S&C Instruction Sheet 716-504 33

Installation

Step 36

When the circuit-switcher is ready to be placed

in service, the motor and closing circuit fuses

can—at the user’s option—be replaced with the

slugs furnished. This practice is recommended

for increased reliability because low-voltage

fuses can be damaged by the repeated inrush

current experienced during normal opening and

closing operations and can "sneak out," leaving

the circuit-switcher inoperable.

NOTICE

Before replacing these fuses with slugs,

make certain that the control-source battery

is adequately protected to prevent discharge

using fuses or circuit breakers located at the

battery bus.

Step 37

Please complete and mail the circuit-switcher

registration card. The information requested on

this card is vital to ensure prompt notication in

the event eld modications are needed.

Adjusting Auxiliary-Switch Contacts

Two individually adjustable auxiliary-switch

contacts are furnished in the operator. These

contacts follow the position of the disconnect-

blade power train and operator when the power

train is coupled and the position of the operator

when the power train is decoupled.

Step 38

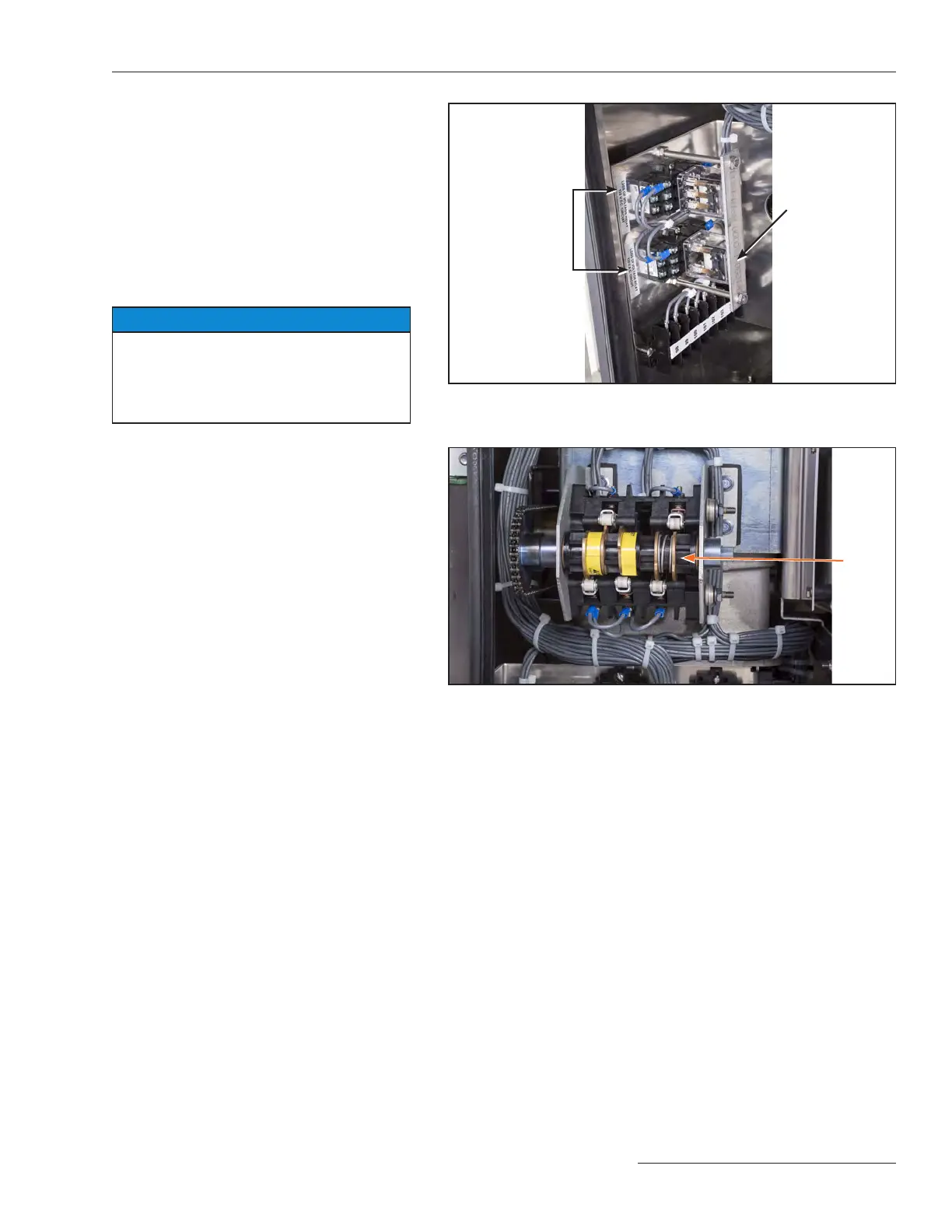

Each auxiliary-switch contact is operated by

a cam-actuated roller. A contact is closed if its

roller is disengaged from a cam and, conversely,

a contact is open if its roller is engaged with a

cam. The cams are individually adjustable in

4.5-degree increments.

To adjust the contacts:

(a) Push the cam toward its adjacent spring

until the cam is separated from the teeth

of the inner gear. See Figure 40.

(b) Rotate the cam to advance or delay

engagement with its roller.

(c) Release the cam, making sure the teeth

are engaged with the inner gear.

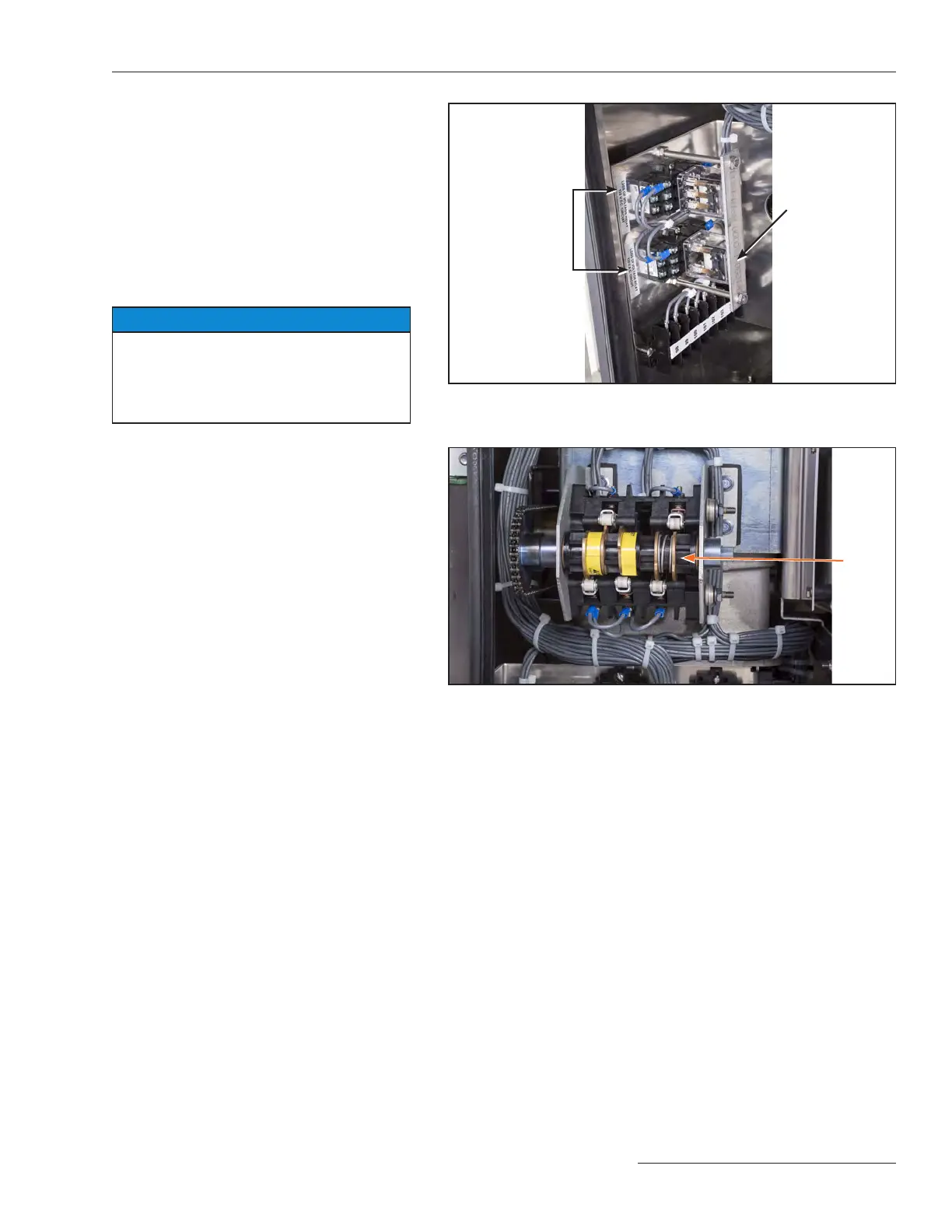

Figure 39. Check that all optional “ice cube” style relays are fully seated

and that the retaining plate is in place.

Figure 40. Adjust the cams on the auxiliary switch.

Cam

Optional relays

Relay holder

Loading...

Loading...