66

For non-communicating systems or

communicating systems with a non-

communicating condenser (see section

titled SPECIAL CONFIGURATION –

COMMUNICATING THERMOSTAT

AND FURNACE WITH A NON-COM-

MUNICATING CONDENSER of this

document), the target cooling airflow

will be determined by the adjustments

of SW1-1 and SW1-2. Furnaces with

½ HP motors will have a maximum tar-

get airflow setting of 1200 CFM.

Furnace with 1

HP motors will have a

maximum target airflow setting of 2000

CFM. The airflow achieved may be

less than the target if the static pres-

sure across the furnace is over 0.6” wc.

Consult the cooling equipment instruc-

tions and documents for target airflow

and adjust accordingly.

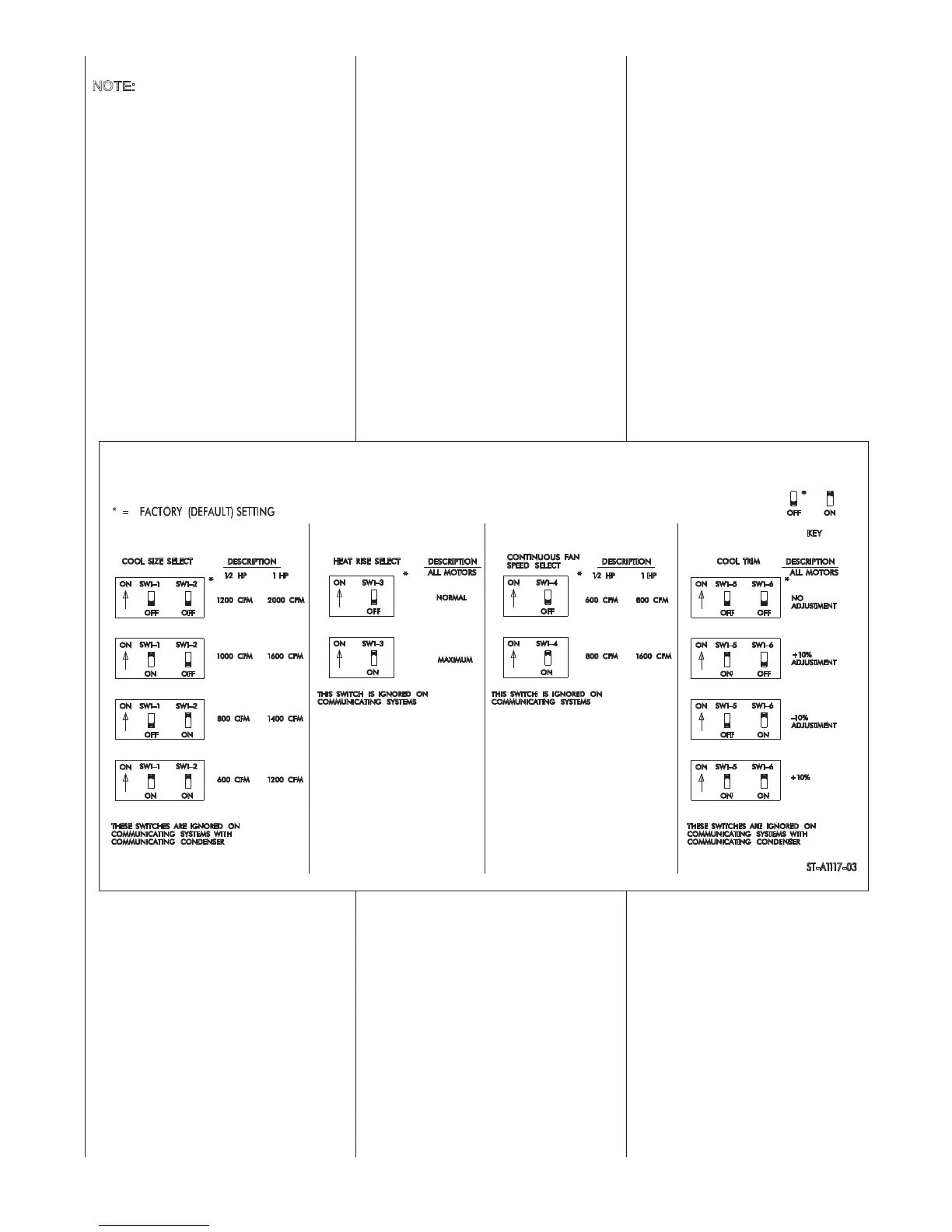

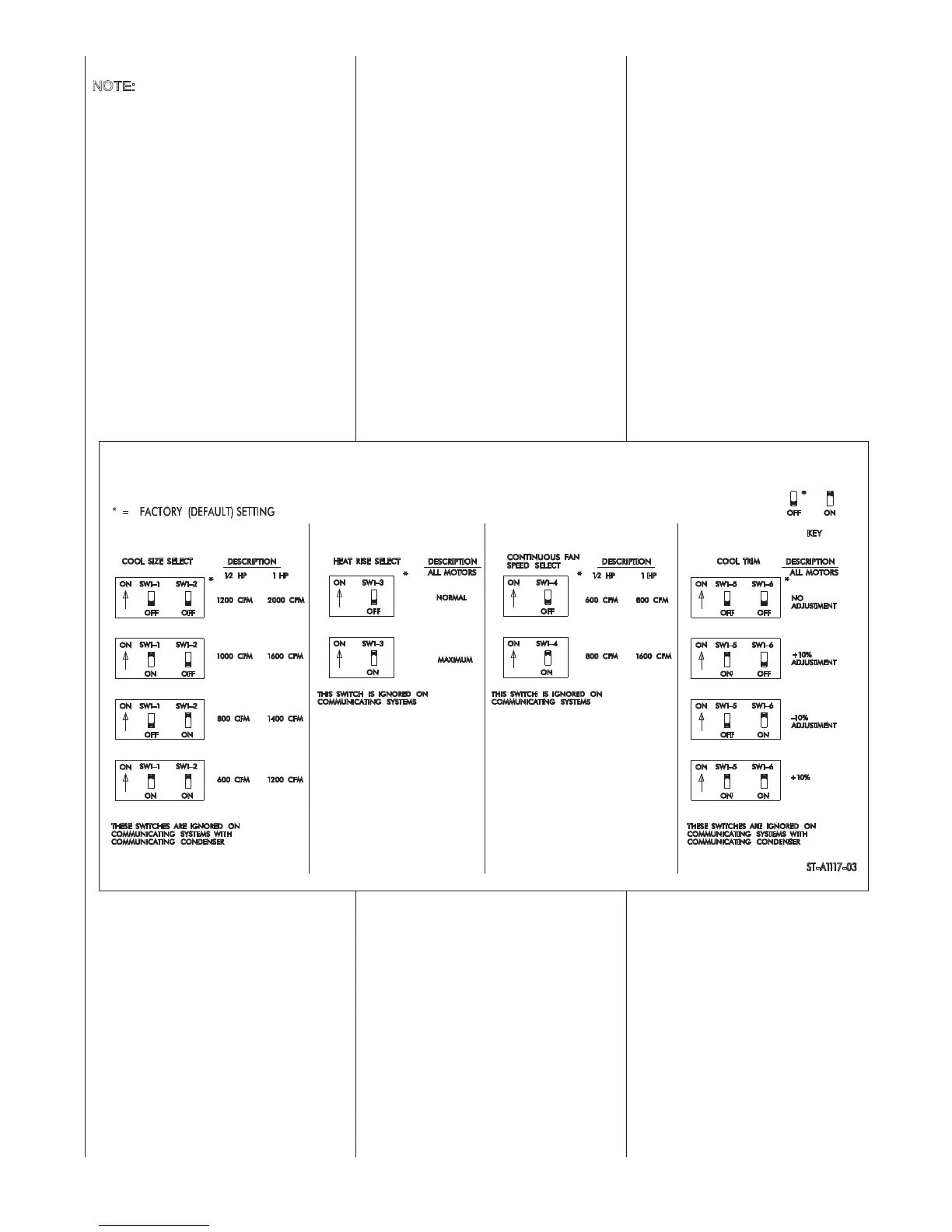

DIPSWITCHES

NOTE:

The integrated furnace control

does not recognize switch setting

changes while energized.

SW1

SW1-1 AND SW1-2 – COOLING AIR-

FLOW SELECT – These dipswitches

are used to select the appropriate cool-

ing airflow based on the amount

required. The switch settings do not

affect cooling airflow when installed with

a fully communicating condenser. In

that case, the condenser supplies the

information for cooling ai

rflow which is

preset at the factory and not adjustable.

Cooling airflow for non-communicat-

ing systems can be adjusted

approximately +/- 10% by using the

cool trim adjustment dipswitches;

SW1-5 and SW1-6. See Figure 66.

Cooling airflow for non-communicat-

ing systems is also affected by the

settings of dipswitch position SW2-6.

This switch will determine the appro-

priate amount of airflow to be used

for t

he low stage (1

st

stage) of cool-

ing. See the tables in Figure 67.

More information can be found in

the section titled SW2 (SW2-6).

Consult the tables in Figures 66, 67

and 68 for target airflow settings and

adjustments based on the positions

of the dipswitches SW1-1, SW1-2,

SW1-5, SW1-6 and SW2-6.

FIGURE 66

DIPSWITCH BANK SW1

Loading...

Loading...