S&C Instruction Sheet 716-504 13

Installation

CAUTION

The operator directly drives the interrupters

open and closed through a simple high-

speed power train leading from the top of

the operator, through a horizontal interphase

linkage enclosed in a steel-sheathed high-

speed base, to reciprocating-action insulated

operating rods that pass through the center of

the insulating support columns. Permanently

lubricated bearings are used throughout the

power train. The high-speed base has been

fully pre-assembled and adjusted at the

factory. DO NOT disassemble the high-

speed base or high-speed power train.

Damage to the high-speed base and personal

injury may result.

Step 4

Loosely bolt the high-speed base to the

support arms using the ½–12×2-inch hex-head

galvanized steel cap screws, at washers, and

self-locking hex nuts furnished.

Lubricate the bolts to facilitate tightening.

Use a level to verify the high-speed base is hori-

zontal, both lengthwise and sideways. Adjust

the lower set of anchor bolt nuts at the pedestals

to achieve level. See Figure3 on page11.

If necessary, loosen the ⅝–11×1¼-inch hex

head galvanized steel cap screws that attach

the support arms to the mounting pedestals,

reposition the support arms, and retighten the

cap screws.

Step 5

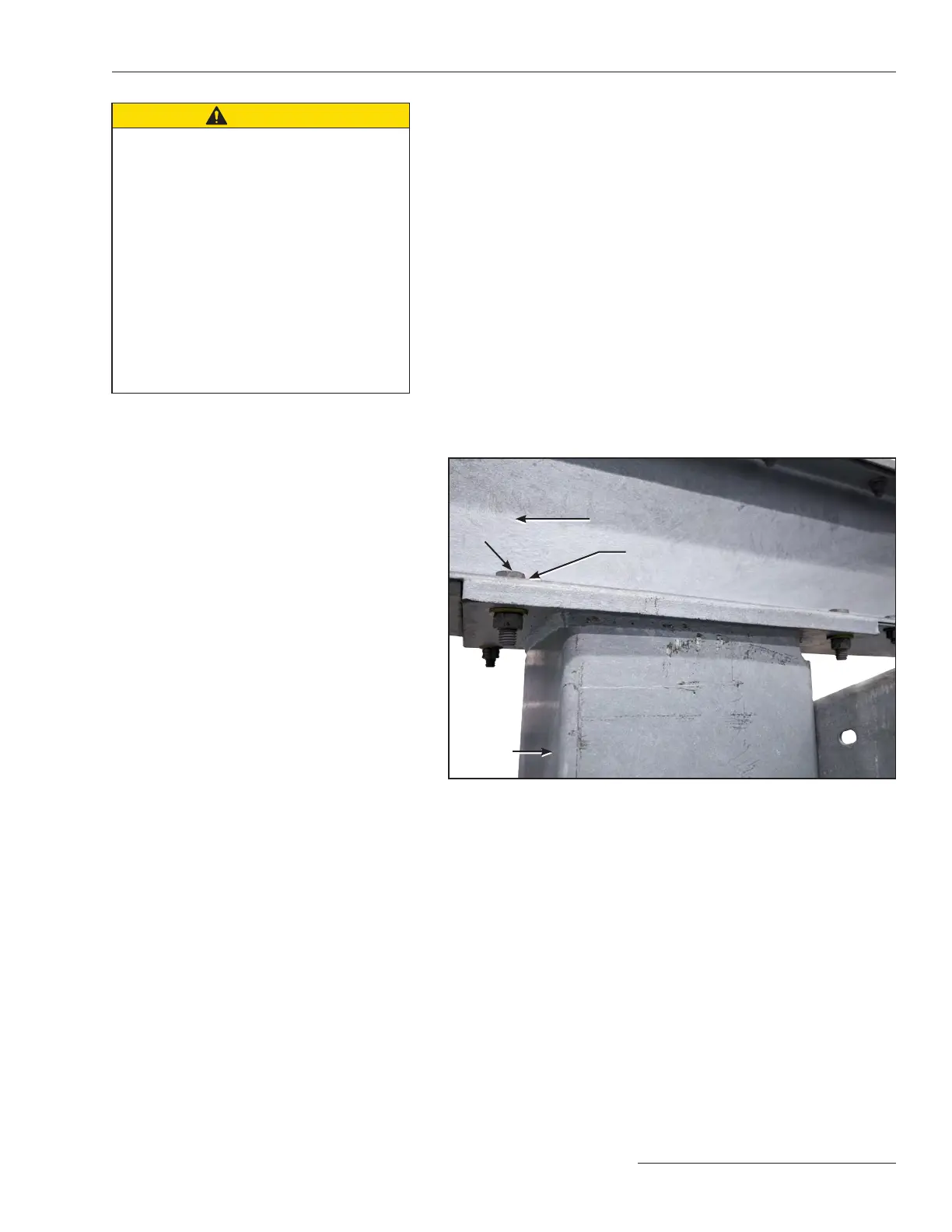

Examine the bottom of the high-speed base

where it comes in contact with the support

arms. If necessary, install shims between

the high-speed base and the support arms to

compensate for any gaps greater than ⅛-inch

(3.175 mm) between the mating surfaces. See

Figure6.

Tighten the bolts on the high-speed base to

75 ft./lbs.

On 69-kV circuit-switchers with 48-inch

phase spacing: support arm gussets are not

used; the high-speed base is attached atop the

mounting pedestal using ⅝–11×2¼-inch hex-

head galvanized steel cap screws, flat washers,

and self-locking hex nuts. Shim between the

high-speed base and the pedestal if necessary.

Step 6

Refer to the catalog drawing and attach the

support brace to the support arms, using the

spacers, ½–12×2-inch hex-head galvanized

steel cap screws, at washers, and self-locking

hex nuts furnished. Securely tighten the

associated cap screws.

Figure 6. Shim under the high-speed base for gaps of more than ⅛-inch.

(69 kV shown, 115 and 138 kV similar.)

Pedestal

High-speed base

Shims

(if required)

Bolts

Loading...

Loading...