8

2687

12 2020

-

SE80 & SE100 & SE120 & SE130 & SE150

MG_0004

Min

Pos. B

Pos. A

1

1

2

3

4 65

MG_0048

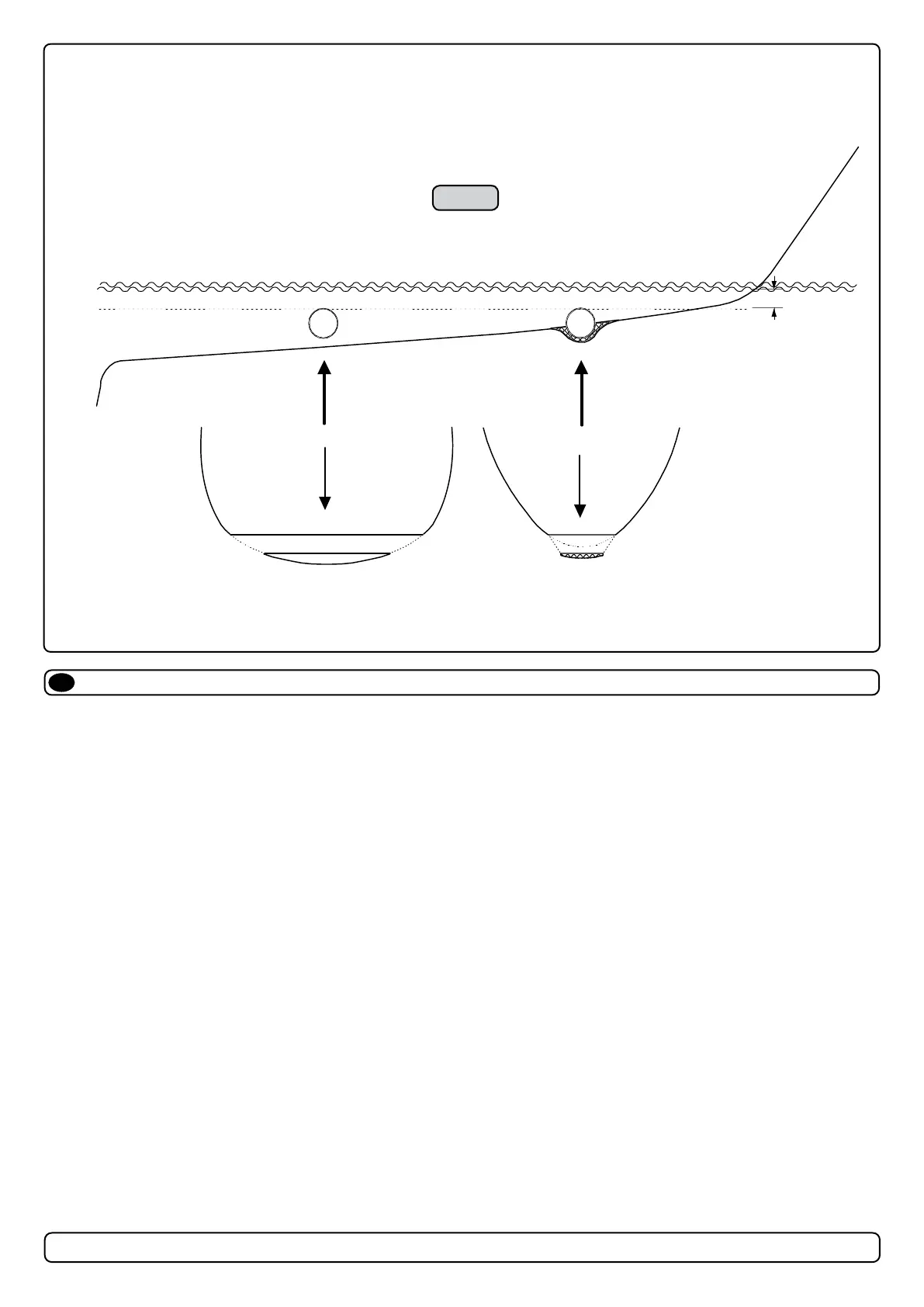

Increase tunnel length to protect

the propeller from water forces

when high-speed cruising.

Water

Forces

Increase tunnel length to prevent

a circular water vacuum cavity

between the propeller and the

hull of the boat.

STANDARD USE FLAT BOTTOM HULL HIGH-SPEED OPERATION

Do not allow the variable length of the tunnel walls to vary in length

excessively.

EG. the top tunnel wall is x 4 longer than the bottom wall.

Cavitation

Water flow must have

space to "straighten"

itself for best

performance.

The gear leg/ propeller(s) must

never extend out of the tunnel

Tunnel installation in sailboats

EN

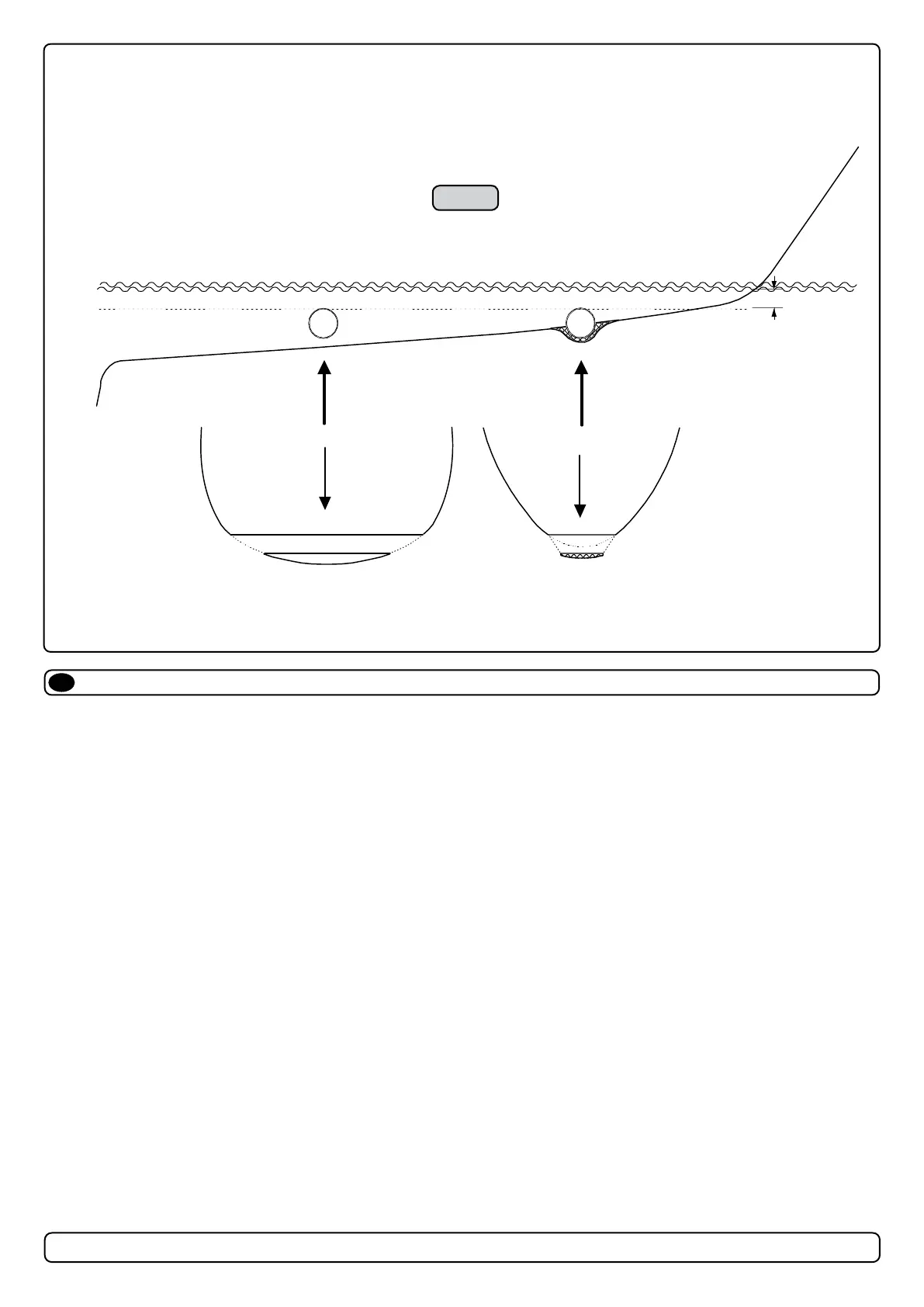

Some sailboats have a at bottom and shallow draft in the bow section. This can make installing the thruster as far forward from the boats main pivot

point diffi cult. (Fig. 1).

However, it is possible to install a tunnel thruster in most sailboats, even when the hull does not directly support the tting of a tunnel.

Instead t the tunnel halfway into the underneath section of the existing hull. Strengthen it with a de ector/ spoiler directing the water ow around the

tunnel. This will allow installation of the thruster in the proper position on the boat, maintaining the reliability and space advantages of the tunnel thruster.

This installation is being used by some of the world’s largest sailboat builders and has proven to give little to no speed loss during normal cruising. This

can also be an installation method for at bottomed barges to avoid extremely long tunnels and large oval tunnel openings in the hull.

MC_0003

Loading...

Loading...