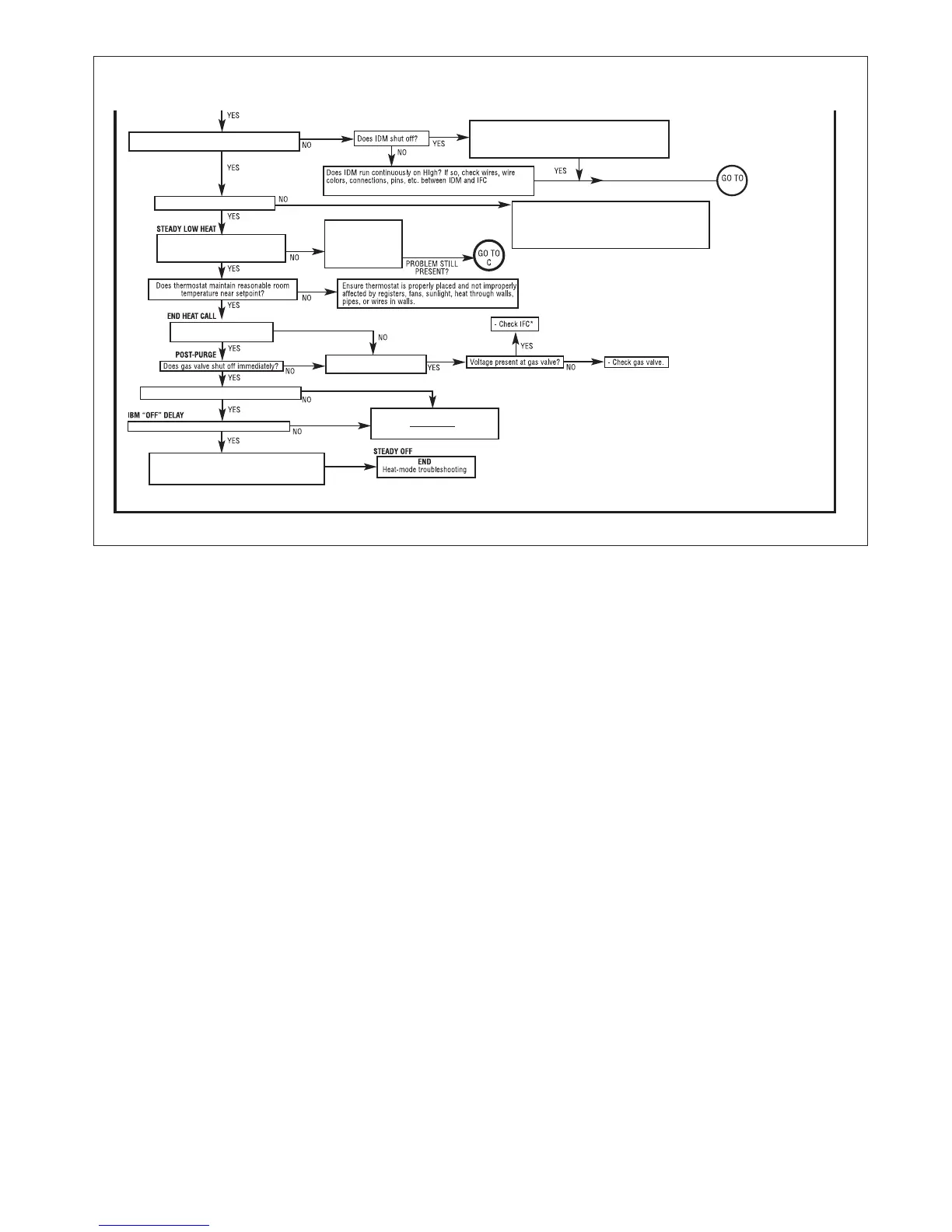

FIGURE 82

TROUBLESHOOTING CHART – CONTINUED

MODULATING INTEGRATED

FURNACE CONTROL (IFC)

TROUBLESHOOTING GUIDE

ECM = Constant CFM Blowers. (Electronically commutated motor)

TSTAT = Thermostat.

IDM = Induced Draft Motor (or Inducer).

IFC = Integrated Furnace Control (or control board).

PS = Pressure Switch(es).

PFC = Power Factor Correction Choke.

SE = Spark Electrode (s).

SSD = Seven Segment Display of Furnace control

COMM. = Communication.

I&O = Instal

lation & Operation Instructions Manual.

1) Set DIP switches SW2-2 to “OFF” and SW2-3 to

“ON” for test mode - high fire.

2) Set FAN switch to “AUTO” on T-stat.

3) Set thermostat to call for heat (set temp.

differential to greater than 10°F).

4) “H” should be displayed at “SSD’s” and should

Be on steady, if flashing check dip switches

(Item “1”).

For Non-Comm. Systems.

“A capital

is displayed at IFC SSD’S”

Dual SSD’S “ON”

92-22744-23-00

Is thermostat heat call present?

For 24 VAC (Non-Comm. T-stat., is 24 VAC on W1 and/or W2 of

IFC. H or h should be displayed at SSD’S.

Is a fault code displayed at IFC?

(After 10 Sec. a fault code will display anyway)

H or h only

For 1st 10 Sec. only

FAULT

Under ”Troubleshooting”

in I & O Manual

Is a modulating

T-stat connected?

Check “V” signal wires &

connections, replace or

repair as necessary

Check t-

stat, replace if

necessary.

(pre-purge) IDM runs for 30 sec. at high speed?

Does IDM Run for 60 Sec. and then off

for five minutes with fault

45, 48 or 57 displayed?

- See FAULT CODES under “Troubleshooting” in

I&O Manual.

J16-4

J16-5 on IFC.

If IFC goes into lockout (”r” will be displayed at SSD’s), shut off

main power to unit, wait 30 seconds then reset power or removed heat

call and re-establish.

- Check all connections between I.F.C. & E.C.M. Motor.

- Check 24v to E.C.M. control (4pin connector, pin 1-4)

- Check Dip switch setting.

- Check P.F.C. choke.

- Check all wiring and connections to P.F.C choke.

- Check fault code display, see

“fault codes” in I & O.

- Check line voltage to motor (115VAC).

Does ECM blower start on high heat

speed 15-20 seconds after burners light?

Note: IFC SSD’s will display “22, 33 or 23”.

?

If good flame is not sensed a fault code

“11” or “13” will be displayed at SSD’s

“12” is low flame sense, furnace should

still operate well.

Fault code

“45”, “46” or

“57” displayed

at SSD’s.

- Check test mode dip switches.

- Make sure test mode has not

expired (1 hour limit).

- Fault codes at IFC SSD - see FAULT CODES under troubleshooting

in I&O manual.

- 24V Between IFC pins J16, Pin 4 & J16, Pin 5 of I.F.C.

- Make sure heat call present at T-stat.

- T-stat wires and connections

Remove heat call by setting T-stat set point below

room temperature. remove power to furnace and open

blower door. Set dip switch SW2-2 to “ON” and SW2-3

to “OFF”. Replace furnace door, reset po

wer to

furnace. Initiate new heat call. Allow heat call to

proceed through blower on delay. The burners drop

from high fire to low (40%) rate and I.B.M. energizes at

low heat CFM.

Check to make sure test mode dip switches are properly set.

- Check all connections between IFC and ECM motor.

- Check 24V to ECM Motor. (low voltage connector, pins 1 & 4)

- Check P.F.C. Choke.

- Check all wiring and connections to P.F.C. choke.

- Check fault code display and see “fault codes” In I & O.

Does I. B. M. energize at low speed?

After Blower on delay, Does IDM switch to low speed

and remain a

t low speed after switching?

Does furnace continue to operate at low

fire until T-stat satisfied or heat call

removed?

Ensure T-stat not

switching to high fire or

test mode dips witches

not timing out (1 hour

limit)

Fault code displayed?

See FAULT CODES under

troubelshooting in the I & O Manual

Does IDM Shut off after Twenty Second post purge?

Does I. B. M. shut off after 90 seconds? (plus slew)

Double check - is heat call

completely off at IFC?

** System will attempt to light 4 times. Voltage Is present at gas valve for

only 7 seconds during each ignition trial. System will enter a 1 hour

lockout after 4 attempts.

For Comm. System

Lower case “h”

Capital “H”

2 Stg. or 1 Stg. Non Comm. T-stat

-Check line voltage at I.D.M.

-Check Wires And connections between I.D.M. and I.F.C.

-Ensure line voltage between J2, Pin 1 & J2, Pin 4 of I.F.C. (High IN Output).

-Check I.D.M. Capacitor.

Spark Electrodes (SE) Energize?

See I&O.

Does gas valve remain

energized?

PROBLEM

PERSISTS

- ensure no restrictions, such as dirty filter, blower wheel,

dampers or closed registers, Etc. exist.

- ensure good wire and connections between I.F.C. and all limits.

makes sure limits are not open when circulating air temperature is within a

specific range.

- Ensure rollouts or overtemperature limits do not need to be

reset. make sure no flame rollout in burner compartment due to blocked flue

or heat exchanger or combustion restriction.

- ensure furnace is not overfired (temp rise is above stated

range). Check gas valve, proper orifice size, gas presure

-Grounding on I.F.C. in place and continuity between screw and field

-installed ground.

-Flame sense rod clean (clean if nessessary).

-Wire continunity between flame sense rod and J1, Pin1 on I.F.C.

-Flame carries across all burners, and all burners stay lit.

Remove heat call by setting

T-stat below room temp.

Remove power to furnace, open blower compartment

and restore dip switches to original settings. Replace

blower door. Restore power to unit.

- Check wire and all connections between I.F.C.J2 and I.D.M

- Check for 115 VAC on P2.

- Check I.D.M. capacitor.

- Check I.D.M. low speed. Replace if neccessary.

C

Loading...

Loading...