2

2687

12 2020

-

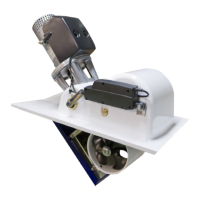

SE80 & SE100 & SE120 & SE130 & SE150

DECLARATION OF CONFORMITY

Sleipner Motor AS

P.O. Box 519, Arne Svendsensgt. 6-8

N-1612 Fredrikstad, Norway

Declare that this product with accompanying standard control systems complies with

the essential health and safety requirements according to:

DIRECTIVE 2013/53/EU

DIRECTIVE 2014/30/EU

DIRECTIVE 2014/35/EU

MC_0020

Contents

EN

Bow Installation Instructions

Bow Installation Considerations and Precautions ..................... 3

Thruster Measurements .......................................................... 4

Thruster Specications .............................................................. 5

Technical Specications .......................................................... 5

Positioning of the tunnel / thruster ............................................. 6

Tunnel Length ............................................................................ 7

Tunnel installation in sailboats ................................................... 8

Water Deection ........................................................................ 9

Tunnel ends ............................................................................. 10

Tunnel installation ............................................................. 11 - 12

Stern tunnel installation ........................................................... 13

Thruster Installation Instructions

Thruster Installation Considerations and Precautions ............. 14

Gear Leg & Motor Bracket Installation..................................... 15

Propeller Installation ................................................................ 16

Motor Installation ..................................................................... 17

Thruster Electrical Installation ................................................. 18

Electrical Specications .......................................................... 19

Control Panel Cable Installation ............................................. 20

Visual Wiring Diagram ............................................................ 21

Technical Wiring Diagram ....................................................... 22

Control Panel Installation ........................................................ 23

Pre-delivery Checklist .......................................................... 24

Spare Parts ............................................................................ 25

Warranty statement .............................................................. 25

MC_0031

Bow Installation Considerations and Precautions

EN

• The thruster must NOT be installed in compartments that require ignition proof electric equipment. If necessary, make a separate compartment.

(NB: Ignition Protected systems are tested to be installed in areas with possible explosive gases in accordance with ISO 8846)

• The electromotor will generate some carbon dust so any storage compartments must be separated from the thruster to prevent nearby items

becoming dusty/ dirty. (NB: IP version motors generate dust but are enclosed.)

• When installing the thruster electromotor in small compartments, ensure the compartment is well ventilated to allow for cooling of the electromotor.

• If the height of the room you are installing the thruster is limited, the thruster can be installed horizontally or at any angle in-between.

- If the electromotor is positioned more than 30º off vertical, it must be supported separately.

- Beware of keeping installation within advised measurements. No part of the propeller or gear house must be outside the tunnel.

• Do not install the thruster in a position where you need to cut a stiff ener/ stringer/ support that may jeopardise the hull integrity without checking with

the boat builder this can be done safely.

• The electromotor, components and cables must be mounted so they remain dry at all times.

• We advise painting the gear house and propellers with antifouling. (NB: Do not paint the anodes, sealings, rubber fi ttings or propeller shafts)

• Do not nish the inside of the tunnel with a layer of gelcoat/ topcoat or similar. There is only room for a thin coat of primer and two layers of anti-fouling

between the tunnel and the props.

• Don’t install the electromotor close to easily ammable objects or equipment as it will reach over 100°C before the temperature switch is activated.

• Do not store items close to the thruster motor. Any loose items near the thruster motor cis a potential re hazard and can cause undesired short-

circuiting.

Products

SE150/215T-24V - SE150 Tunnel thruster, 24V

SE150/215T-24 - SE150 Tunnel thruster, 24V

SE130/250T-24V - SE130 Tunnel thruster, 24V

SE130/250T-12V - SE130 Tunnel thruster, 12V

SE120/215T-24 - SE120 Tunnel thruster, 24V

SE120/215T-24V - SE120 Tunnel thruster, 24V

SE100/185T-24V - SE100 Tunnel thruster, 24V

SE100/185T-12V - SE100 Tunnel thruster, 12V

SE80/185T-24V - SE80 Tunnel thruster, 24V

SE80/185T-12V - SE80 Tunnel thruster, 12V

Loading...

Loading...