Disposal and recycling

7.3 Disposing of permanent magnets

A5E01083943A AB

88 Siemens AG Operating Instructions 2.02 1FW4

● Surge arrester

● Capacitors

Some components, such as the stator, contain a considerable amount of copper. This

copper can be separated from the electrical insulation via gasification of the organic binding

materials. To ensure proper burning of the vapors, the oven must have an appropriate

afterburner. The following conditions are recommended for heat-treating and afterburning in

order to minimize the emissions from the process:

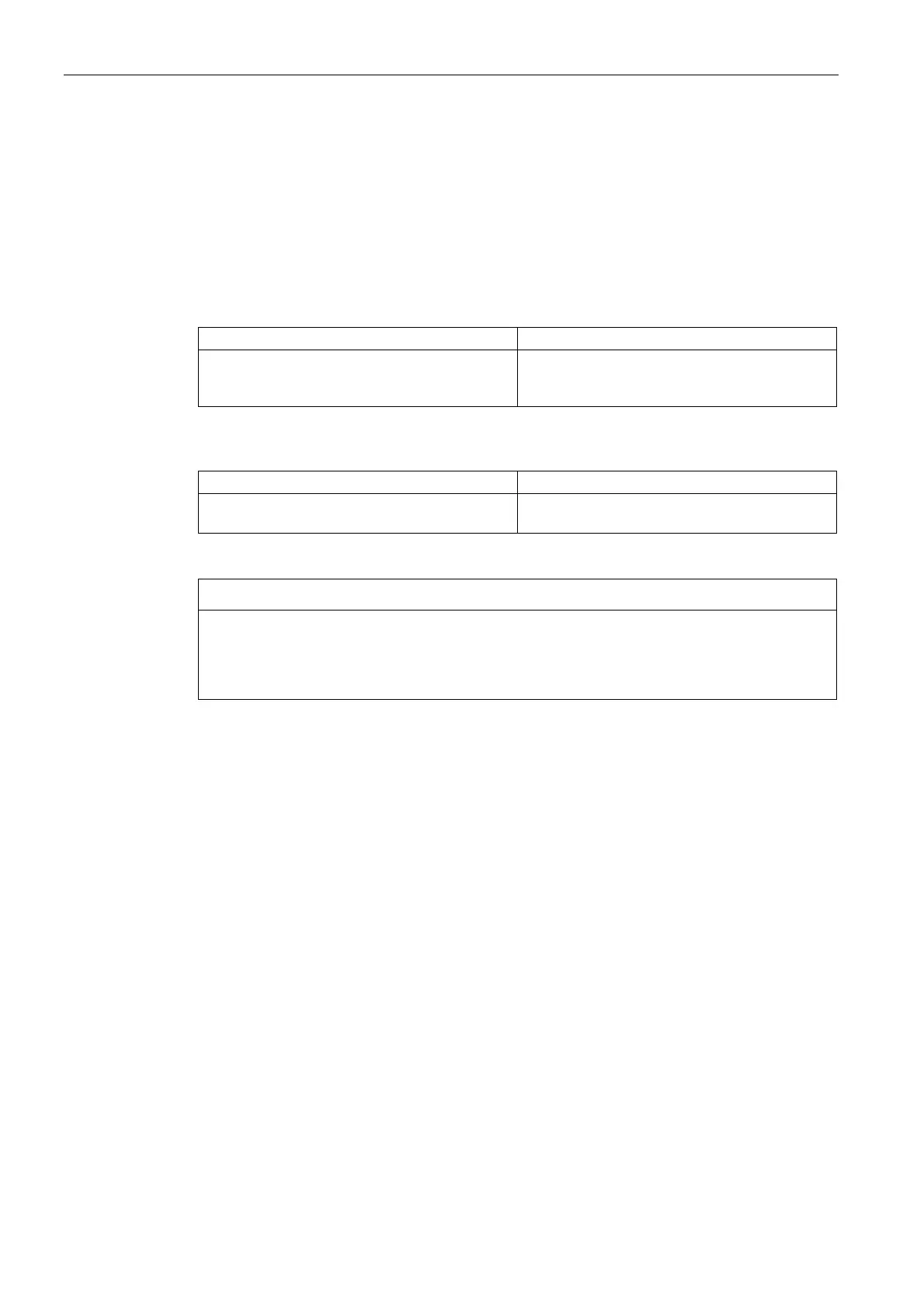

Table 7-1 Heat treating

Temperature 380 - 420°C (716 - 788°F)

Duration Once 90% of the target temperature has been

reached, the object must be kept at that

temperature for at least five hours.

Table 7-2 Afterburning of the binding material vapors

Temperature 850 - 920°C (1562 - 1688°F)

Flow velocity ° The binding material vapors must remain in the

combustion chamber for at least 3 seconds.

NOTICE

Emissions

The emissions primarily consist of O

2

-, CO-, CO

2

-, NO

x

-, C

x

H

y

gases and microscopic

particles. It is the responsibility of the owner/operator to ensure that the process complies

with local laws.

Anti-corrosion agents

Anti-corrosion agents that cover the motor's surface can be cleaned using a gasoline-based

cleaning agent and a rag. Dispose of the rag in accordance with local regulations.

[ID 825.01]

7.3 Disposing of permanent magnets

If the motor is completely melted down, no special handling of the permanent magnets is

necessary. Remove all cables before the melting process.

Description

If the 1FW4 motor is removed and dismantled, the permanent magnets must be

demagnetized. To do this, the motor must be heated to 350°C. This is necessary to ensure

that no hazards result from the rotors during and after disposal. The disposal process must

be performed by a specialized disposal company.

Loading...

Loading...