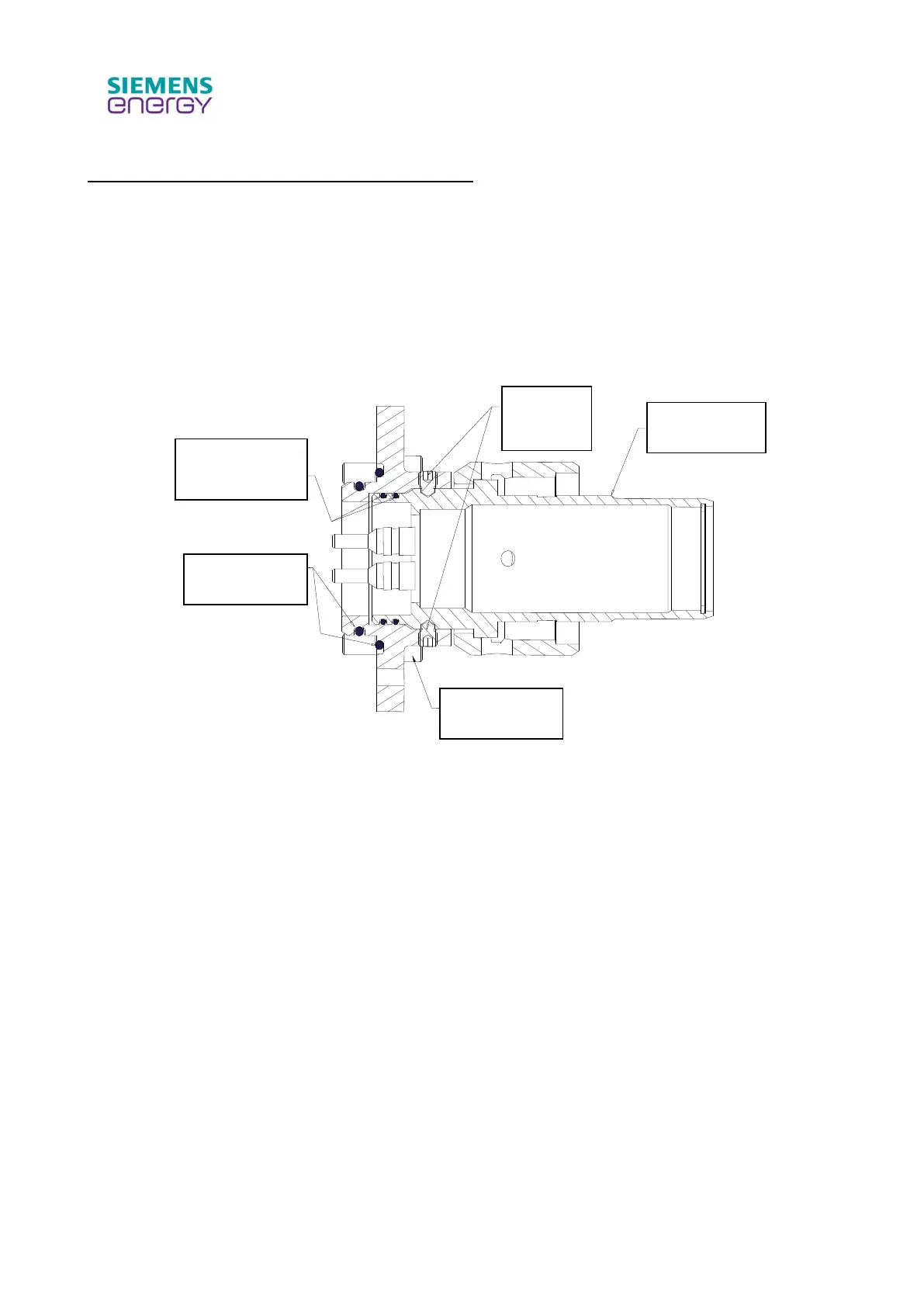

Installation of sealed bulkhead diver connectors

Referring to Figure 17, inspect ‘O’ ring grooves for damage and debris prior to installation of ‘O’ rings.

Apply a small amount of DC4 grease to the interface ‘O’ rings and install on the connector, fit

connector to interface ensuring correct orientation (unless otherwise stated ensure the key is at the

12-o’clock position).

Apply a spot of Loctite 243 to the threads of the cap head mounting screws and tighten to a torque

of 10-12Nm (7.38 – 8.85 lbf.ft) for metal to metal flange contact.

Figure 17 Sealed bulkhead diver mate plug connector

Bulkhead connectors with pigtail wires terminated should be treated with care, especially around the

termination area and the termination area should not be bent. Excessive force should not be used

to pull the wires. The connector should not be held or carried using the terminated wires.

Care must be taken to protect the tails on installation. The tails must be fed through the bulkhead

without damage or kinking occurring. The connectors must be installed so that once they are fitted

in place the tails will not be obstructed or snagged.

Loading...

Loading...