S&C Instruction Sheet 716-504 11

Installation

Before Starting

CAUTION

Do not remove the containers from the

interrupters or the plastic bubble wrap from

the insulating support columns until the

installation is complete.

NOTICE

Bolted and Pinned Connections: A typical

bolted connection requires a flat washer

underneath the cap screw and one under the

nut. When self-locking hex nuts are specified,

it is essential that the threads of the associated

cap screw be lubricated with a general-

purpose grease to facilitate tightening. All pins

and cotter pins used in field assembly should

also be lubricated to facilitate insertion.

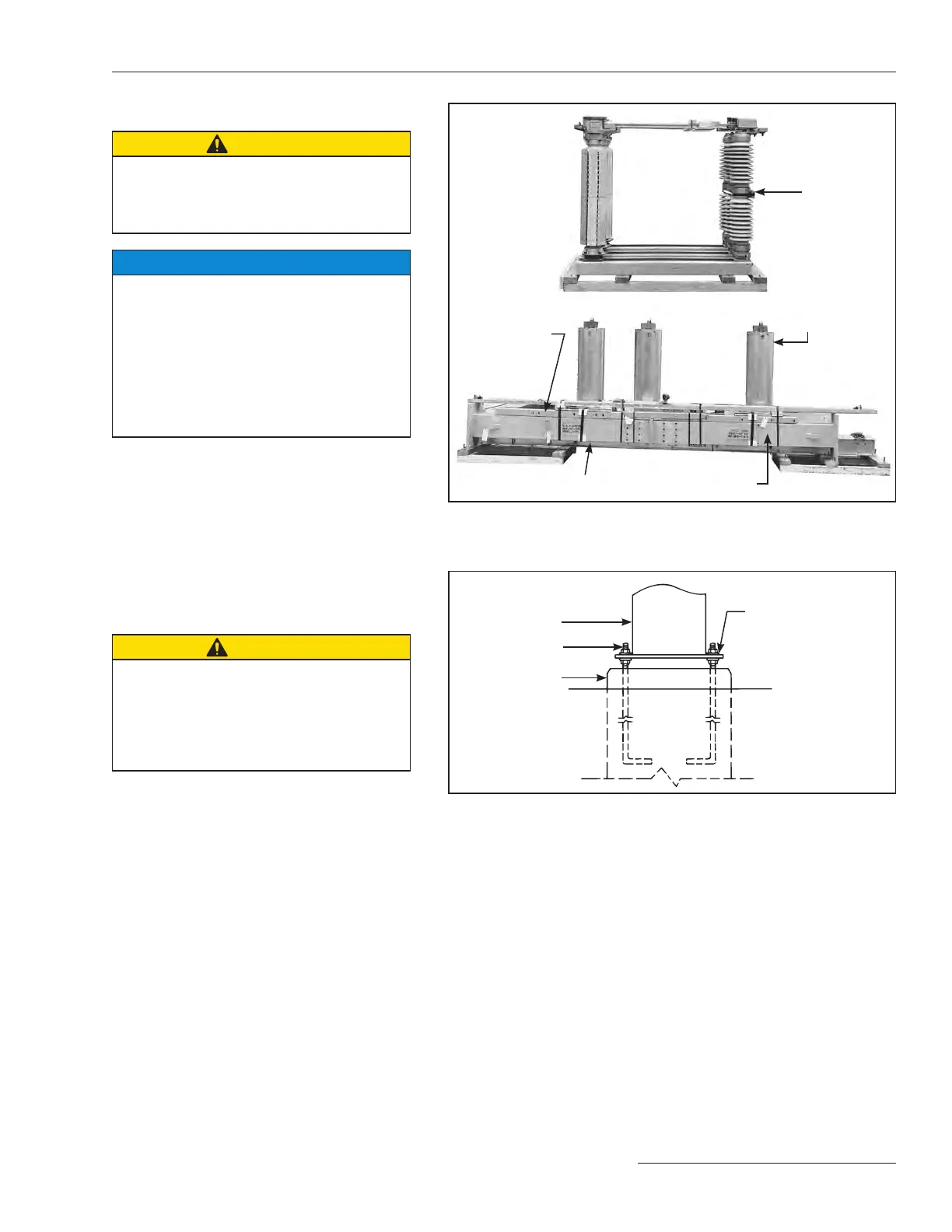

Step 1

Use a steel strapping cutter to cut the steel

straps that bind the mounting pedestals and

support arms to the high-speed base. Also cut

the straps that bind the container of operating

mechanism components and hardware and the

straps that bind the pole-units. Also remove the

wood bracing between the pole-unit terminal

pads. See Figure2.

CAUTION

The foundations and anchor bolts for S&C

Mounting Pedestals must be designed to

meet the loading limits specified in S&C

Data Bulletin 716-61. Failure to meet these

loading limits can result in personal injury

or equipment damage.

Installing the Mounting Pedestals

and High-Speed Base

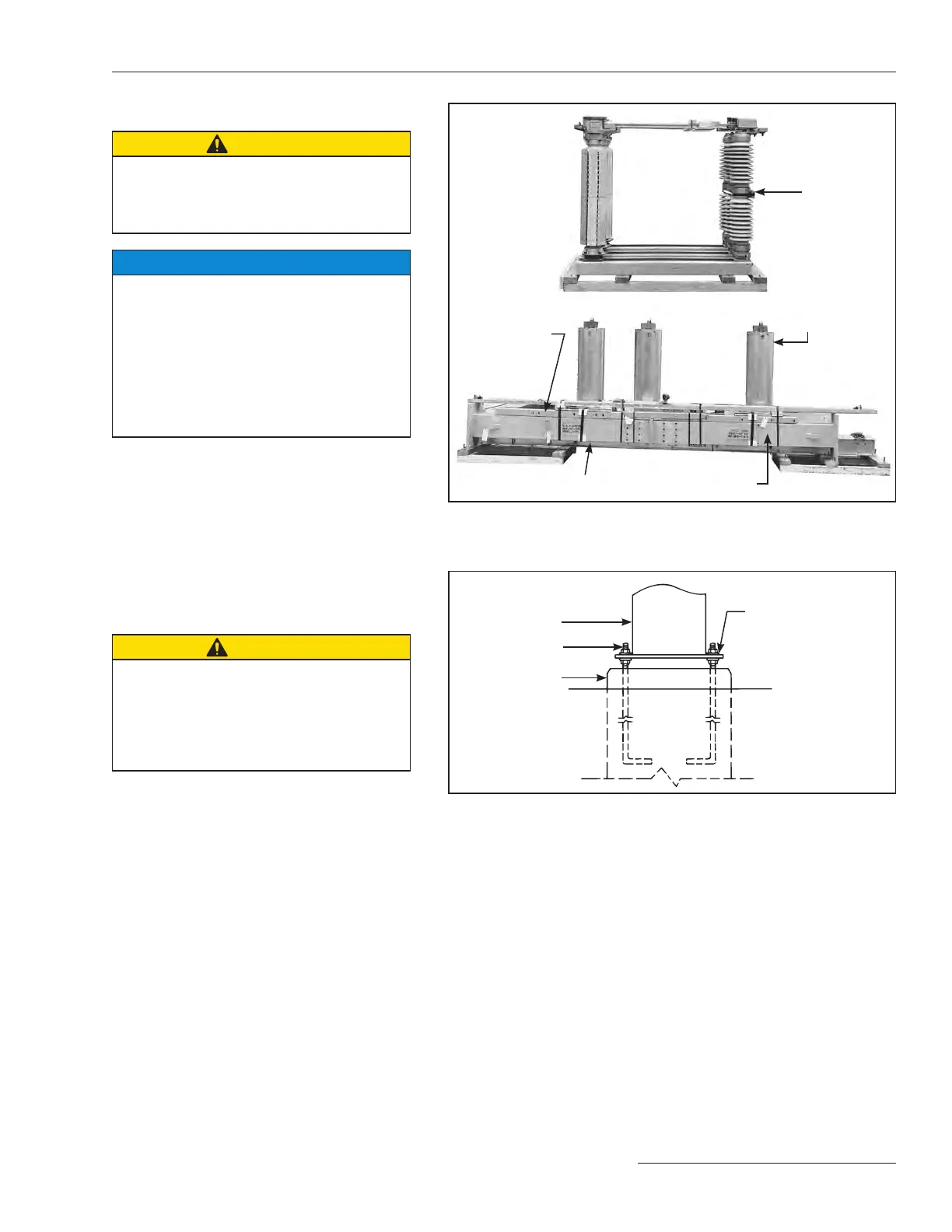

Step 2

Install each pedestal as follows:

(a) Install the lower set of anchor bolt nuts

and at washers onto the pre-installed

anchor bolts. Level all anchor bolts to the

same height leaving space below and

above the bolt for leveling. See Figure3.

Figure 2. Typical shipment of Model 2020 Series 2000 Circuit-Switcher.

Operator is shipped on a separate skid.

Pole-unit

Interrupter

(inside container)

High-Speed base

Support arms

Mounting pedestal

Figure 3. Pedestal anchor-bolt mounting detail.

Two nuts and two

flat washers provide

leveling means

Pedestal

Anchor bolts

Concrete pad

Loading...

Loading...