S&C Instruction Sheet 716-504 15

Installation

Step 10

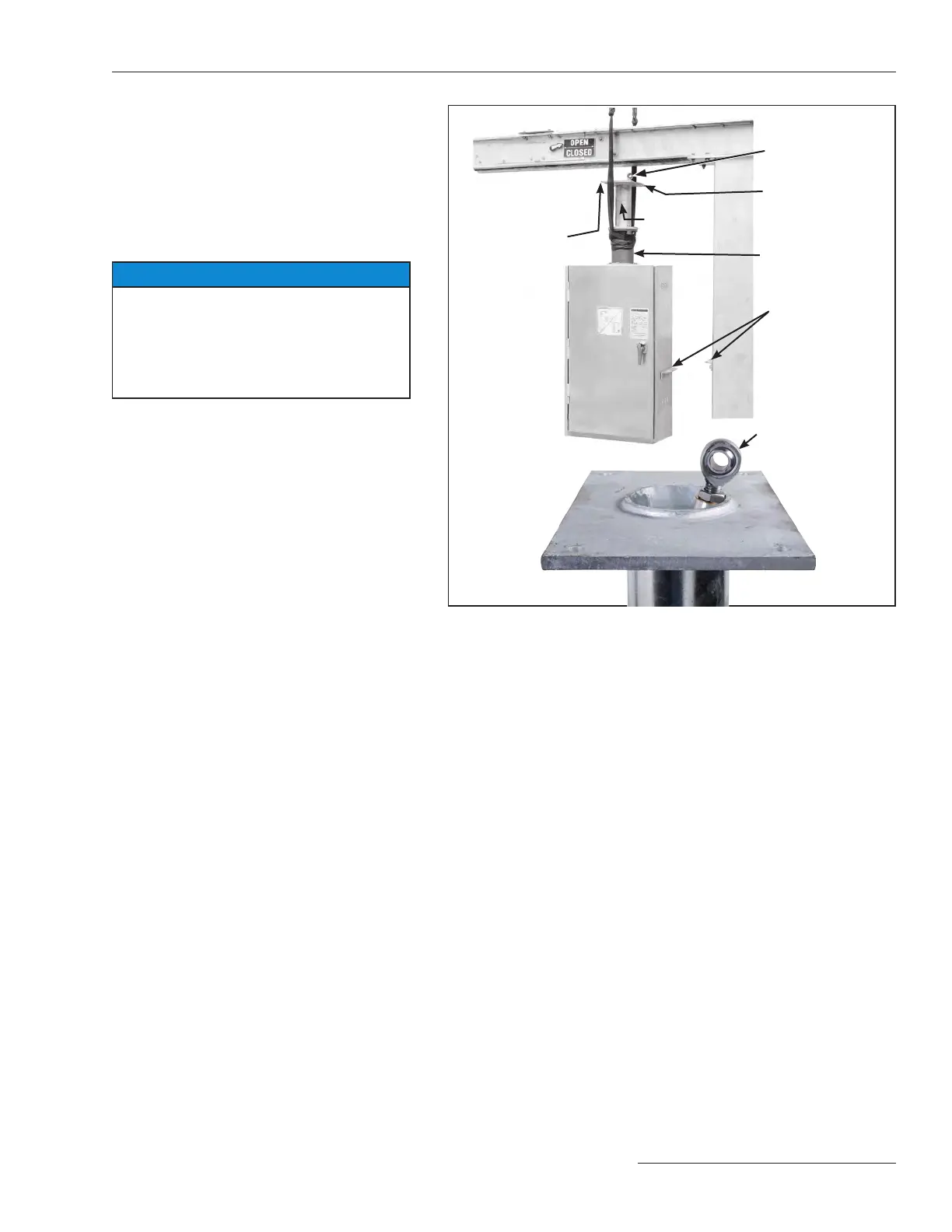

Reposition the lifting sling around the front of

the stored-energy housing and wrap another

lifting sling around the back of the stored-

energy housing, as shown in Figure 10. Face the

operator door the same direction as the switch

position indicator on the high-speed base. Hoist

the operator into place.

NOTICE

DO NOT damage the uni-ball coupling on

the operator connecting link during hoisting

and attachment of the operator. The uni-

ball coupling cannot be replaced in the

field. Damage will necessitate returning the

operator for replacement.

Attach the operator support tube mounting

plate to the underside of the high-speed base

using four ½–13×1¾-inch hex-head galvanized

steel cap screws, flat washers, and self-locking

hex nuts. Lubricate the bolts to facilitate tight-

ening. Tighten all four screws securely.

Step 11

Attach the operator support angle to the

appropriate mounting pedestal using two

⅝–11×14-inch hex-head galvanized steel cap

screws, four at washers, and two self-locking

hex nuts. Refer to the catalog drawing for exact

placement. See Figure 10.

Attach the operator support plate to the

angle on the operator, and the angle on the

mounting pedestal using four ½–13×1½-inch

hex-head galvanized steel cap screws, flat wash-

ers, and self-locking hex nuts furnished. Lubri-

cate the bolts to facilitate tightening. Securely

tighten the screws. On circuit-switchers with

two mounting pedestals, insert the hole plugs

furnished into all unused holes in the pedestals.

Figure 10. Hoist operator into position below the high-speed base using

a lifting crane.

Uni-ball coupling

Operator

support

tube

Stored-energy

housing

Uni-ball coupling

Operator support

tube mounting

plate

Holes for

½ –132¾-inch

hex-

head galvanized

steel cap screws,

flat washers, and

self-locking nuts

Operator

support

angles

Loading...

Loading...