21F-PD250 / 21F-PT220 / 21F-PA18 / 21F-PA18(B)

3 – 15

2. PURITY ADJUSTMENT

No.

Adjustment point

Adjustment procedure/conditions Waveform and others

1. Receive the GREEN-ONLY signal. Adjust the

beam current to ~700 µA .

2. Degauss the CRT enough with the degausing coil.

Note: Follow the Job Instruction Sheet to adjust

the magnetic field.

(Reference: page 3-5)

3. Maintain the purity magnet at the zero magnetic

field and keep the static convergence roughly

adjusted.

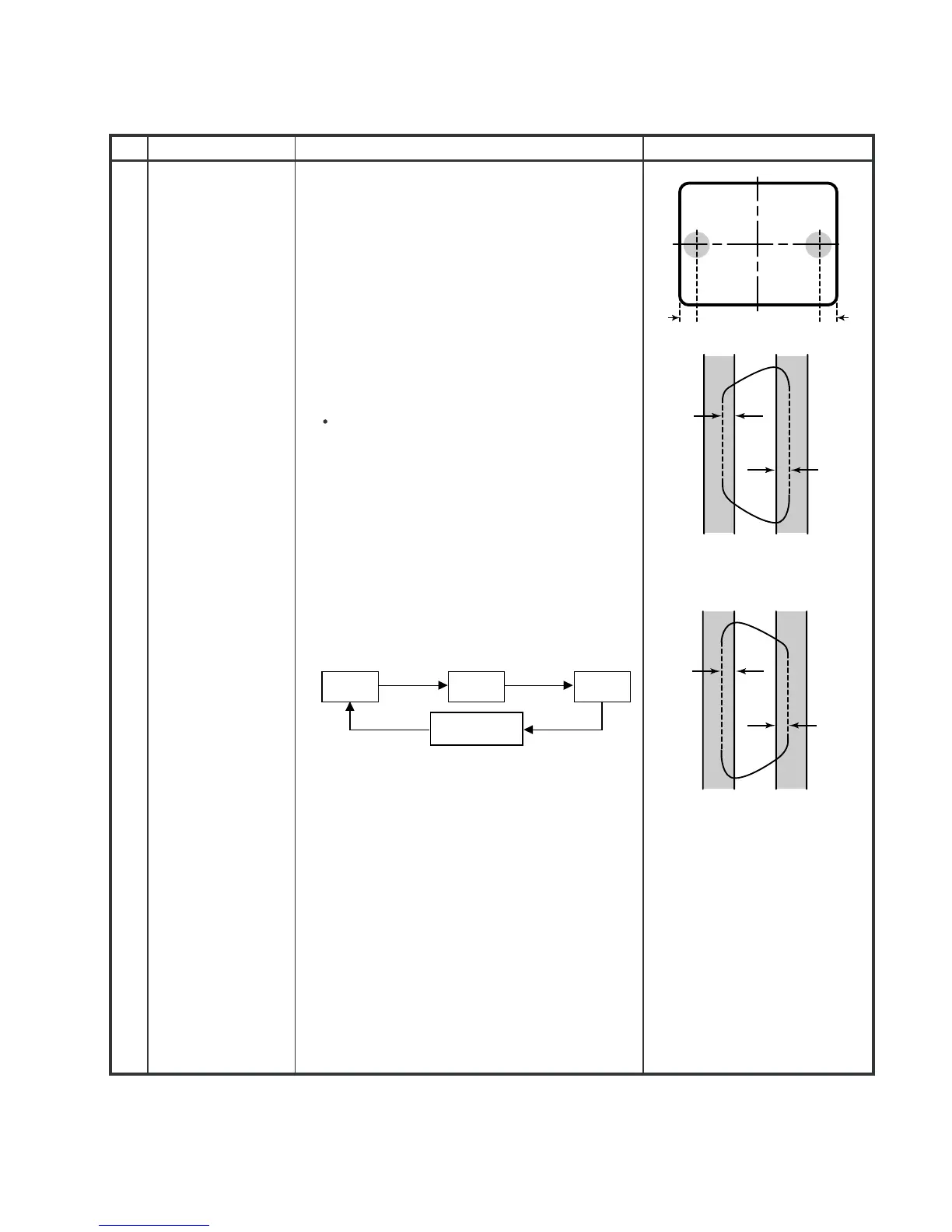

4. Observe the points a, b,as shown in Fig. 1-1

through the microscope. Adjust the landings to A

rank requirement.

5. Orient the raster rotation to 0 eastward.

6. Tighten up the deflection coil screws.

Tightening torque: 108 ± 20 N (11kgf ± 2 kgf)

7. Make sure the CRT corners landing meet the A

rank requirements. If not, stick the magnet sheet

to correct it.

Note: This adjustment must be done after

warming up the unit for 30 minutes or

longer with a beam current over 700

µ

A.

Note:

* For the following colours press R/C RGB(Hex 7E)

key to change.

PURITY ADJ.

(No need if used

ITC CRT)

1

a

b

A

B

A

30mm 30mm

B

A=B

A=B

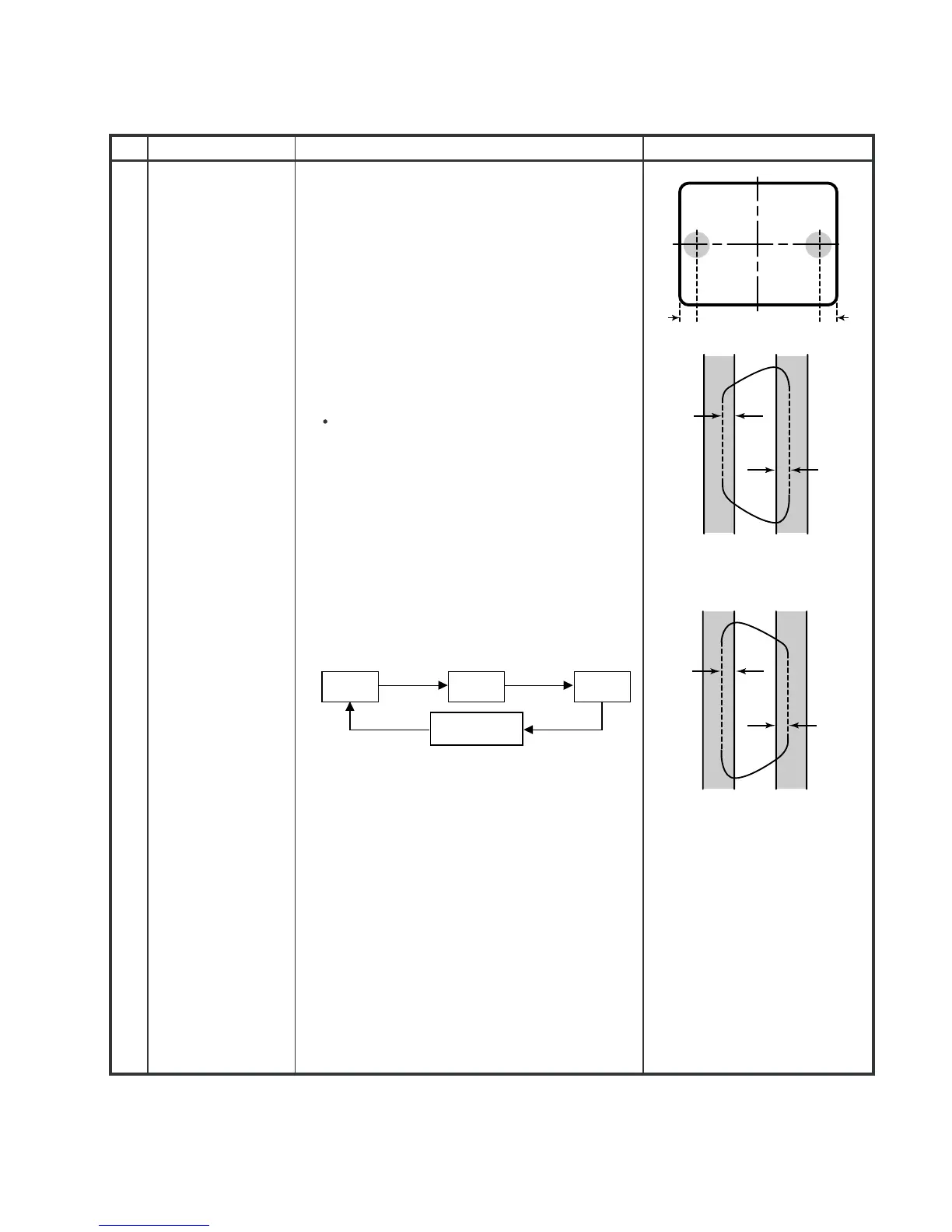

Rank "A"

(on the right of the CRT)

Rank "A"

(on the left of the CRT)

Fig. 1-1

Fig. 1-2

Fig. 1-3

* Press R/C RGB key for 1 sec-

ond in NORMAL MODE, the

colour will change to RGB

mono colour mode.

Signal-colour

screen cleared

GREEN

ONLY

BLUE

ONLY

RED

ONLY

Set to service mode by remote con-

troller then press factory process R/C

RGB key to change to RGB mono col-

our mode.

Loading...

Loading...